Twin Screw Extruder Compounding & Recycling

Twin screw extrusion machines are a type of equipment that can process and recycle plastic waste by using a twin screw design. Plastic recyclers can use twin screw extrusion machines to turn plastic waste into useful products. These double screw extruders have many advantages, such as higher efficiency and productivity, more flexibility in handling different plastics, better quality of recycled products, lower energy use, and less waste.

Reliable Partner in Double Screw Recycling Extruders

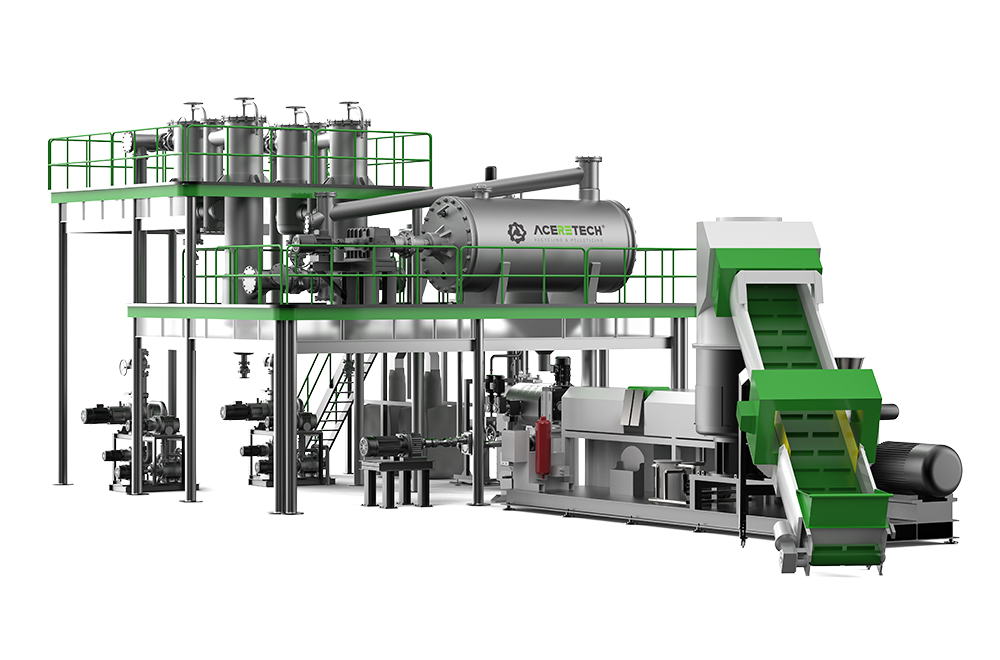

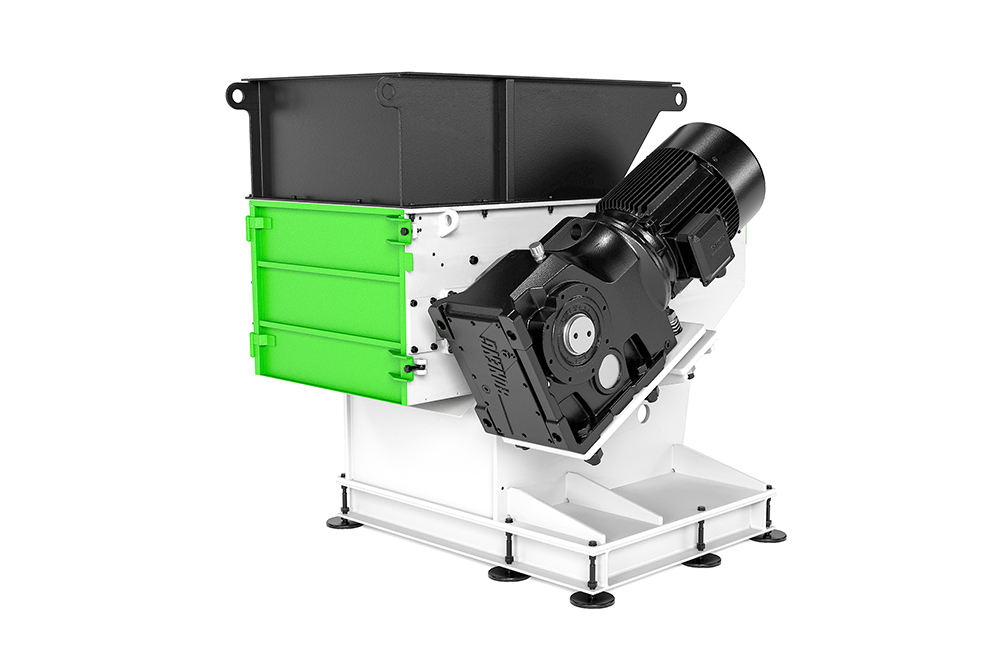

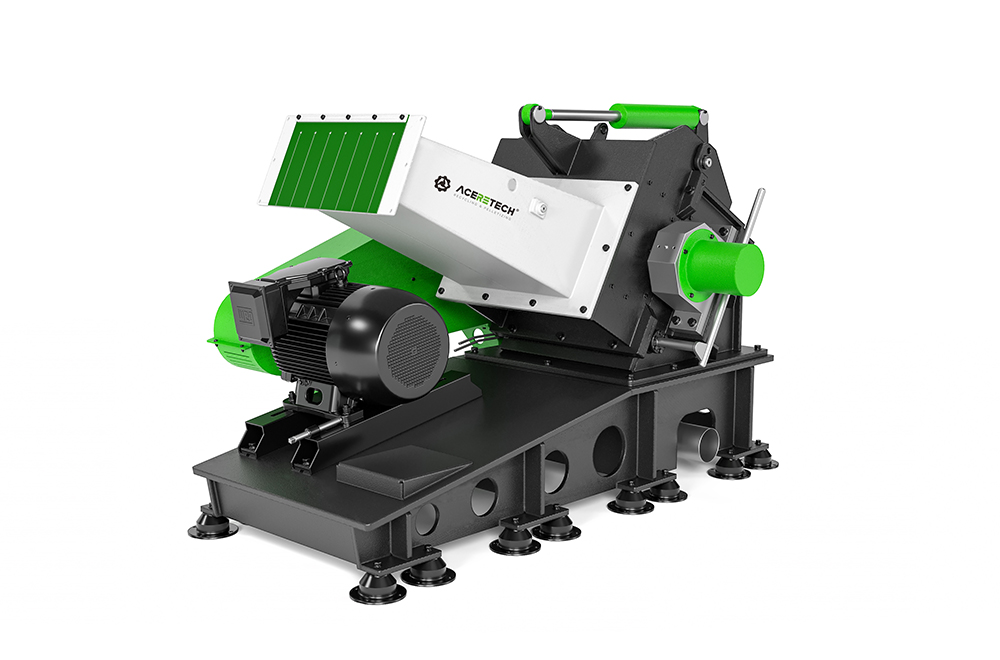

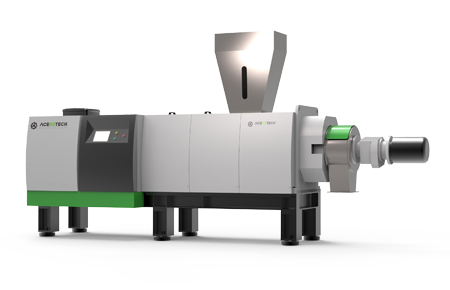

ACERETECH is a leading brand in the recycling industry, offering a wide range of twin-screw extruders designed to handle the most diverse waste plastic recycling applications. With a focus on precision, quality, and flexibility, ACERETECH machines are engineered to help you innovate and lead in your field.

