PM500 PVC Pulverizer Machine for Plastic Recycling

The pulverizer is suitable for the pulverization of semi-rigid, brittle and impact resistant materials that require powdered products.

Particles with a size of 6-8 mm are fed through a vibrating screen into a rotating high-speed sawtooth disc to produce a powder product in the desired 300-1000 micron range, with the final size determined by adjustable disc spacing. Typically used for shredding LDPE, HDPE, UPVC, PC and various other plastics.

Recycling & Material

Advantages

01. Low maintenance cost

The equipment has a simple structure, few wearing parts, easy maintenance, and reduced maintenance costs.

02. Wide range

It can process a variety of plastic materials to meet the needs of different customers.

03. High grinding precision

The powder is fine and uniform, improving product quality and meeting the needs of the high-end market.

04. Safe and reliable

The fully enclosed design prevents dust leakage and ensures production safety.

05. Automation Equipment

Automatic loading, grinding, and discharging are realized, reducing manual intervention.

06. Small footprint

The compact design saves workshop space and reduces plant investment.

Specifications

|

Model

|

PM500

| ||

|

Raw material

|

H-PVC-Profile ,H-PVC-Pine ,LDPE(MFI70) and etc.

|

Final product & capacity

|

250~500kg/h, depends on condition of client's material.

|

|

Electric current

|

3×380V, 50Hz; control current 220V, 50Hz

|

Rotor speed

|

5250 rmp

|

|

PE

|

250-300 kg/h

|

Disc diameter

|

500 mm

|

|

Profile- H-PVC

|

400-500kg/h

|

Tooth grooves

|

2.62 |

|

Pipe- H-PVC

|

450-600 kg/h

|

Drive motor

|

55 kw

|

PM500 PVC Pulverizer Machine for Plastic Recycling

Applications

The pulverizer is suitable for the pulverization of semi-rigid, brittle and impact resistant materials that require powdered products.

Particles with a size of 6-8 mm are fed through a vibrating screen into a rotating high-speed sawtooth disc to produce a powder product in the desired 300-1000 micron range, with the final size determined by adjustable disc spacing. Typically used for shredding LDPE, HDPE, UPVC, PC and various other plastics.

