- About Us

- News

-

Products

-

Products list

-

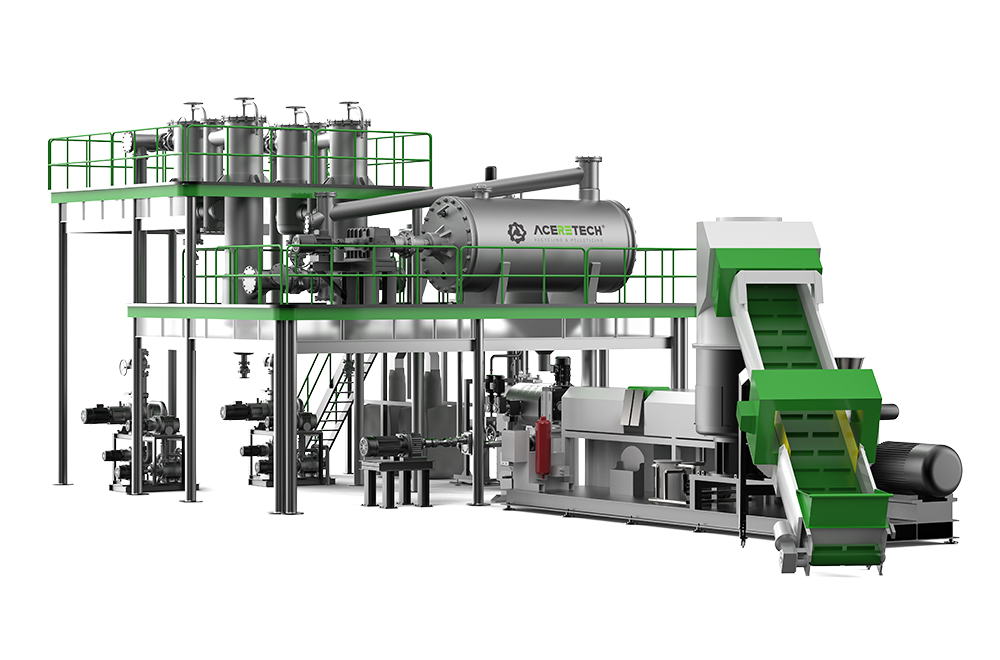

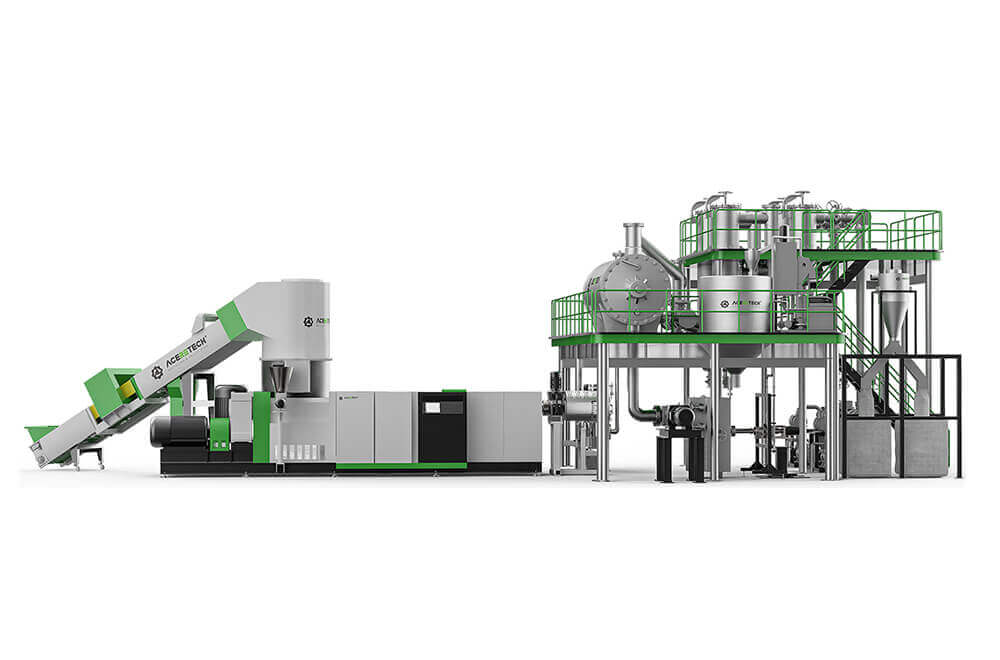

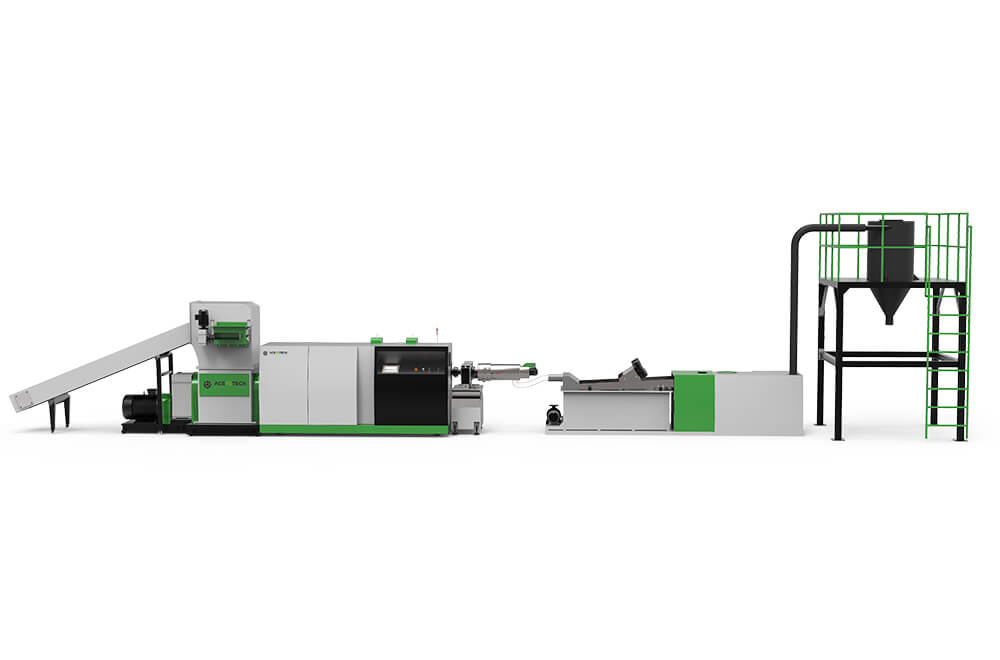

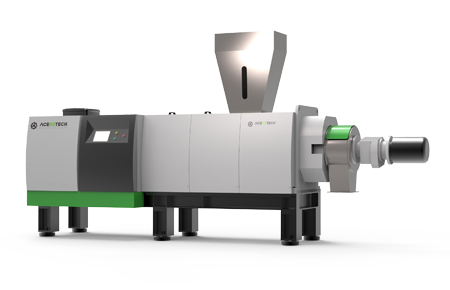

.jpg) Cutter Compactor Recycling Pelletizing System

Cutter Compactor Recycling Pelletizing System -