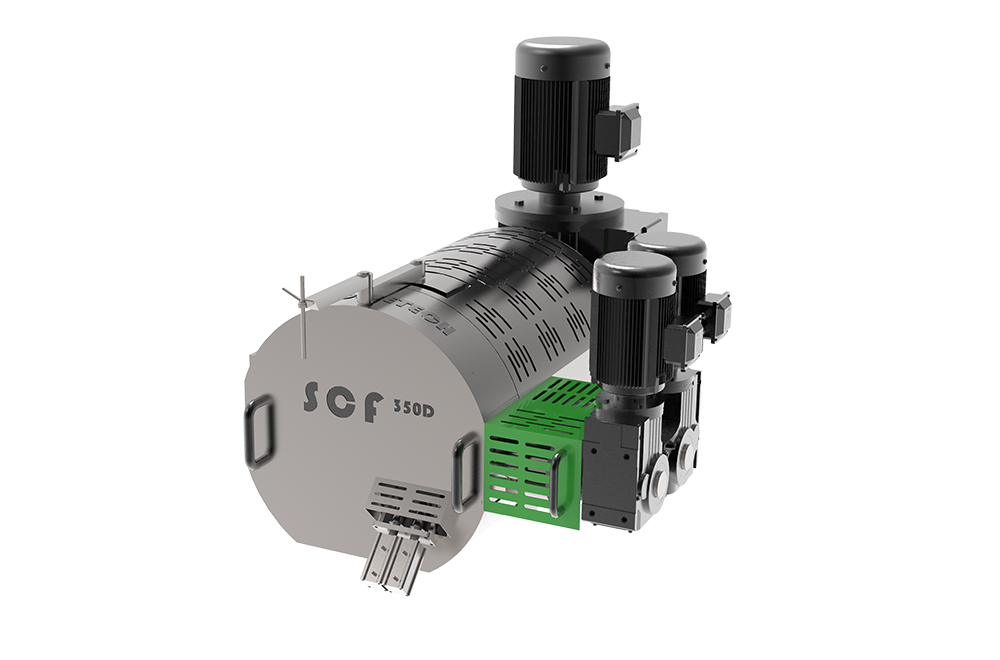

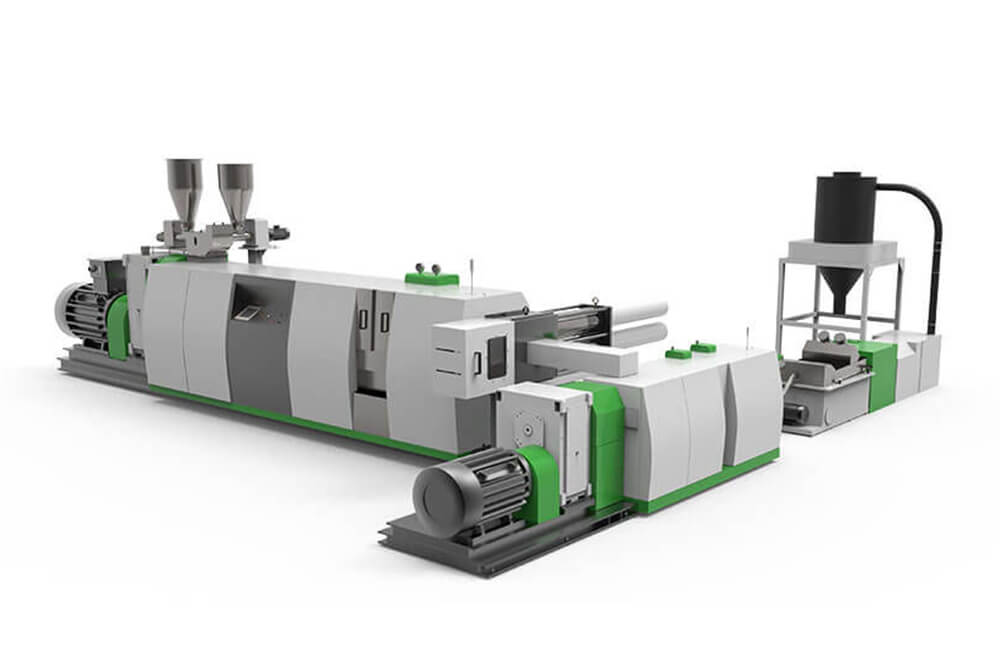

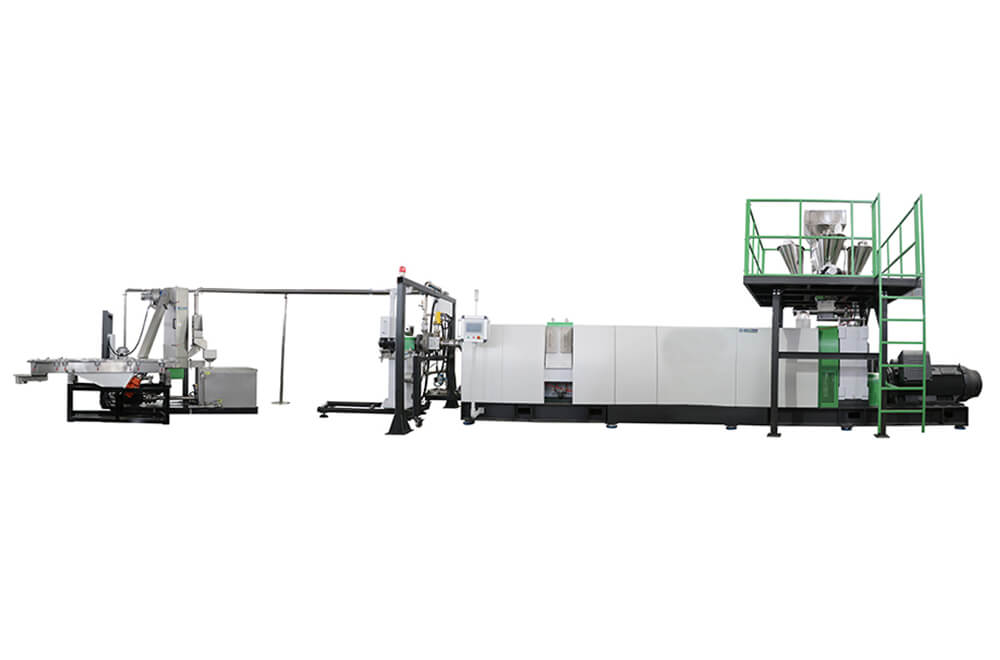

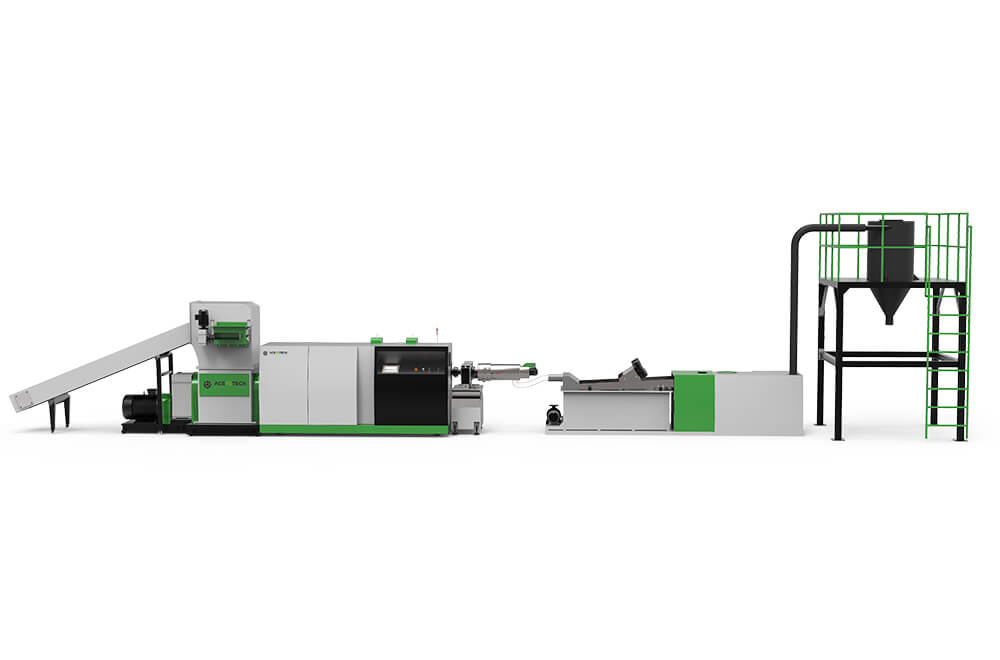

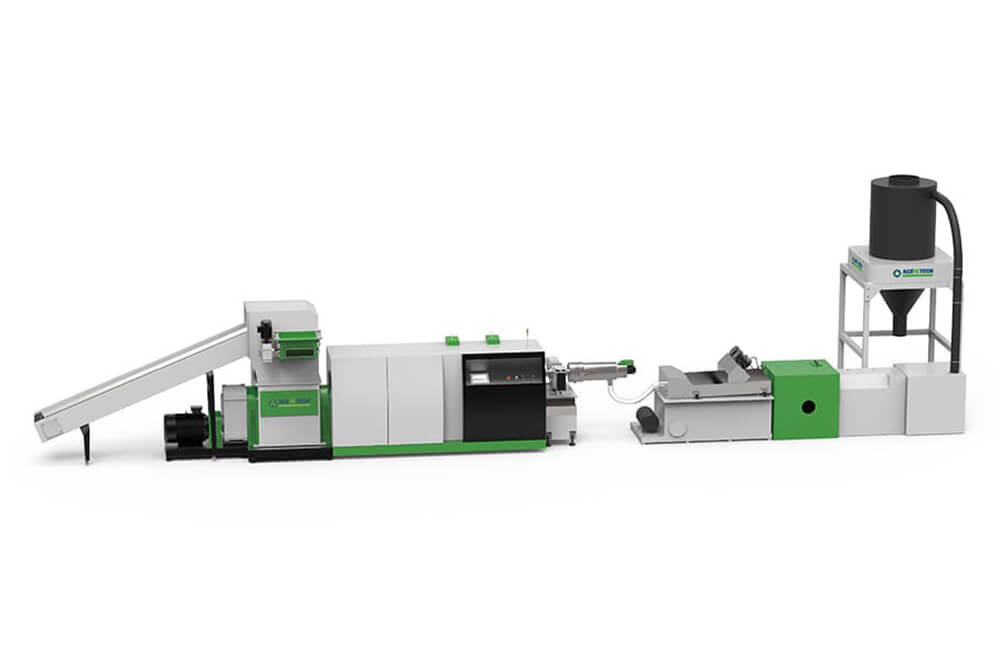

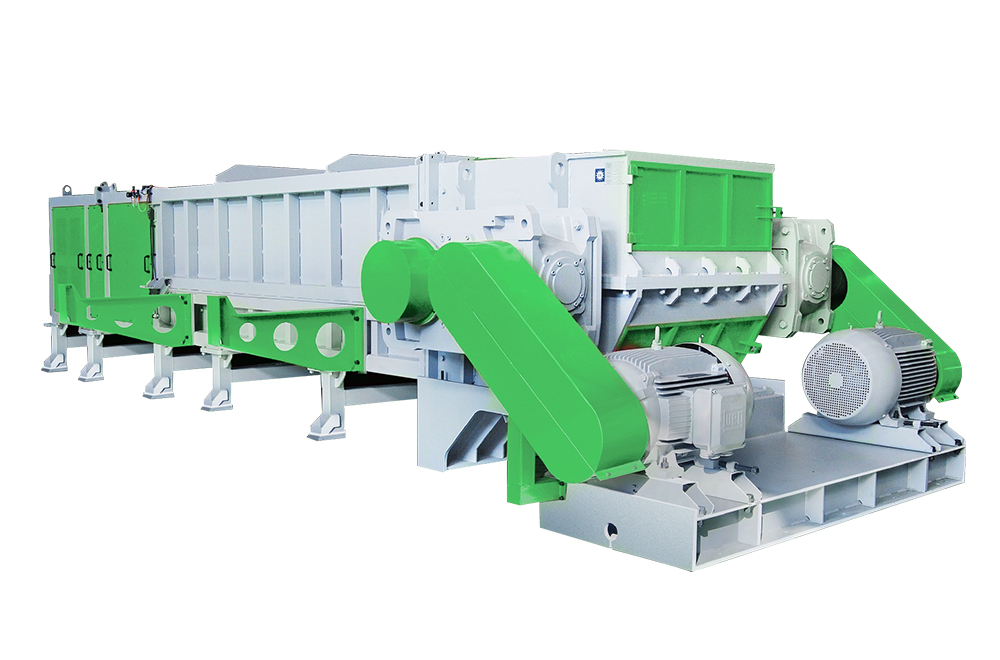

