Recycling PET bottles is not only about reducing waste; it is about transforming discarded materials into valuable resources. PET, or polyethylene terephthalate, is one of the most common plastics used for beverage bottles and food packaging. Its popularity brings convenience, but also creates a significant environmental burden. PET bottle flakes recycling and pelletizing provide a practical solution, enabling these materials to return to the production cycle instead of ending up in landfills.

From Bottle to Flake: The First Transformation

The process starts with post-consumer PET bottles, which are collected, sorted, and stripped of labels and caps. Once prepared, they are crushed into small, uniform PET flakes. These flakes become the essential feedstock for creating high-quality recycled PET pellets.

Key steps in flake preparation:

- Sorting to remove contaminants

- Washing to remove labels, adhesives, and food residue

- Crushing into uniform flakes for consistent downstream processing

Deep Cleaning and Drying: Preparing for Pelletizing

Before pelletizing can begin, the PET flakes must be thoroughly cleaned and dried. Multiple washing stages—pre-wash, hot caustic wash, and fine filtration—are followed by crystallization drying. The crystallization drying equipment effectively removes moisture, ensuring the flakes are dry enough for stable extrusion. This step lays a solid foundation for consistent pellet quality.

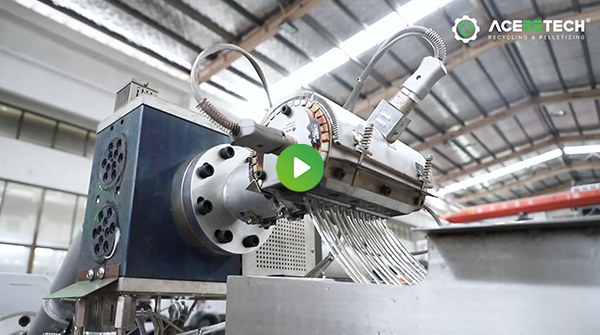

Pelletizing with the Aceretech ASE Single Screw Pelletizer

At the heart of the process is the Aceretech ASE single screw pelletizer, a system engineered for efficient and stable PET flake processing. Its design combines automation, precision, and continuous production capability.

Core features include:

- Spiral conveying and feeding – Automatic, uniform material transport that boosts production efficiency and ensures stable downstream processing.

- Crystallization drying equipment – Removes moisture from flakes to improve dryness and readiness for extrusion.

- Lamp tube design – A unique structure that allows operators to visually monitor material conditions in real time for consistent quality.

- Single screw extrusion – Ensures PET flakes are fully melted under high temperature and pressure to form a uniform melt.

- Double vacuum degassing – Removes gases and impurities, improving the transparency and cleanliness of the final pellets.

- Remote intelligent control system – Enables remote monitoring and operation, making production management more convenient and intelligent.

- Non-stop piston filter – Maintains continuous production while filtering impurities, ensuring both efficiency and product purity.

- Underwater pelletizing – Produces uniform, oxidation-free pellets with a smooth finish.

- Vibrating screen – Removes unqualified particles to maintain uniformity and high quality.

- Air conveying silo – Automates pellet transport to reduce manual handling and improve efficiency.

Restoring Material Quality with SSP and LSP

Even high-quality recycled PET can lose intrinsic viscosity over time, which affects its performance. Technologies like Solid-State Polymerization (SSP) and Liquid-State Polycondensation (LSP) restore this property, enabling the recycled PET to match the strength, clarity, and processing characteristics of virgin PET.

Benefits of viscosity restoration:

- Meets strict food-grade packaging standards

- Enhances strength for textile and industrial applications

- Extends the lifecycle of recycled materials

Looking Ahead: Why This Matters

PET bottle flakes recycling and pelletizing play a crucial role in building a circular economy. By converting waste into new raw materials, manufacturers reduce their reliance on virgin plastics, cut carbon emissions, and keep valuable resources in use longer.

With innovations like the Aceretech ASE single screw pelletizer, combined with advanced sorting, drying, and pelletizing technologies, PET recycling is becoming more efficient, sustainable, and ready to meet the demands of the future.

Aceretech offers comprehensive plastic waste recycling solutions tailored to your specific needs. Contact our team today to discuss how we can help you achieve your recycling and sustainability goals.

Topic: PET Bottle Recycling