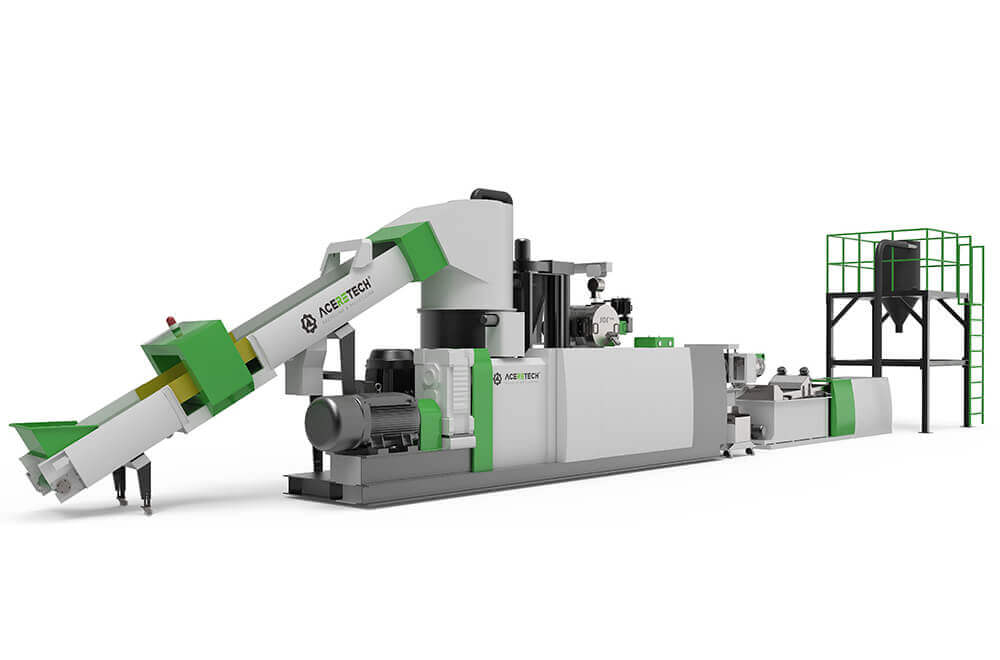

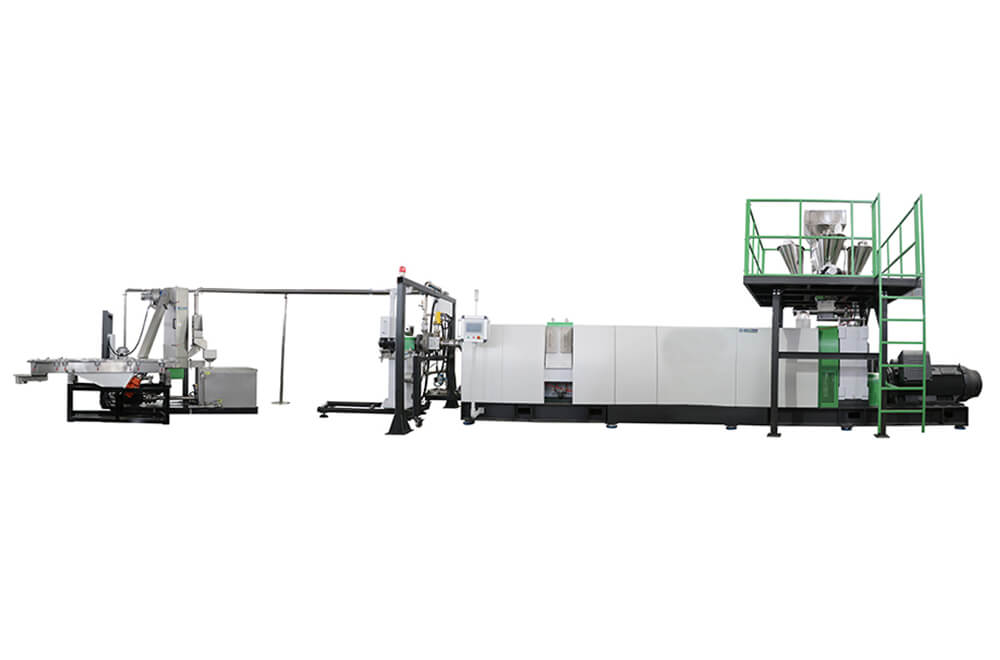

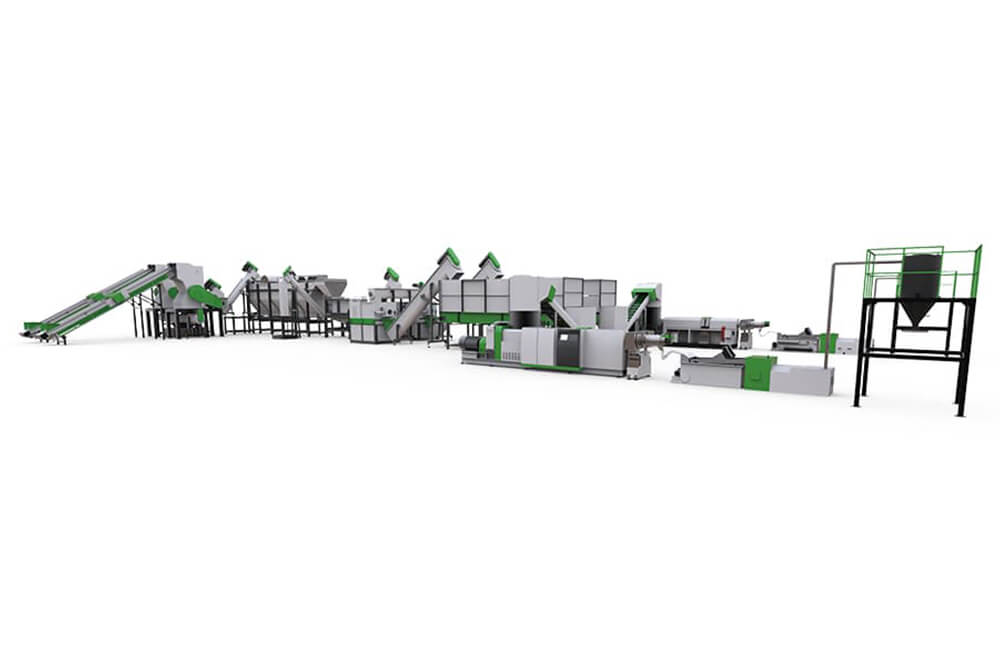

Single Screw Extruder Recycling Pelletizing System

Single Screw Extruder Recycling Pelletizing System -

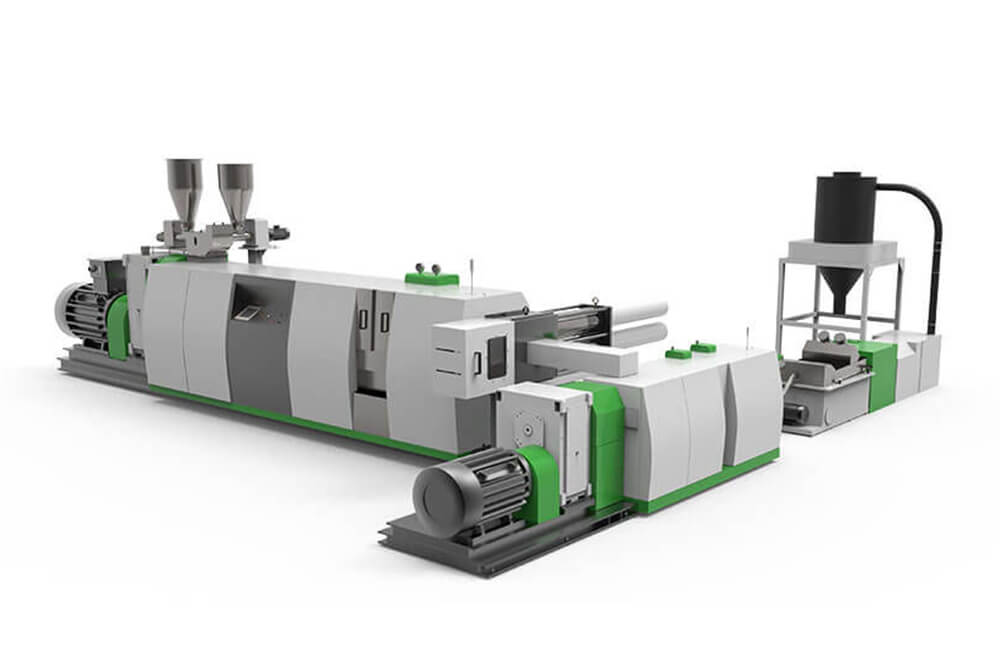

.jpg) Twin Screw Extruder Compounding & Recycling

