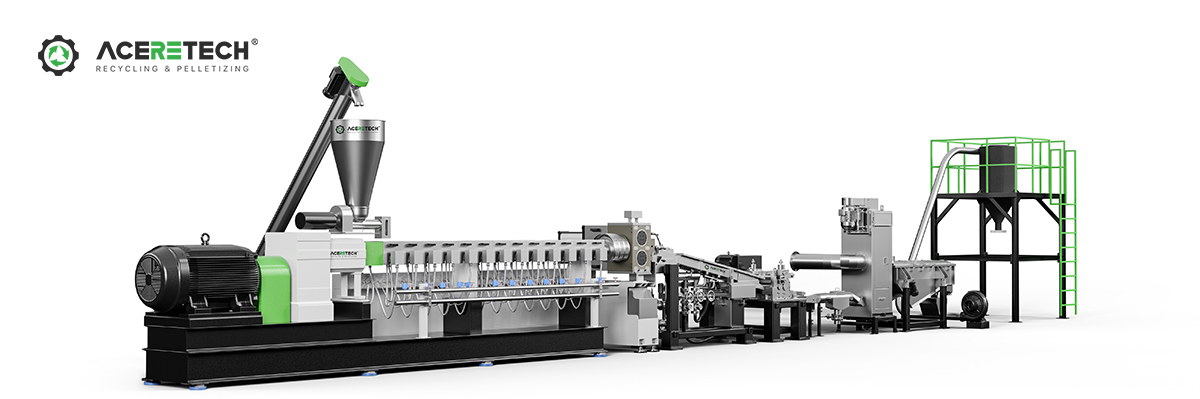

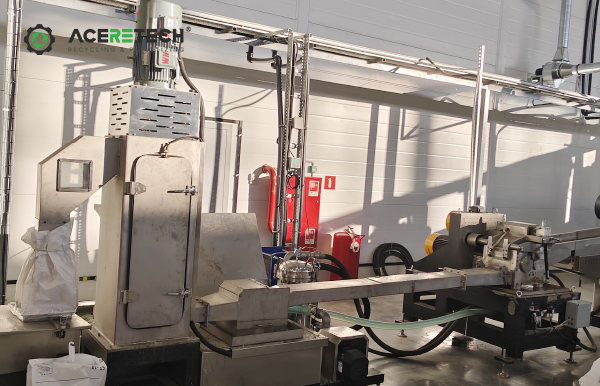

Recently, the PET bottle flakes recycling and pelletizing line independently developed by ACERETECH has been successfully installed and debugged at the Russian customer's site, which has been officially put into production.

This production line adopts internationally leading process technology and automatic control system, with core configurations including:

Drying system for PET flakes:

Efficiently remove moisture from PET bottle flakes, avoid hydrolysis, and provide high-quality raw materials for subsequent processing

Twin screw extruder:

Unique screw element design and temperature control system effectively reduce energy consumption and improve production efficiency

Filtration and vacuum degassing system:

Precision filtration and devolatilization system effectively removes impurities and moisture, ensuring stable quality of regenerated pellets. lt can be widely used in fields such as fiber and packaging field

Automatic strands pelletizing system:

Easy to operate, making the pellets more uniform, the appearance of the pellets smooth, stable quality ,and meet the needs of high-end applications

Crystallization system:

Effectively improves the crystallinity and heat resistance of recycled PET pelletsexpanding application range

The entire line adopts environmentally friendly design, with low noise and less dust, helping customers achieve their green production goals.

This successful is another achievement of ACERETECH's deep cultivation in the PET recycling field and its commitment to technological innovation. lt also provides strong support for Russian customers to develop a circular economy and achieve sustainable development!