PET Bottles Recycling

From PET bottle flakes/ BOPET film/ Polyester filament to PET pellets

Why is Recycling PET Bottles Important?

Due to the current inability of plastic to decompose in the environment, it can cause significant pollution to the ecosystem. For example, PET bottles are a major source of plastic waste and may take hundreds of years to decompose in landfills. Recycling PET bottles reduces the amount of waste entering landfills and helps to protect natural resources by reducing the demand for virgin materials.

Furthermore, using recycled materials to produce new plastic only uses two-thirds of the energy required to manufacture raw materials. The energy saved from recycling a single plastic bottle is enough to power a 60-watt light bulb for approximately three hours. Therefore, recycling products like plastic bottles provide tremendous business opportunities.

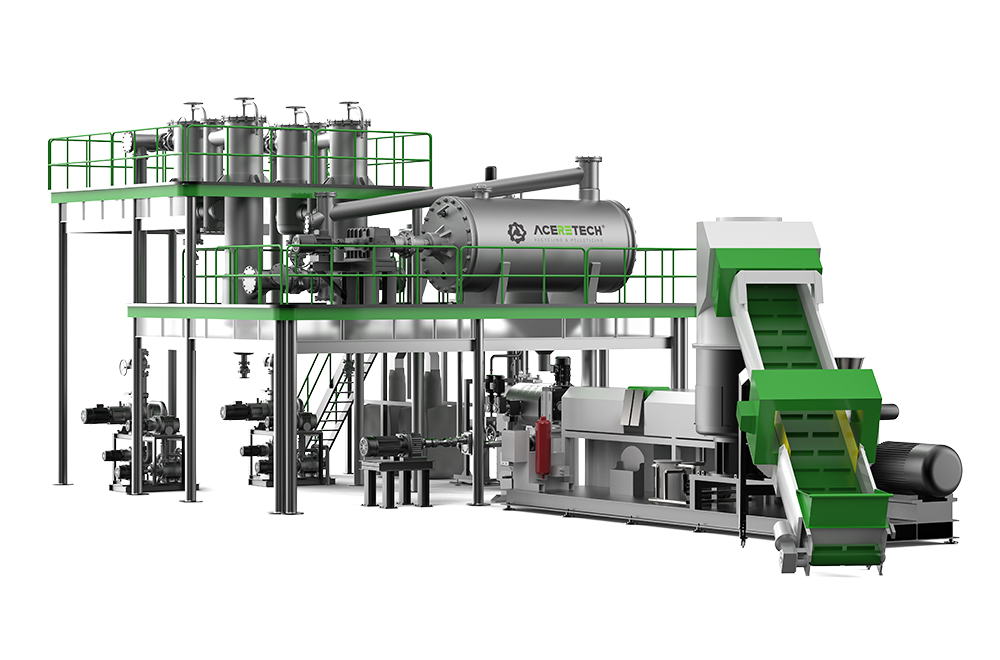

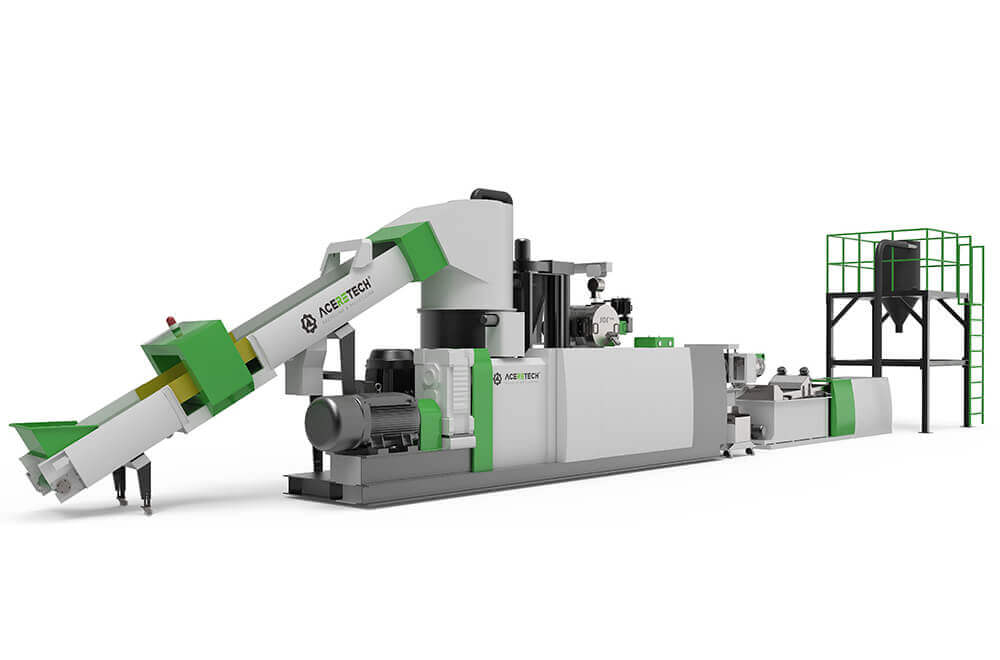

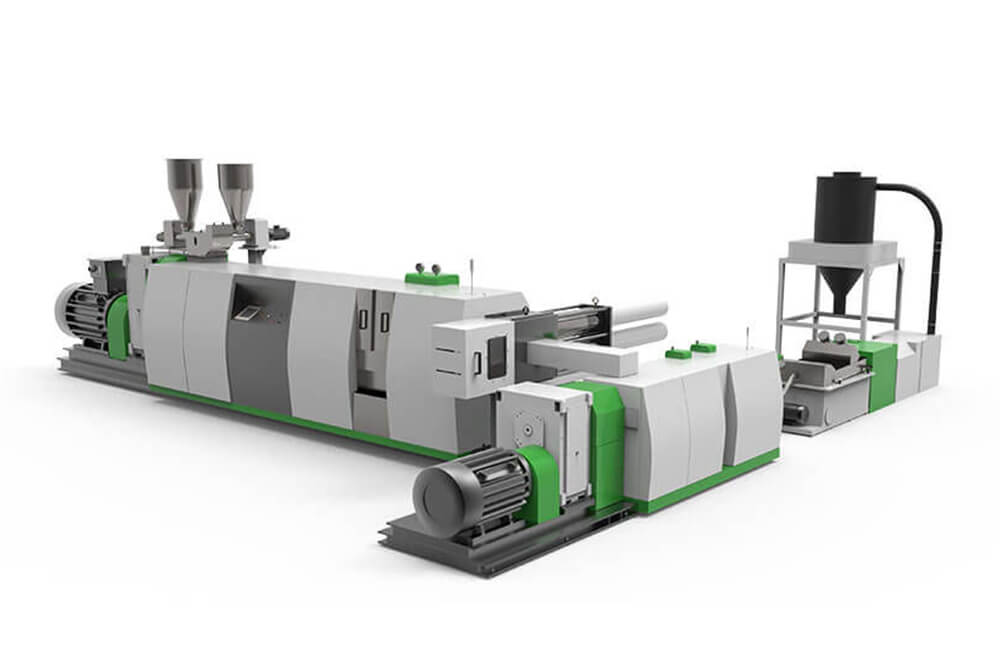

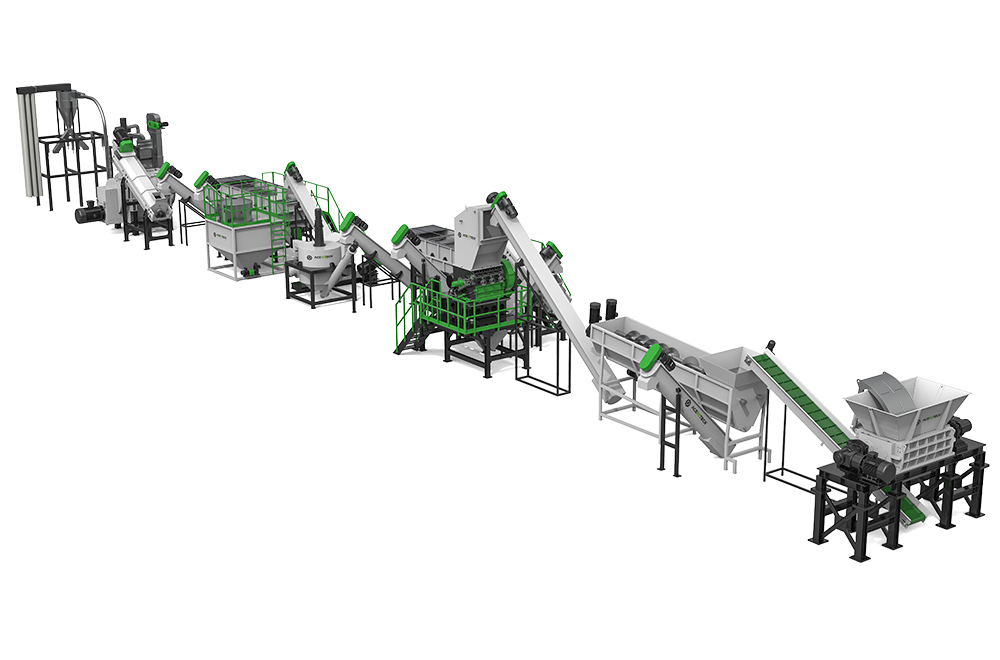

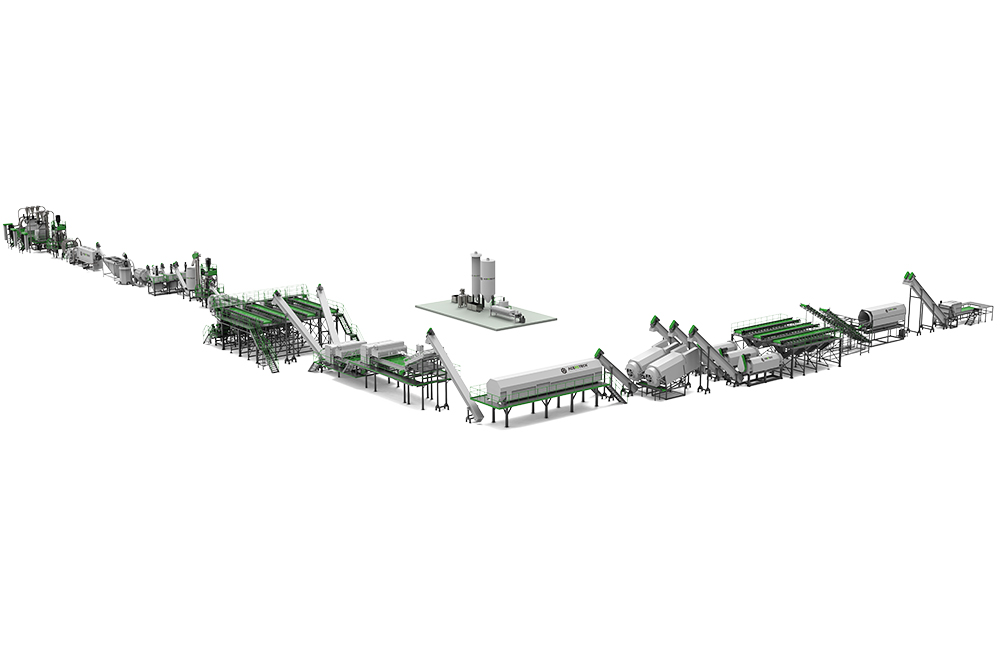

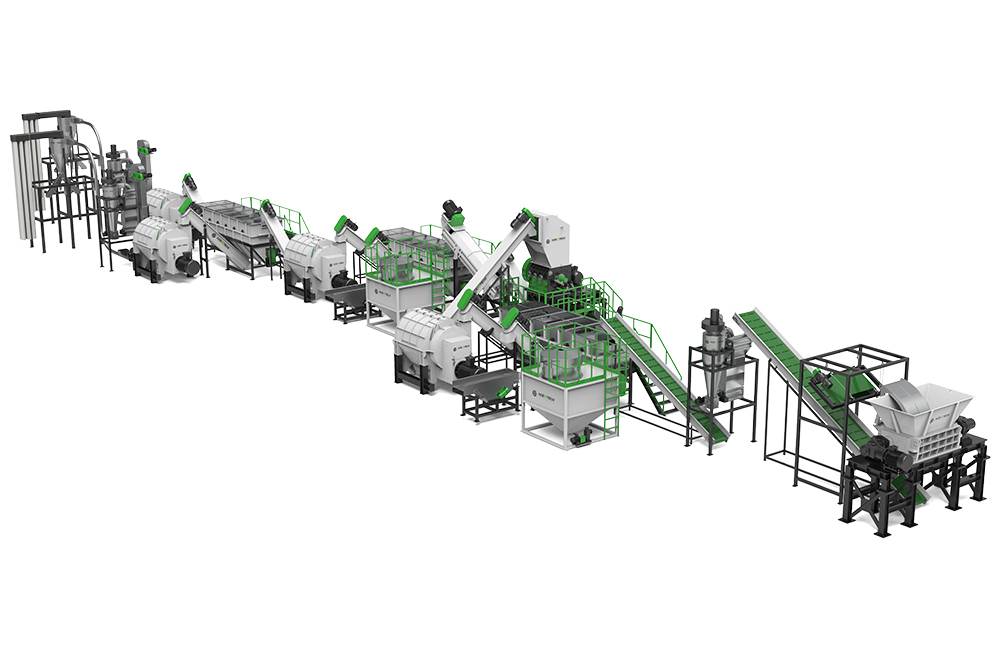

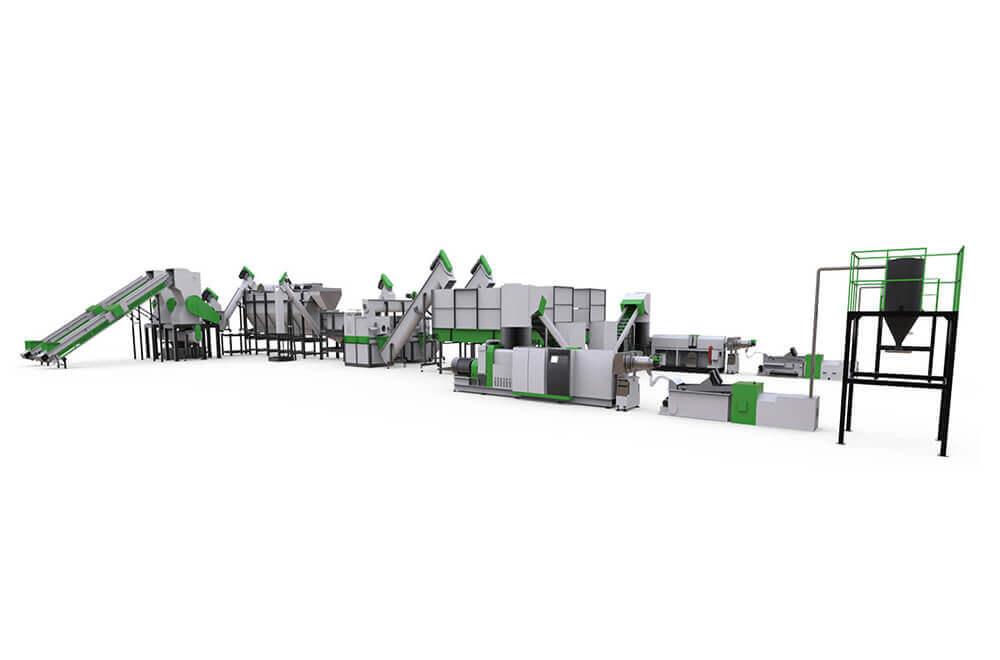

Integrated Solution for Recycling PET Bottles

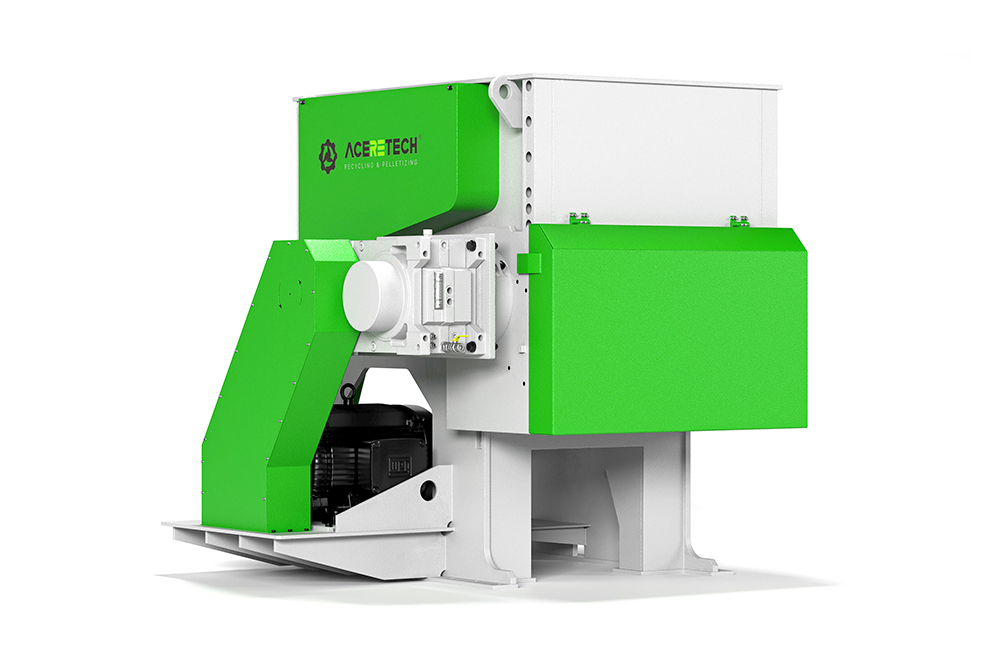

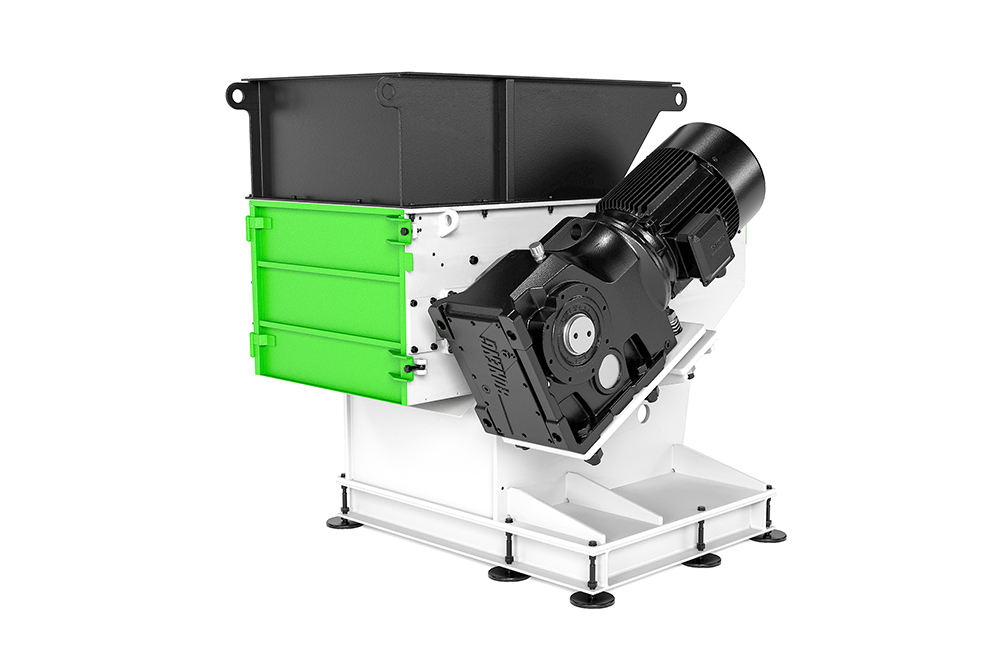