Twin Screw Extruder Compounding & Recycling -

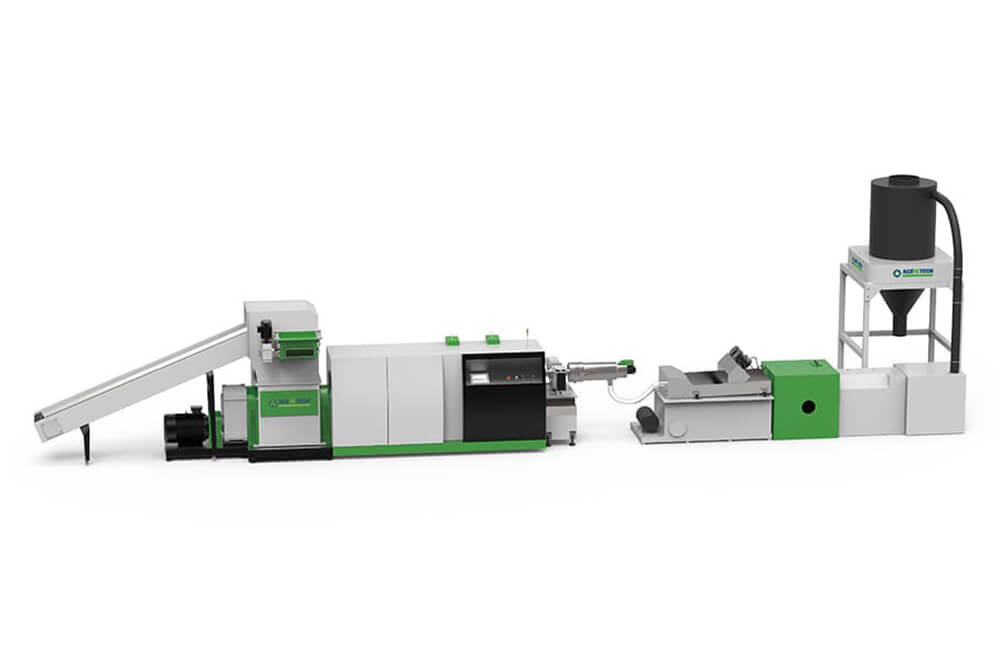

Shredder Extruder Recycling Pelletizing System

Shredder Extruder Recycling Pelletizing System -

Crusher & Shredder

Crusher & Shredder -

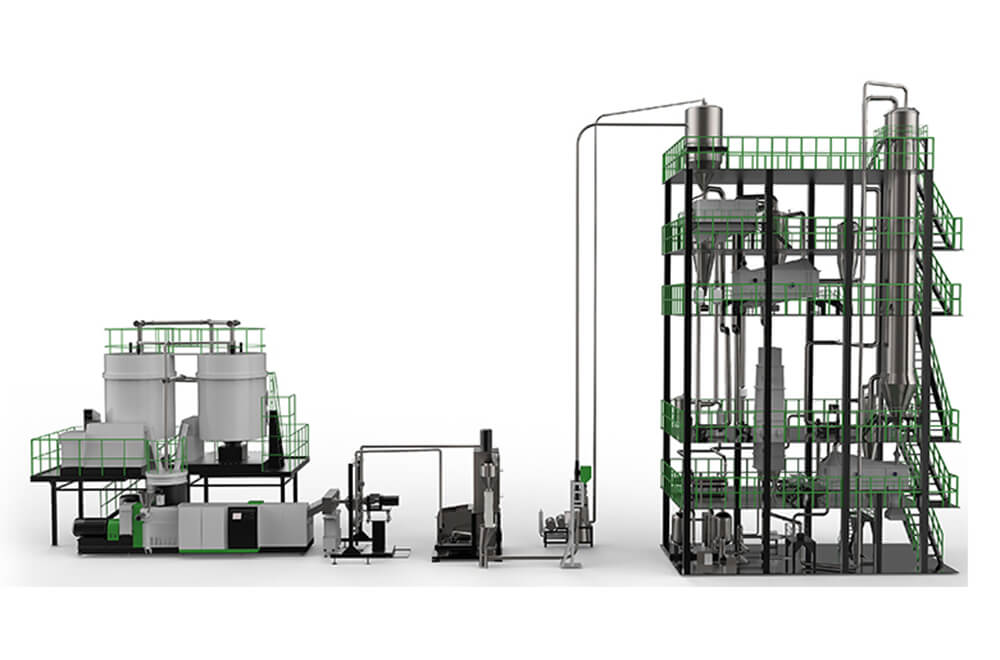

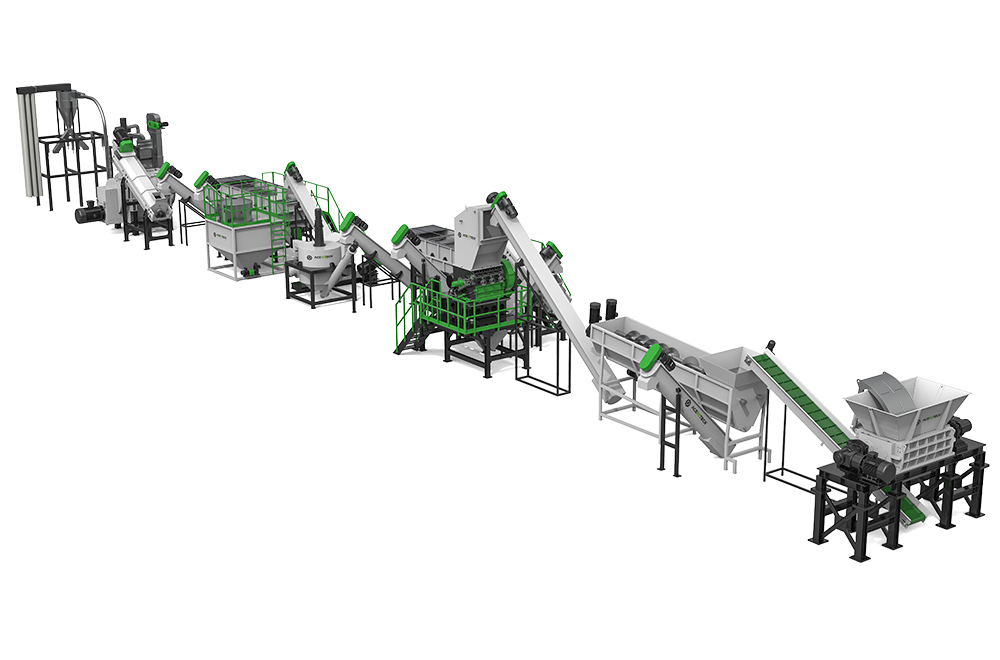