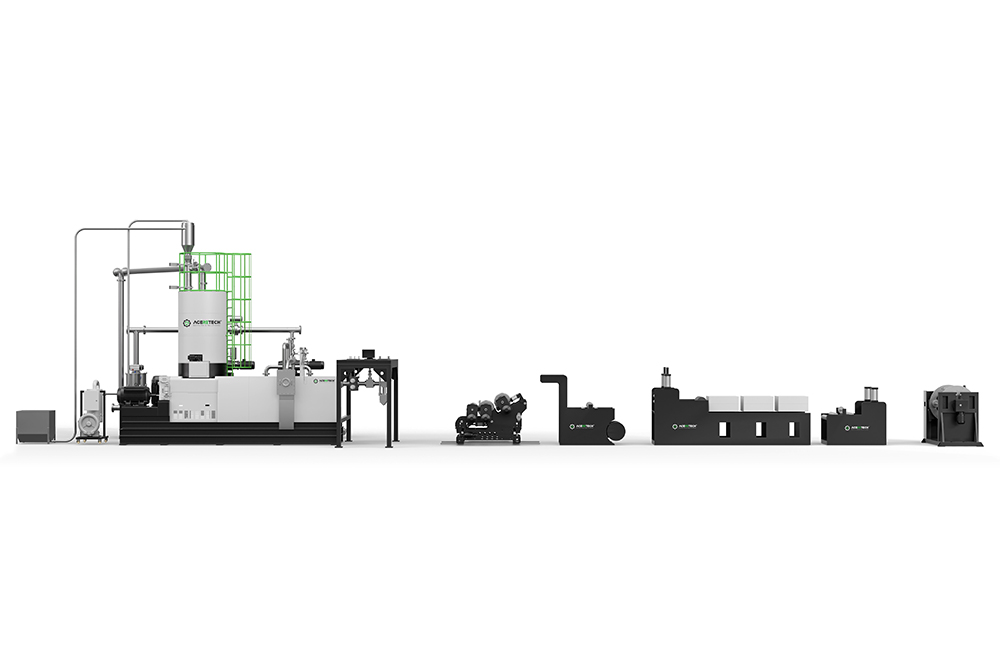

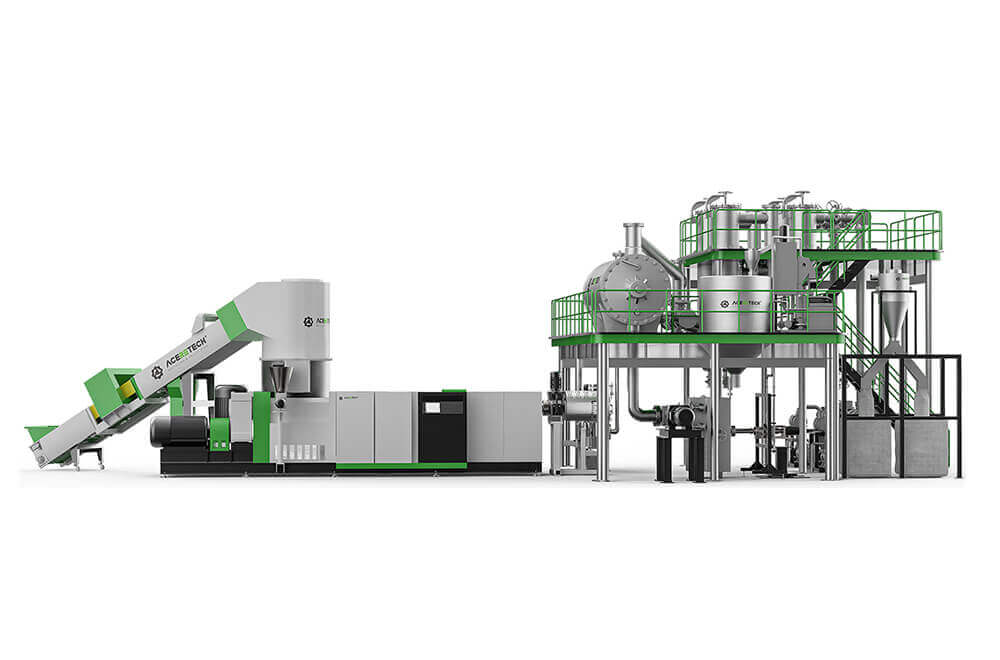

ACERETECH's twin-screw extruders are expertly engineered and rigorously tested to handle a range of industrial applications that require kneading, dispersive mixing, distributive mixing, and reactive extrusion. Our extruders are designed with closely intermeshing self-wiping co-rotating screws for mixing, along with modular segmented barrel sections and various types of screw elements for maximum flexibility and cost-effectiveness.