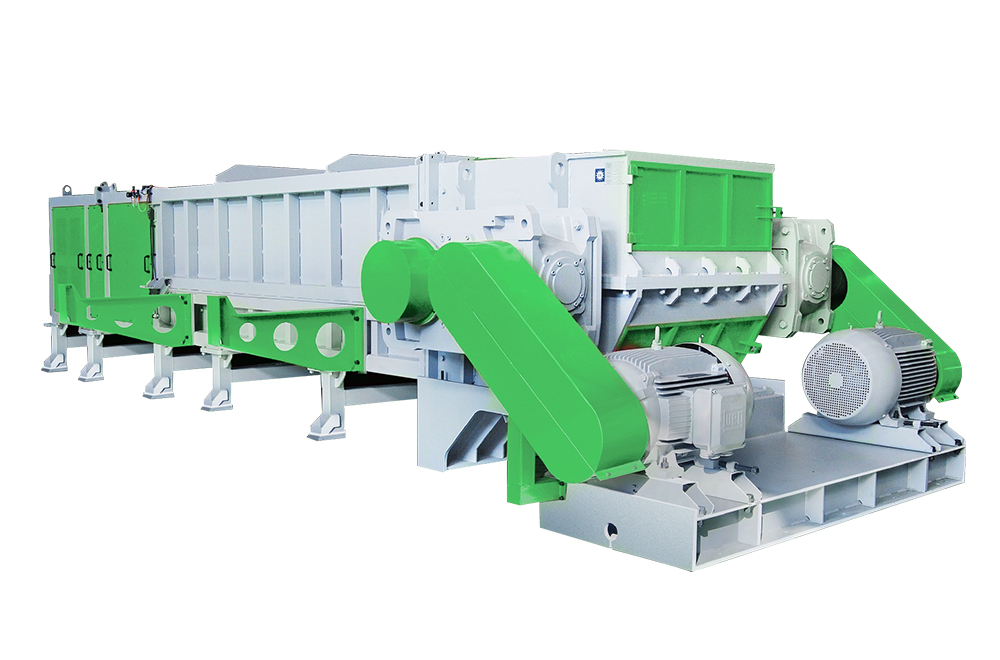

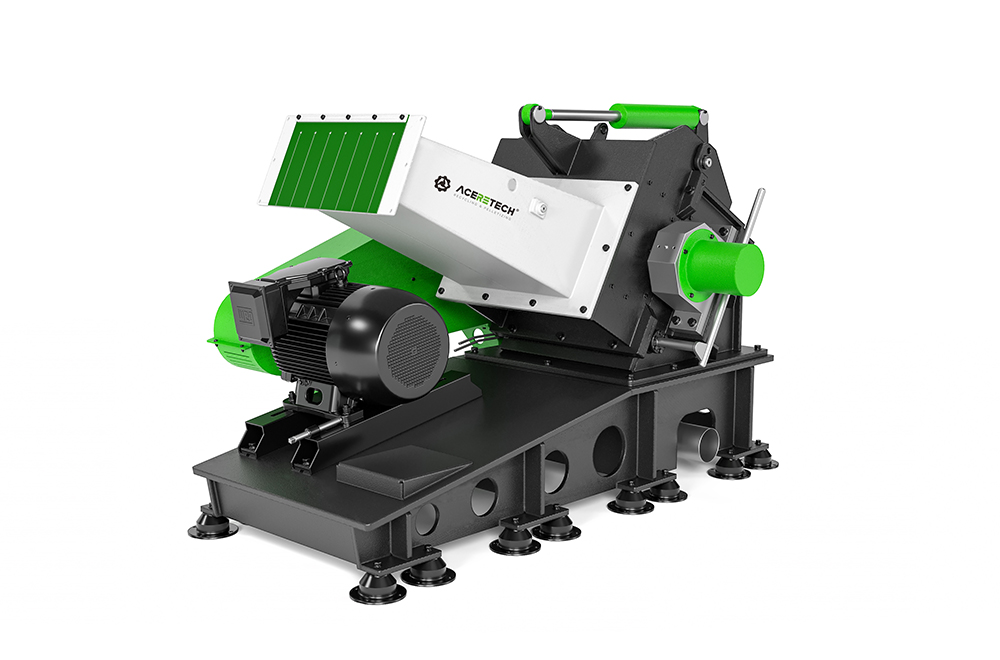

Aceretech's complete PET bottle recycling line is the best solution for anyone. This fully automatic turnkey solution can process packaged PET bottles into pollution-free PET sheets. These plastic sheets can be sold at high prices to polyester short fiber manufacturers or cut into pellets for the production of other PET products.