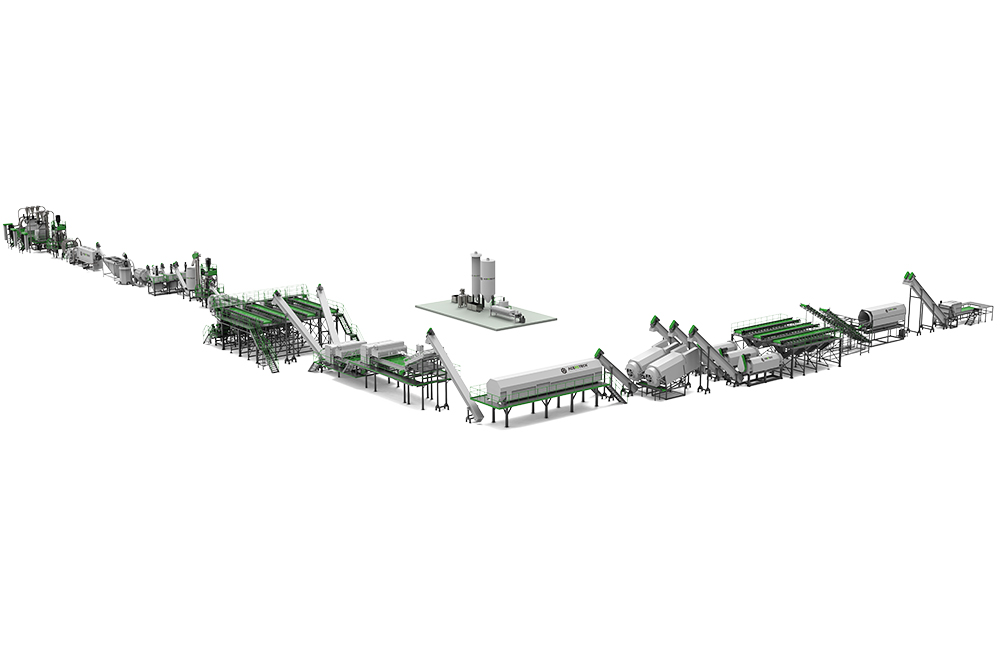

.jpg) Washing And Pelletizing Turn-key Solution

Washing And Pelletizing Turn-key Solution -

.jpg) Water Treatment System

Water Treatment System -

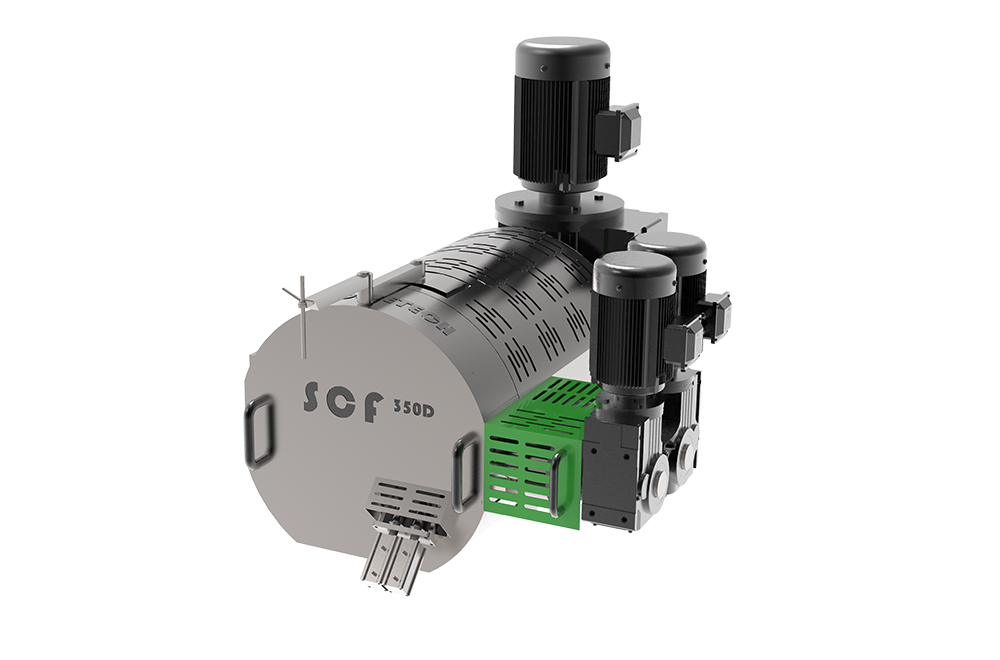

Plastic Pulverizer Machine

Plastic Pulverizer Machine -