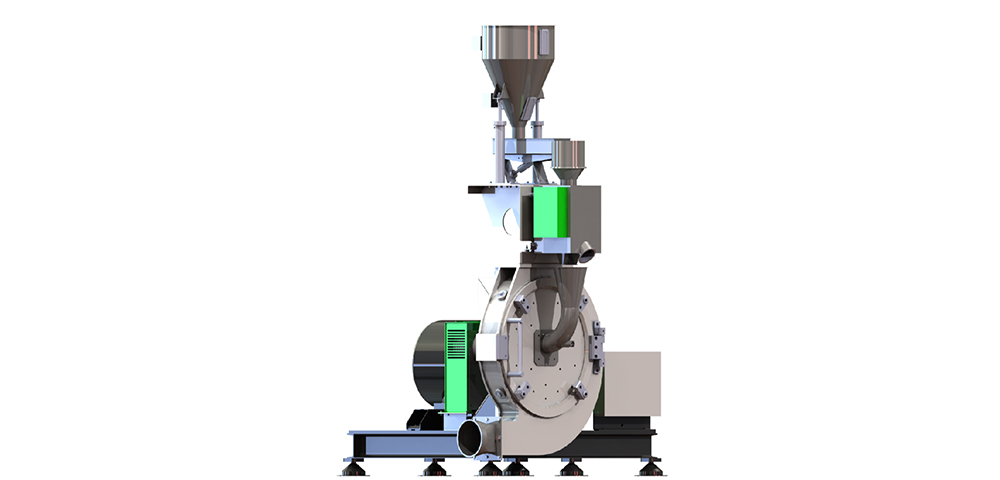

Design

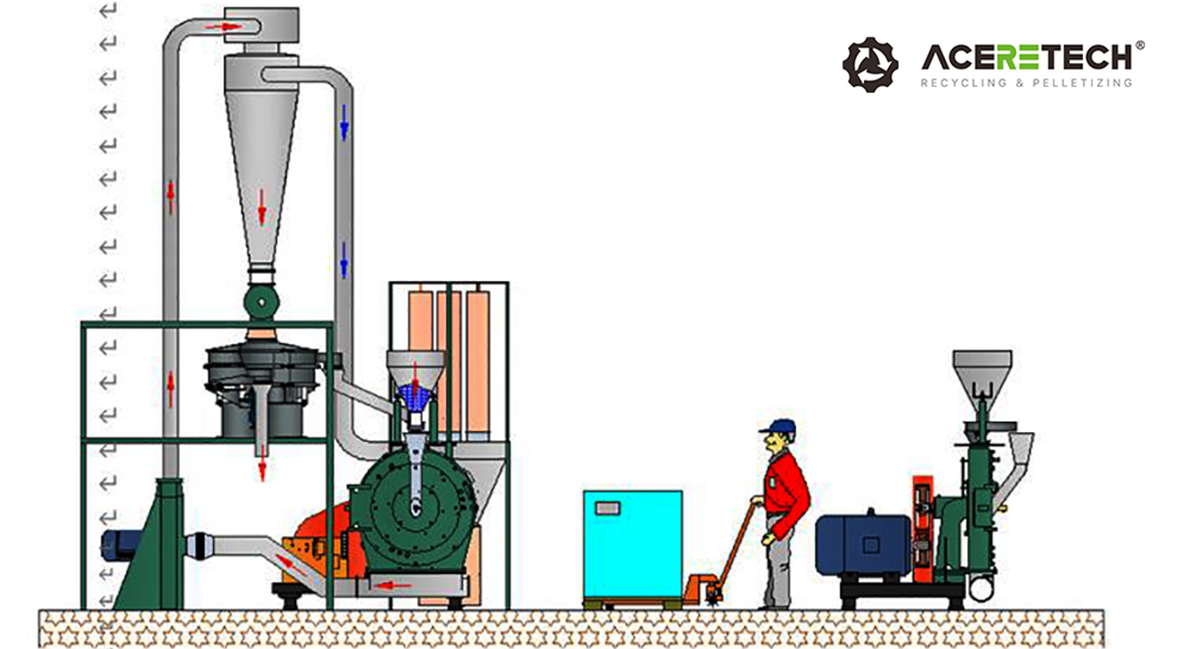

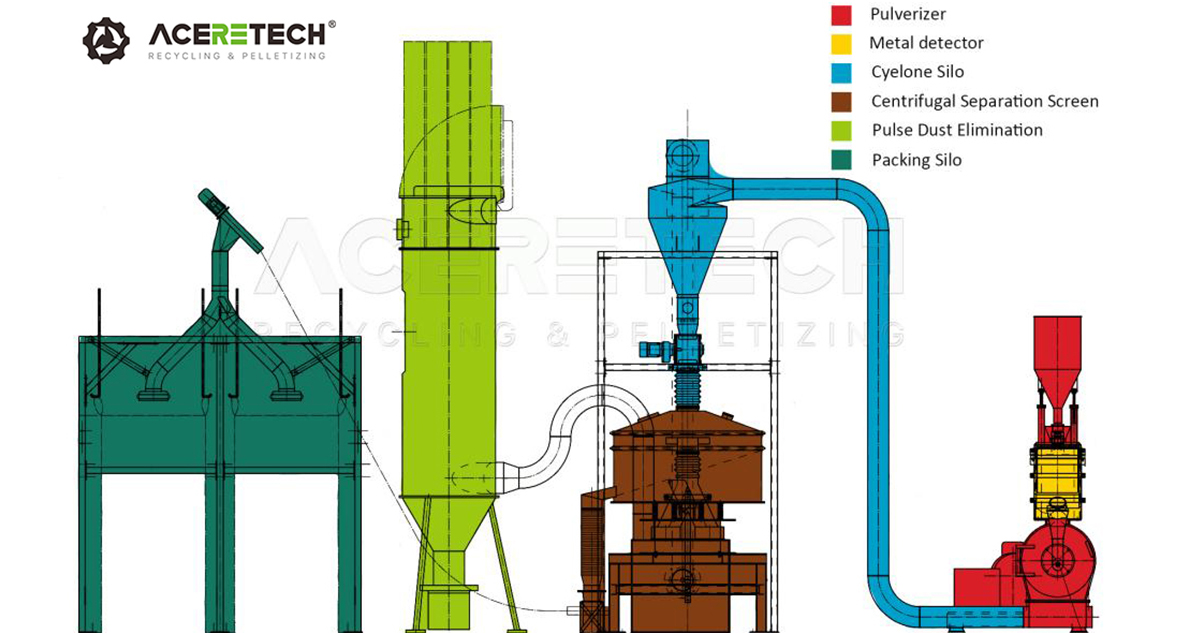

The PM500 pulverizer series are ultra-high output units that can be equipped with automatic temperature control. The material to be pulverized is fed centrally between fixed and high-speed rotating pulverizing discs, which have a centrifugal effect, allowing the material to pass through the processing zone and then be pneumatically discharged from the machine.

Advantages

* Long service life of discs between regrindings.

* Replace and adjust discs quickly and easily.

* Low residence time means low thermal stress on the process material.

* High throughput capabilities.

* Cost effective operation.

Technical features

* Dosing channel/Vibratory feeder

* The channel width is 100 - 250mm, and the storage container is appr. 50-100 lit.

* The feeding is regulated and consumed by the high current controller monitoring the pulverizer motor, including the mounting bracket and control device.

Pulverizer housing

* Disc pulverizer with a fixed and a high-speed toothed disc with precision bearings.

* Material is fed through the opening in the center of the fixed disc.

* The size of the particles depends on the surface structure of the teeth and the adjustable distance between the tooth discs. The cutting clearance can be checked through the inspection hole in the housing. This makes it easy to adjust from the outside of the device using a feeler gauge. The device operates without a screen.

* The machine housing is made of fracture resistant welded steel. The hinged housing door with fixed toothed disc opens to the side for cleaning and replacing the toothed disc.

* The grinding chamber is well designed with a small cross-section and a flat, almost vertically mounted grinding disc.

* The material is clamped and reduced immediately after entering the grinding chamber.

Pulverizer discs

* Specially designed discs and high-speed peripheral running speed ensure efficient impact reduction under low power requirements.

* Pulverizer disc diameter 800mm

Temperature control

The enhanced cooling device for automatically controlling the temperature includes a nozzle for spraying in cooling water, regulating control devices, solenoid valves, thermostats, an automatic control device and a material feeding switch.

Drive and mounting frame

A flat steel structure is used to install the pulverizer and suction box. The drive motor includes "V" belt drive and belt guard. The frame is equipped with pre installed anti vibration pads.

Safety devices

Integrated operational safety device to prevent entry until the rotor is completely stationary.

Pulverizer machine