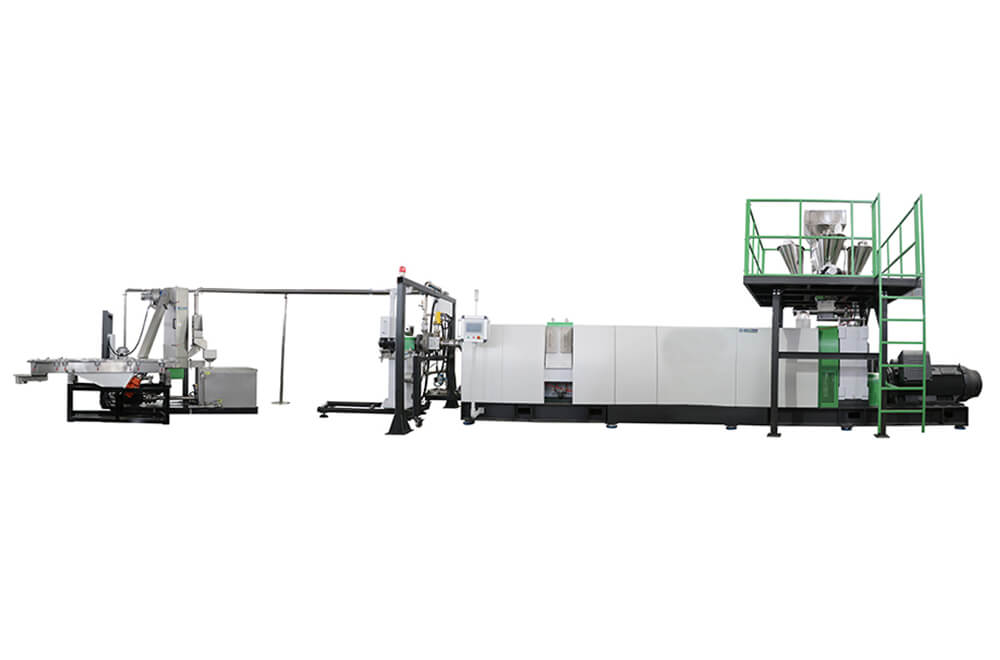

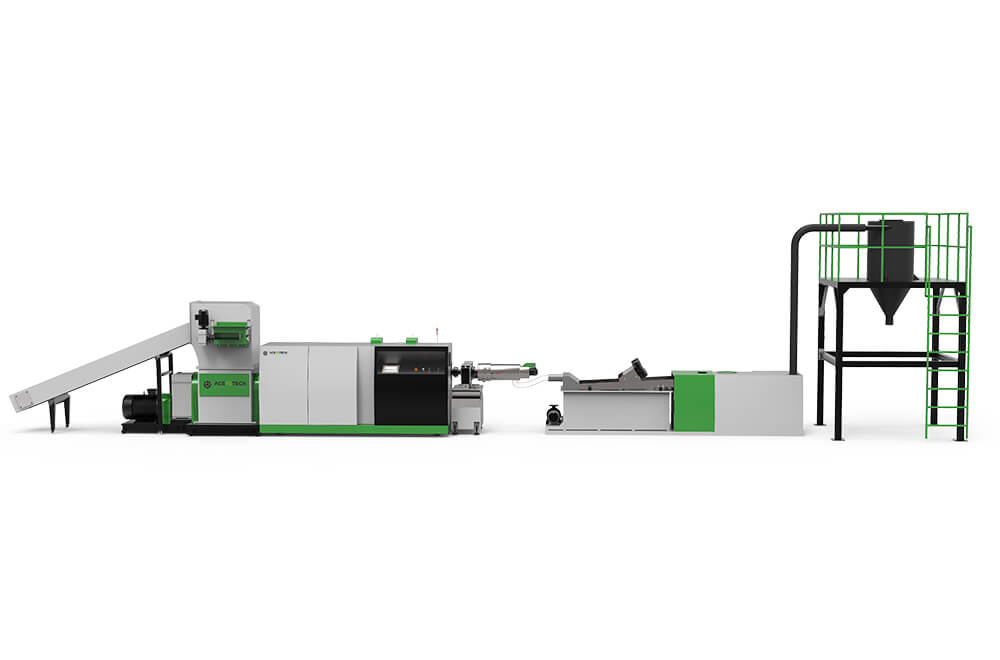

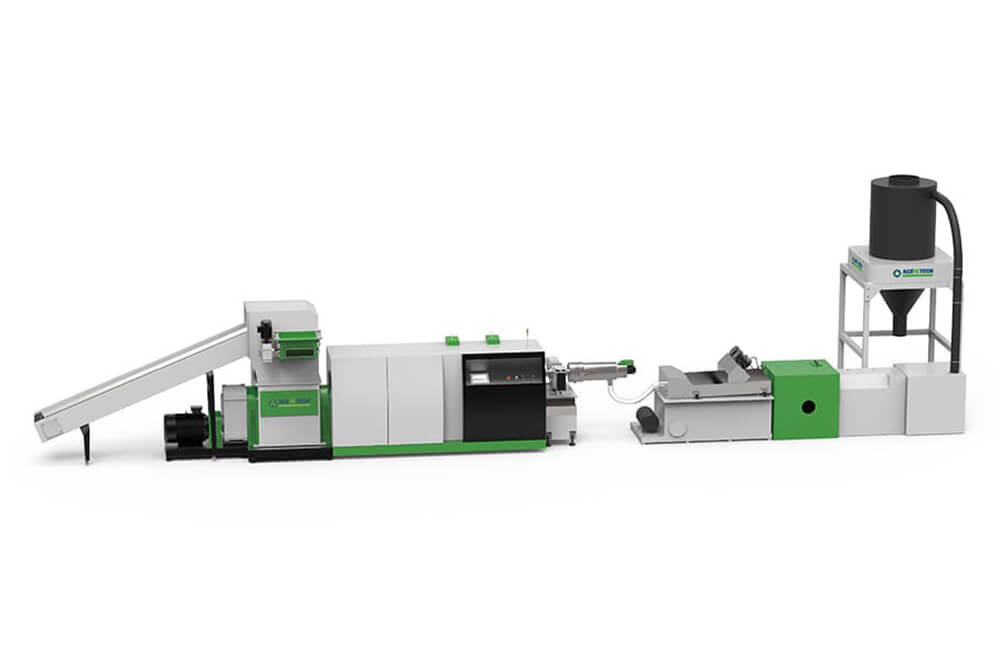

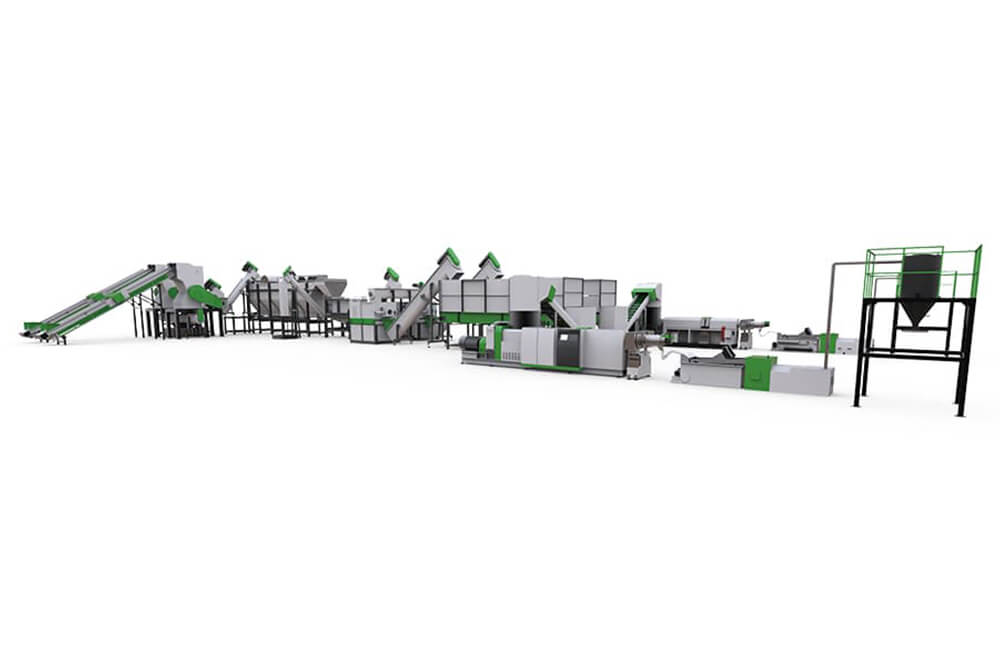

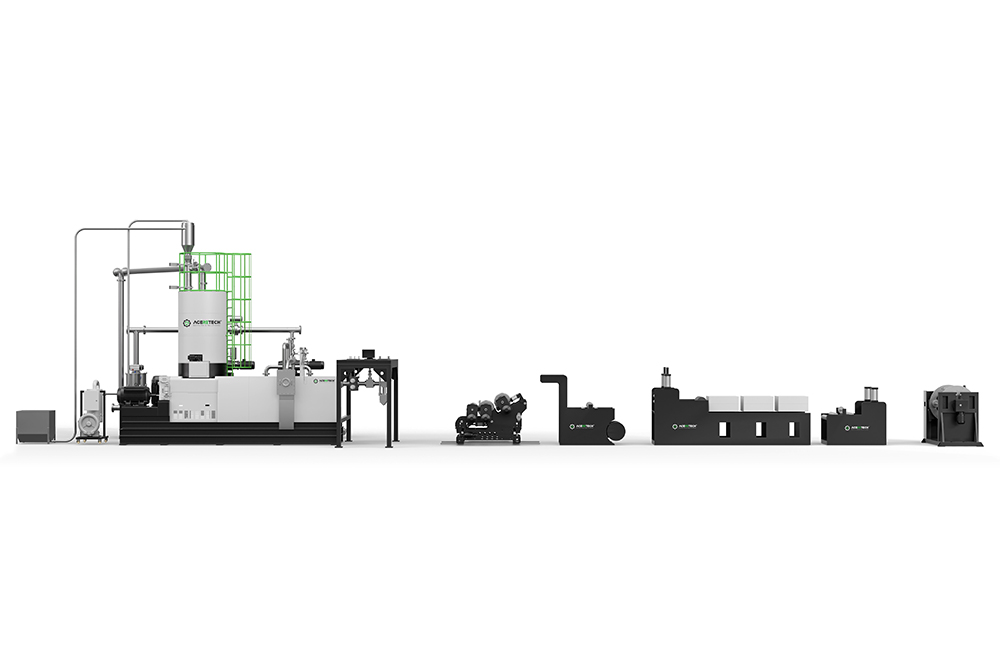

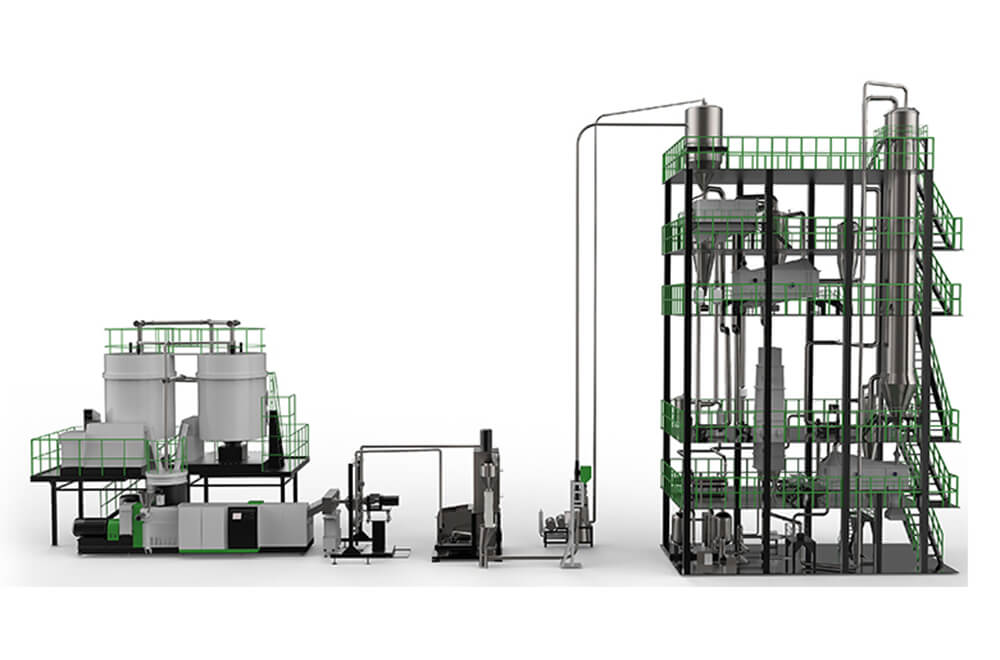

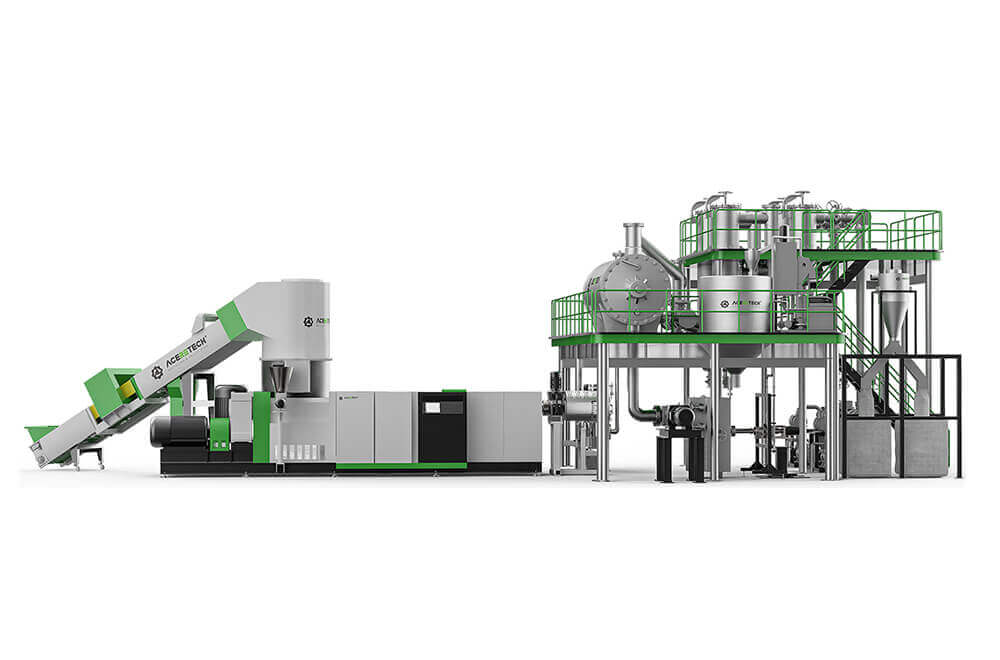

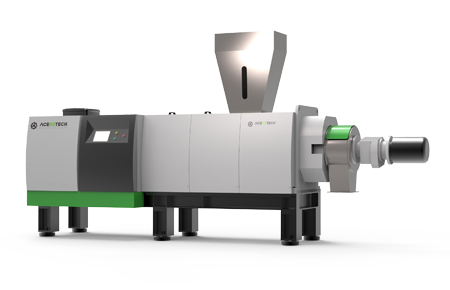

ACS series of pelletizing line with thermo compactor could recycle PET bottle flakes, BOPET film, polyester filament to valued PET pellets well.