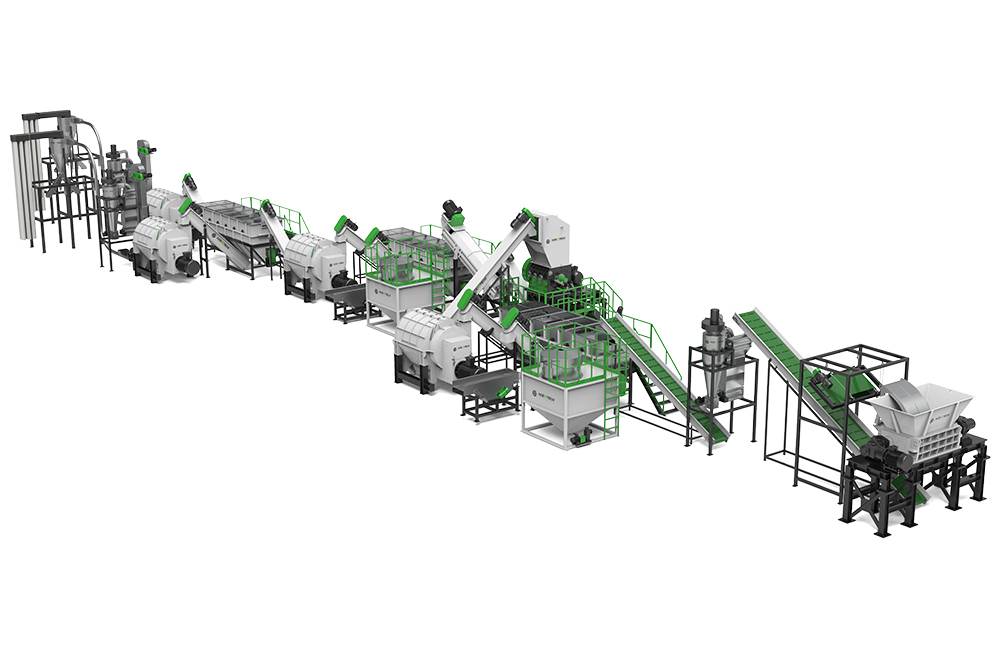

PET Recycling Line

PET Recycling Line -

Auxiliary Machine For Plastic Recycling

Auxiliary Machine For Plastic Recycling

-

- Cutter Compactor Recycling Pelletizing System

- Single Screw Extruder Recycling Pelletizing System

- Twin Screw Extruder Compounding & Recycling

