In the field of plastic recycling equipment manufacturing, processing accuracy and surface finish directly determine the durability and efficiency of the equipment. As an industry-leading plastic recycling machine manufacturer, ACERETECH's workshop is equipped with multiple high-precision large-scale CNC equipment to ensure that key components meet the precision processing standards of 0.01-0.05mm. The following is a detailed analysis of the core equipment:

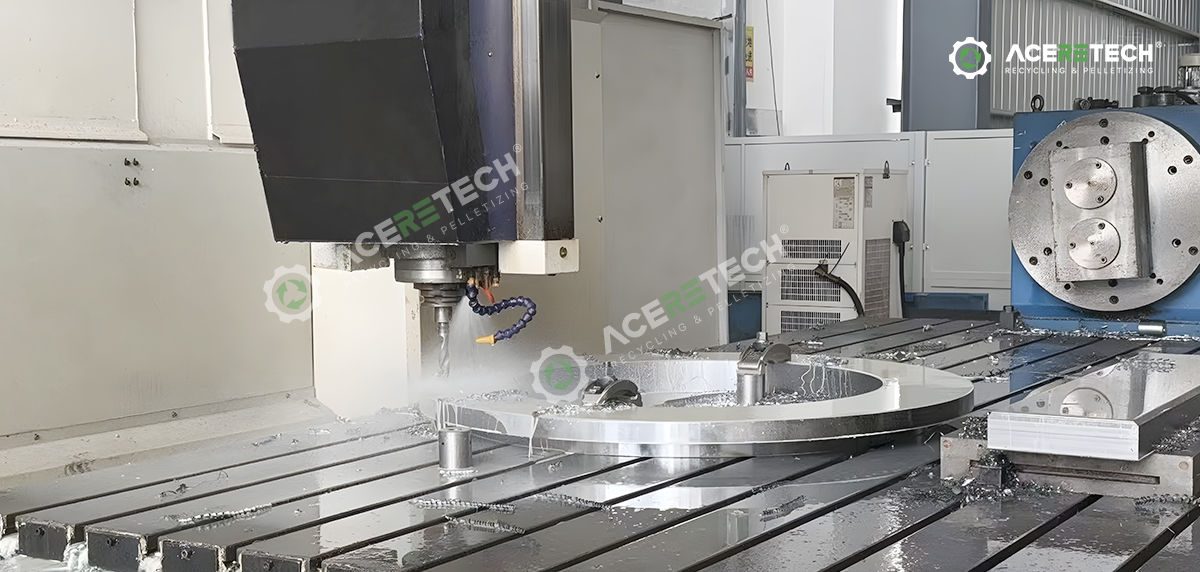

Gantry milling machine 2213: the core of precision machining of large-size parts

Model: Gantry milling machine 2213

Processing capacity: 2000mm (length) × 1300mm (width) × 1000mm (height)

Processing accuracy: 0.01-0.05mm

Spindle system: BBT50 high-rigidity spindle, suitable for heavy cutting and high-precision milling

Core processing parts:

Shredder side plate, end plate and rotor

Crusher side plate, screw loader end plate

Frame bearing seat, bearing sleeve and other large structural parts

Technical advantages:

The equipment achieves stable machining of large-span workpieces through a high dynamic response servo system, ensuring that the surface of parts with strict dynamic balance requirements such as shredder rotors is smooth and free of vibration marks.

CNC surface grinder: high finish precision surface processing

Processing capacity: 1200mm×500mm

Processing accuracy: 0.01-0.05mm

Core processing parts:

Blades (friction washers), flanges, molds

Connectors, cylinder brackets and other high-precision flat parts

Technical highlights:

Adopting diamond grinding wheel precision dressing technology, the surface roughness can reach within Ra0.4μm, especially suitable for mirror processing of hydraulic system components (such as flanges) and molds that need to fit closely.

Gantry milling machine 4280: integrated processing solution for super-large workpieces

Model: gantry milling machine 4280

Processing capacity: 4000mm (length) × 2000mm (width) × 1100mm (height)

Processing accuracy: 0.01-0.05mm

Spindle system: BT50 spindle, taking into account both high-speed cutting and heavy-load capacity

Core processing parts:

Pulverizer rotor, large-area screen changer

SCF laser filter frame, crusher side plate

Screw loader end plate and heavy-duty frame

Industry application:

For the overall milling of super-large welded parts in plastic recycling equipment, multi-faceted processing is completed in one clamping, reducing cumulative errors and ensuring that the coaxiality of the hole system of key parts such as bearing seats is ≤0.02mm.

ACERETECH's manufacturing philosophy: balance between precision and efficiency

Through the above equipment combination, ACERETECH has achieved full coverage of processing from small precision parts to ultra-large structural parts. Its advantages are reflected in:

Process chain closed loop: seamless connection between milling and grinding processes to avoid secondary clamping errors.

Surface treatment optimization: high finish reduces friction loss of parts and extends equipment life.

Customization capability: dynamic balancing correction services are provided for complex parts such as shredder rotors.

Conclusion: As the plastic recycling industry develops towards efficiency and refinement, ACERETECH, with its high-precision processing equipment cluster, continues to provide customers with core components of recycling equipment with excellent performance and strong stability, becoming an important promoter of global plastic recycling technology.

High-Precision Manufacturing Model: Analysis Of The Core Processing Equipment Of ACERETECH Plastic Recycling Machine Manufacturer

2025/04/10

in Company News