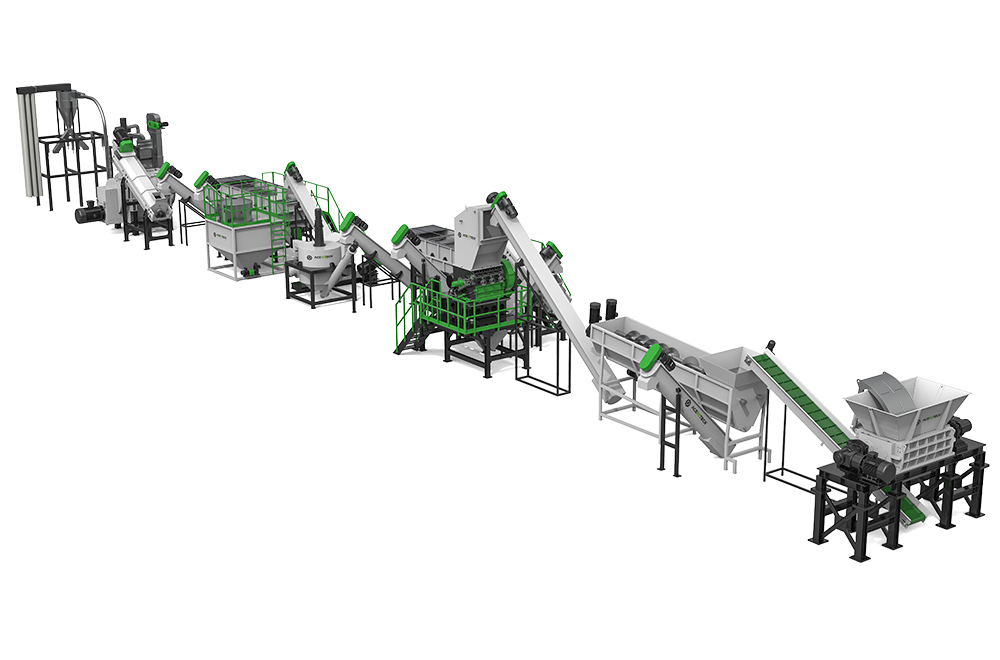

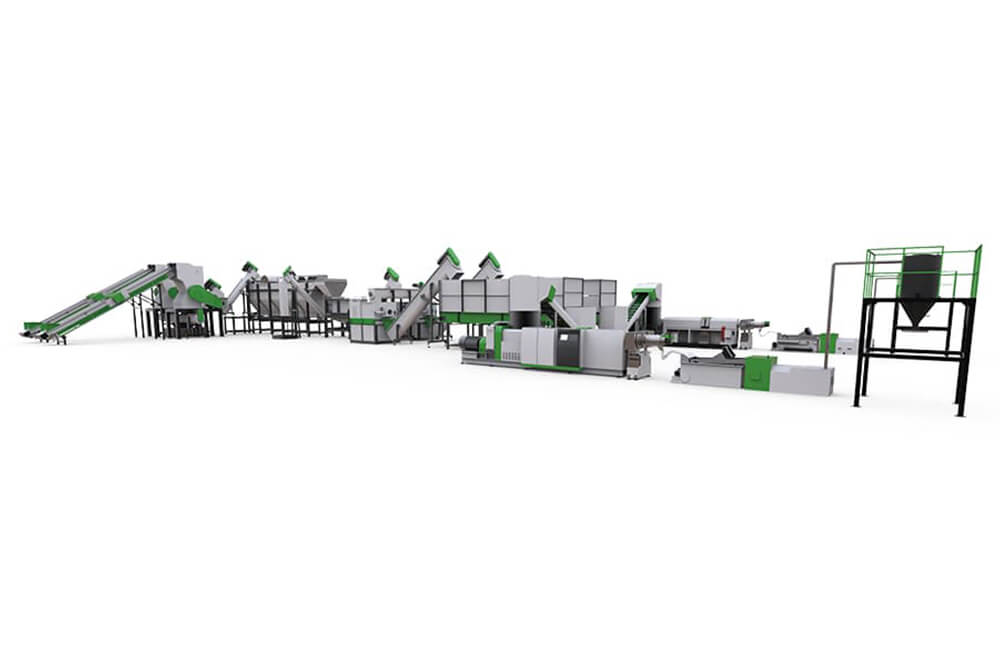

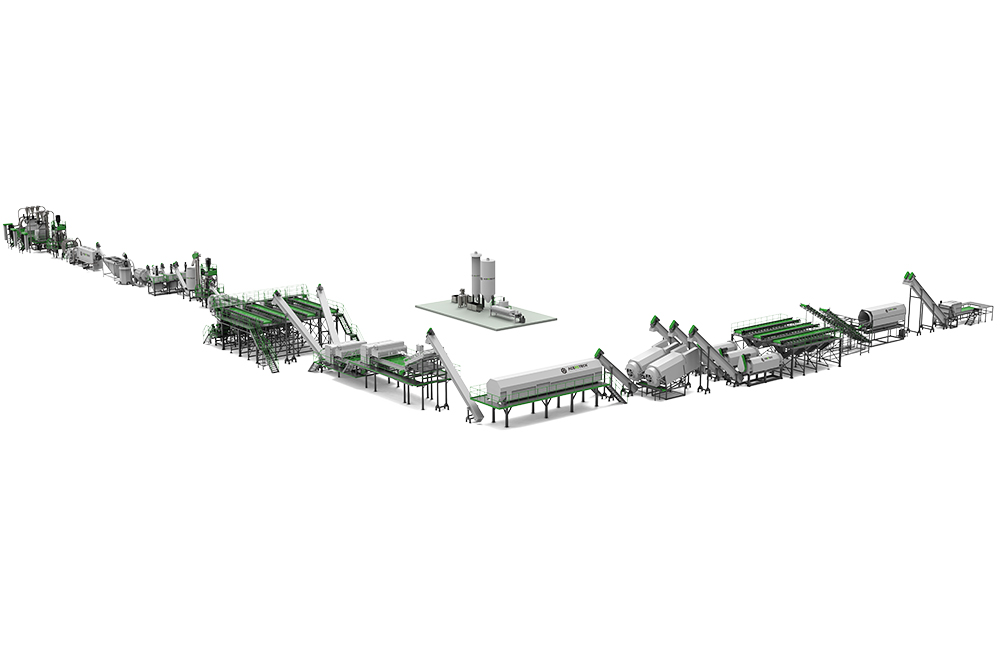

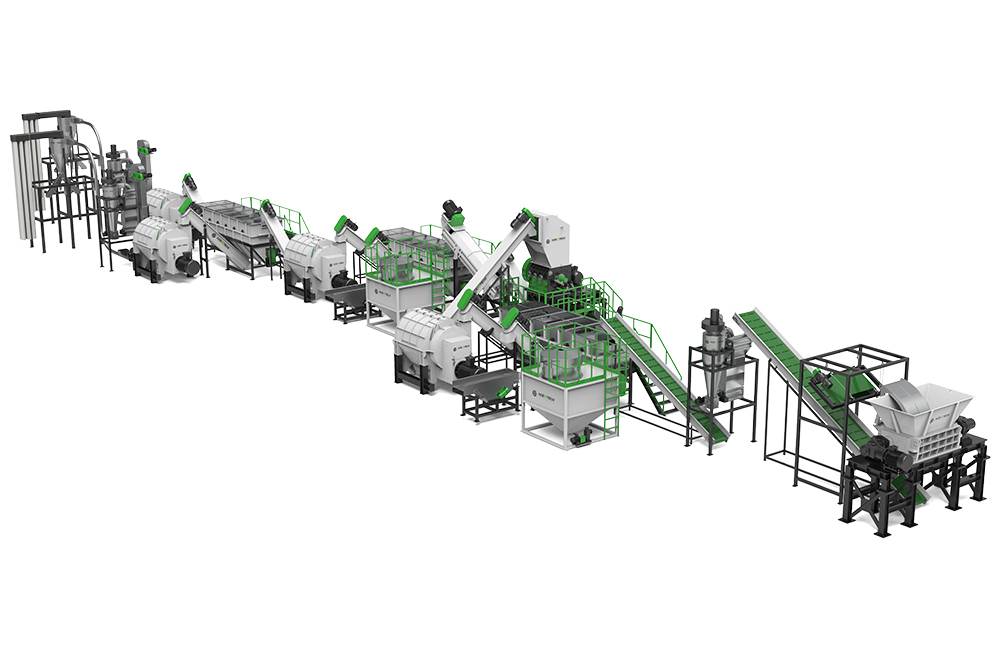

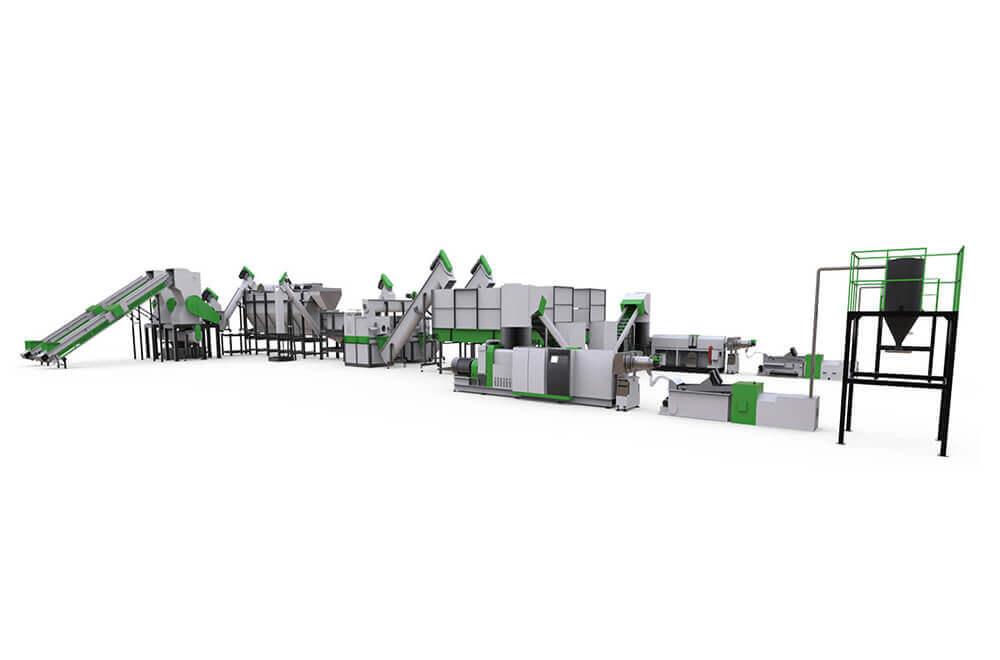