- Shredder Extruder Recycling Pelletizing System

- Crusher & Shredder

-

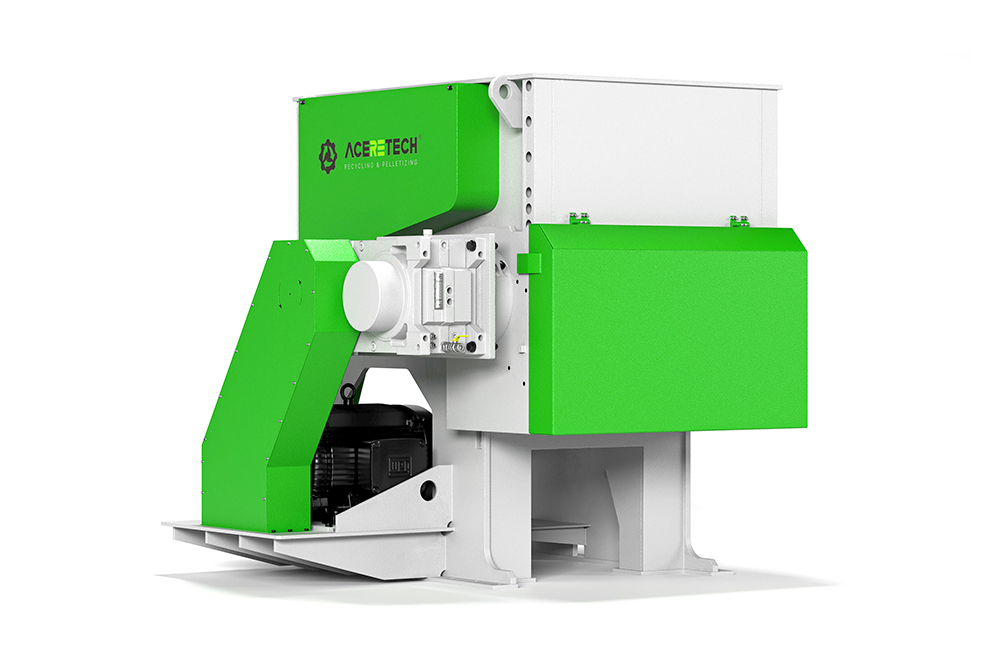

HS Series Single Shaft Hard Plastic Shredder

HS Series Single Shaft Hard Plastic Shredder -

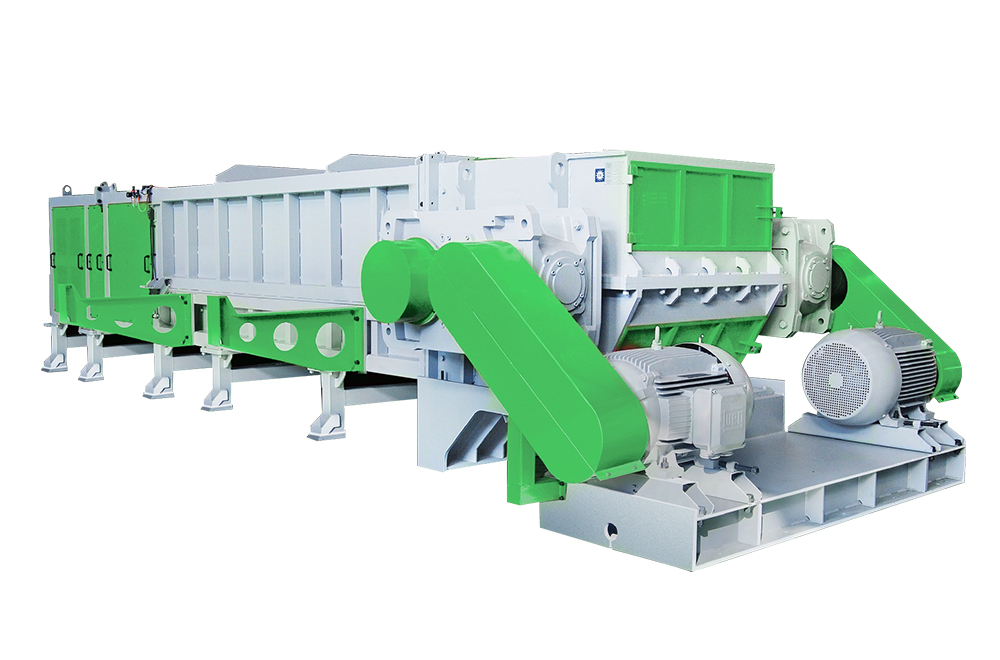

XS Series Carbon Steel Industrial Multifunctional Plastic Shredder With Siemens Plc

