In the field of plastic recycling, we frequently discuss water-based washing lines. For many clients, water consumption is significant. Therefore, in addition to washing projects, we also design customized water treatment systems for our clients' washing equipment to optimize their water usage. With our extensive knowledge and experience, we aim to provide turnkey projects and/or consulting services to all our clients.

Different plastics, whether rigid recycled materials (HDPE, PP bottles, cartons, PET bottles, etc.) or flexible recycled materials (PP raffia, PE film, etc.), require different amounts of water per hour (tons/cubic meters), in addition to varying production rates of the mechanical washing lines (kg/hour).

For example, a PET bottle washing plant with a capacity of 1000 kg/hour requires 10 tons of water per hour, while a PE film washing plant with the same capacity requires 20 tons of water per hour.

Therefore, to develop a customized solution, we need data on the materials to be washed and relevant data on your existing washing production line. With this information, our technicians can design the required water treatment system.

We recently installed a wastewater treatment plant (WWTP) for a client in Argentina with a treatment capacity of 30 tons per hour. After adjustments by our on-site technicians, the final treatment capacity reached 38 tons per hour, significantly reducing water consumption for the client's two production lines: one for washing post-consumer HDPE bottles and the other for washing PP raffia.

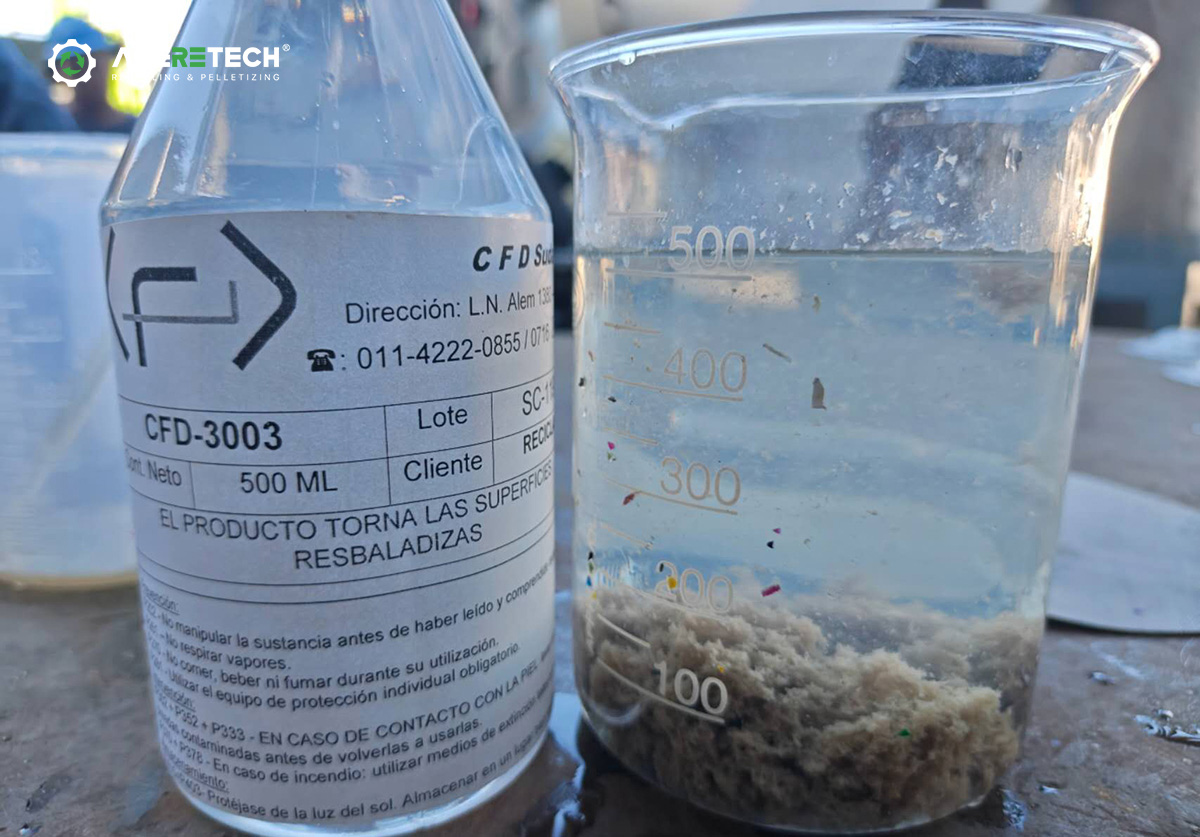

Water treatment for washing lines is primarily based on flocculation theory. We utilize our understanding of the plastics being washed and their chemical formulations to design the optimal flocculant ratio.

With this wastewater treatment plant, we can clean the plastics more thoroughly, ultimately resulting in higher quality plastic granules. Of course, we also conserve freshwater resources. This greatly benefits the circular economy.