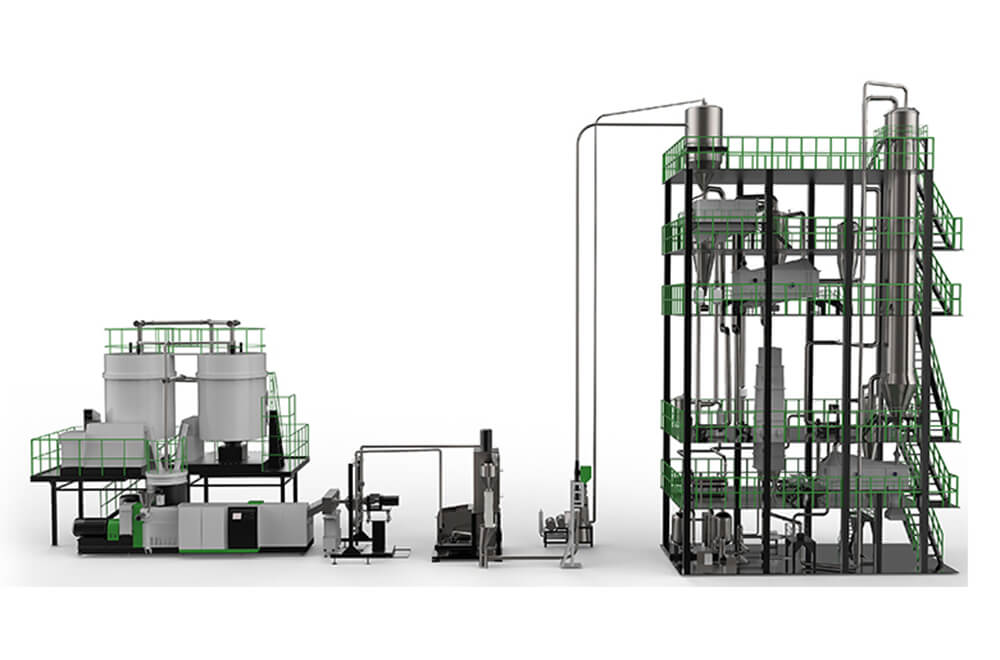

In addition to our extruders, we offer a complementary range of ancillary equipment and customized control system integration to provide a comprehensive and optimized turnkey solution for your compounding and mixing needs. With our coherent design, planning, and execution, you can trust that our system components are harmonized with each other for maximum efficiency and performance.