XS Series Carbon Steel Industrial Multifunctional Plastic Shredder With Siemens Plc -

MS Series Adjustable PP PVC PE HDPE Pipe Waste Industail Plastic Shredder

MS Series Adjustable PP PVC PE HDPE Pipe Waste Industail Plastic Shredder -

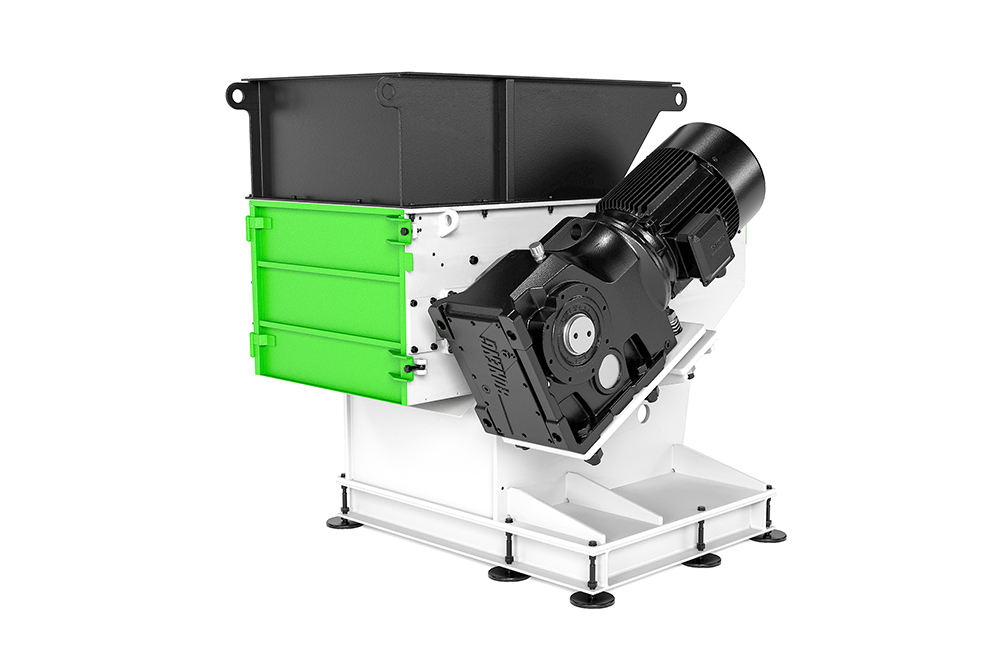

LS Series Plastic Waste Single Shaft Shredder With Small Volume And Wall Thickness

LS Series Plastic Waste Single Shaft Shredder With Small Volume And Wall Thickness -