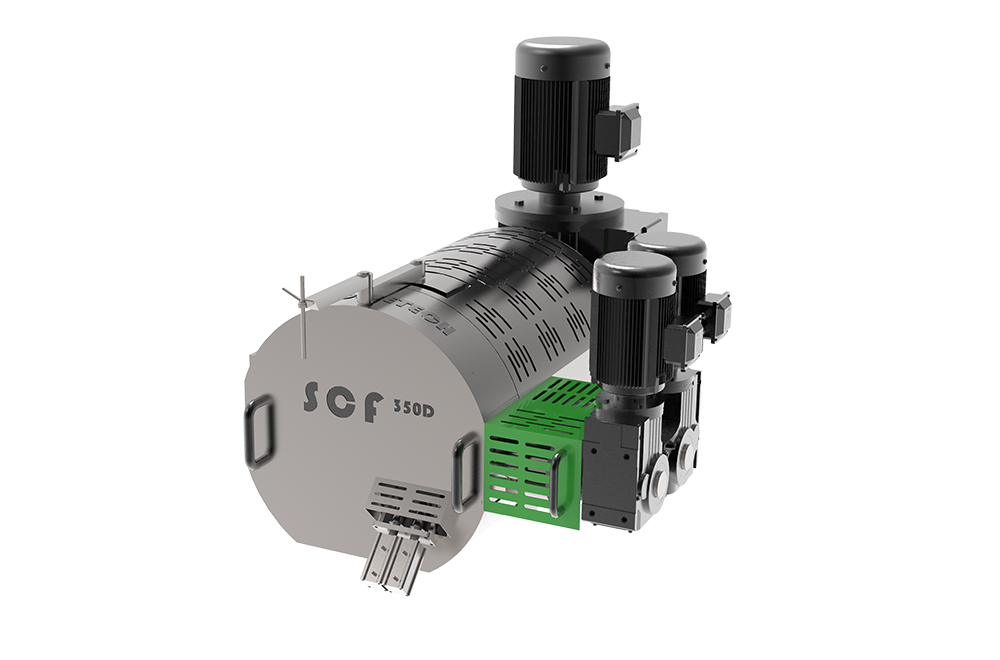

1. Compactor: special crystallization and drying function in the compactor.

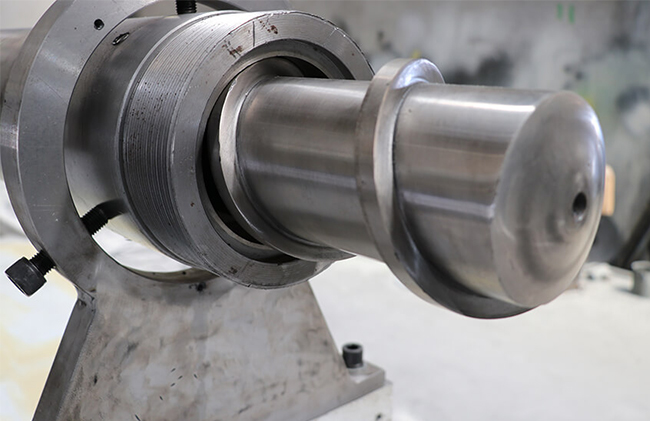

2. Gentle melt and plastifization in the single-screw extruder.

3. Strong vacuum degassing system.

4. Strand pelletizer/ more advanced fully automatic strand pelletizer (no need manual adjustment of strands.)

5. Pellets drying system: vibrosieve, centrifugal dryer.

6. Throughput up to 1T/h.

Video for rerefence : https://youtu.be/Y2fa8L3PQ3E

The increased environmental awareness in China represents a huge opportunity for manufacturers of plastic recycling machinery. Plastic recycling is growing enormously in importance and significance, particularly in China. The global shortage of raw materials, rising cost pressures, and large amounts of waste mean that the recycling market is developing rapidly.

Waste PET bottles can be recycled, pelletized and reused to produce new PET bottles, containers, fiber applications such as carpet and apparel. ACERETECH launches a series of high performance PET Bottles Recycling Plants. If you are interested or have any question, please do not hesitate to contact ACERETECH and we will reply ASAP.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us