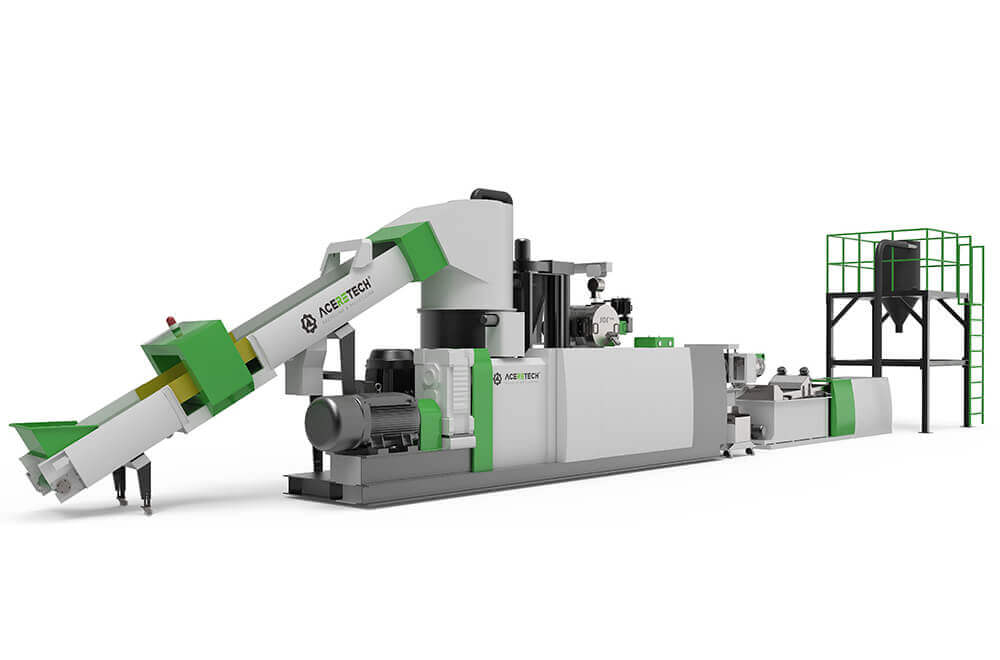

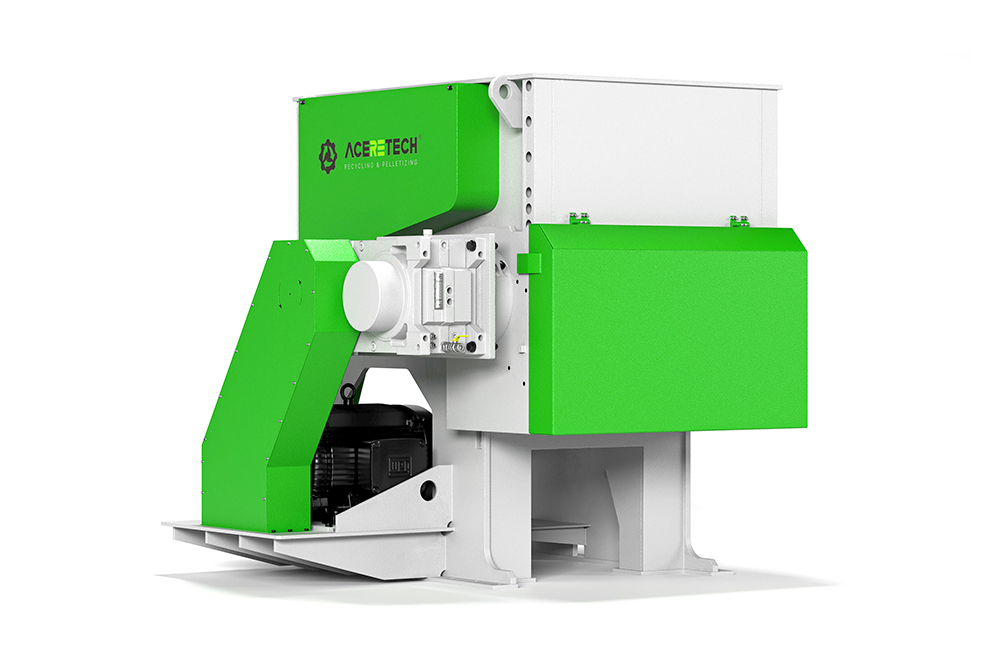

ACERETECH offers a range of twin-screw plastic extruders in various sizes suitable for lab-scale testing, pilot and small production runs, and large-scale manufacturing. Our extruders are equipped with specially adapted upstream equipment for feeding and downstream equipment for pelletizing after mixing, further expanding their capabilities into complete systems.

No matter which plastic or rubber you want to recycle, ACERETECH twin-screw extruder machines provide the power, precision, and flexibility you need for high-quality compounding and mixing. In conjunction with our other recycling-related equipment, ACERETECH's one-stop recycling line can make the entire recycling process more efficient and environmentally friendly. Trust our expertise and experience to help you innovate and lead in recycling.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us