PS Series Single Shaft Plastic Shredder For Pipe Recycling

PS Series Single Shaft Plastic Shredder For Pipe Recycling -

GP Series Plastic Crusher Machine For Grinding Long Plastic Pipes

GP Series Plastic Crusher Machine For Grinding Long Plastic Pipes -

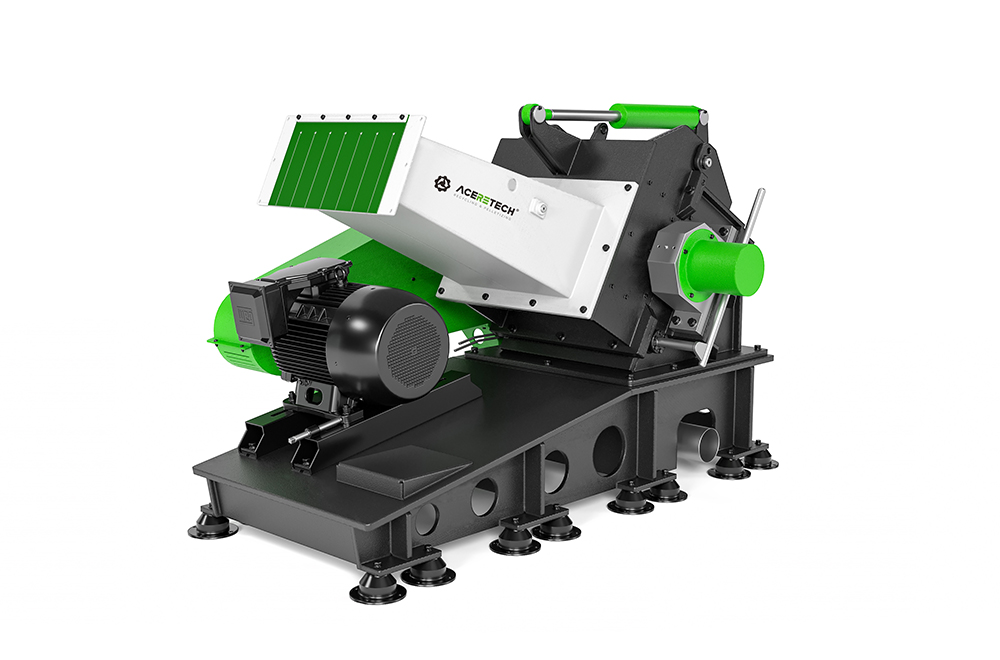

GH Heavy-Duty Plastic Crushers Grinding Machine

GH Heavy-Duty Plastic Crushers Grinding Machine -

GF Series High Output Efficient Plastic Crusher Machine

GF Series High Output Efficient Plastic Crusher Machine -

GE Plastic Recycling Shredder Machine For Waste Management

GE Plastic Recycling Shredder Machine For Waste Management

-

- Washing And Pelletizing Turn-key Solution

- Water Treatment System

- Plastic Pulverizer Machine

- PET Recycling Line

-

R-PET Food Grade Sheet Extrusion Line

R-PET Food Grade Sheet Extrusion Line -

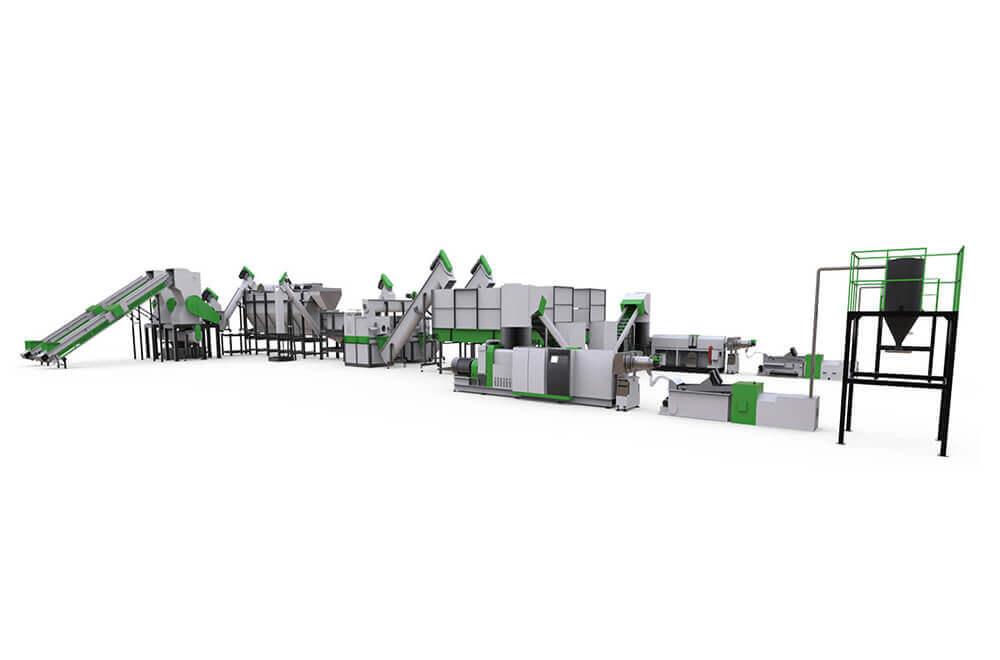

APET Plastic PET Bottles Washing and Pelletizing Recycling line

APET Plastic PET Bottles Washing and Pelletizing Recycling line -

AWS-PET PET Bottle Recycling Washing Line

AWS-PET PET Bottle Recycling Washing Line -

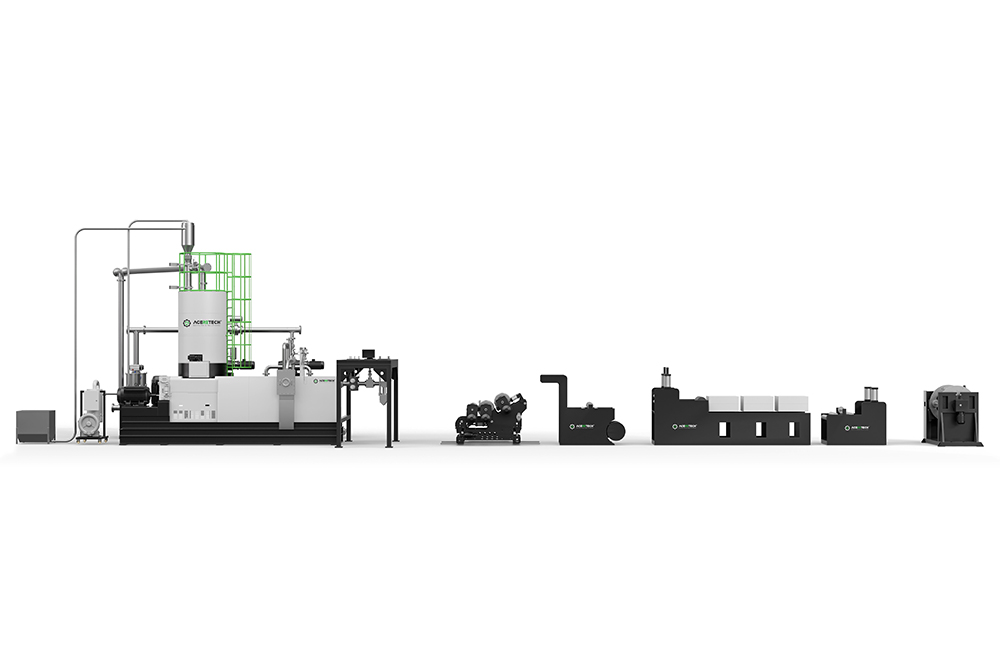

SSP (Continuity) Pet Waste Recycled Plastic Pelletizing Machine For IV Increase

SSP (Continuity) Pet Waste Recycled Plastic Pelletizing Machine For IV Increase -

LSP Pet Plastic Recycling Machine Line With Liquid State Polymerization System For IV Improvement

LSP Pet Plastic Recycling Machine Line With Liquid State Polymerization System For IV Improvement

-

- Auxiliary Machine For Plastic Recycling

-

Products list

- Application

- E-CATALOG

- Video

- Contact Us

Products

-

T +86-512-58622021

-

F +86-512-58622021

18# Yuefeng road, Nanfeng town, Zhangjiagang city. Jiangsu province, China

Su ICP Bei 15032987 Hao -1

Su ICP Bei 15032987 Hao -1

© ACERETECH Machinery Co.,Ltd | Privacy Policy |

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us