I. Main types of global waste plastic classification

Global waste plastics can be mainly divided into the following categories:

1. PET (polyethylene terephthalate): mainly used for beverage bottles, food packaging, etc.

2. HDPE (high-density polyethylene): used for milk bottles, shampoo bottles, detergent containers, etc.

3. PVC (polyvinyl chloride): pipes, window frames, credit cards, etc.

4. LDPE (low-density polyethylene): plastic bags, packaging films, etc.

5. PP (polypropylene): microwave lunch boxes, straws, bottle caps, etc.

6. PS (polystyrene): foam packaging, disposable tableware, etc.

7. Other plastics: including plastics that are difficult to classify, such as multi-layer composite materials

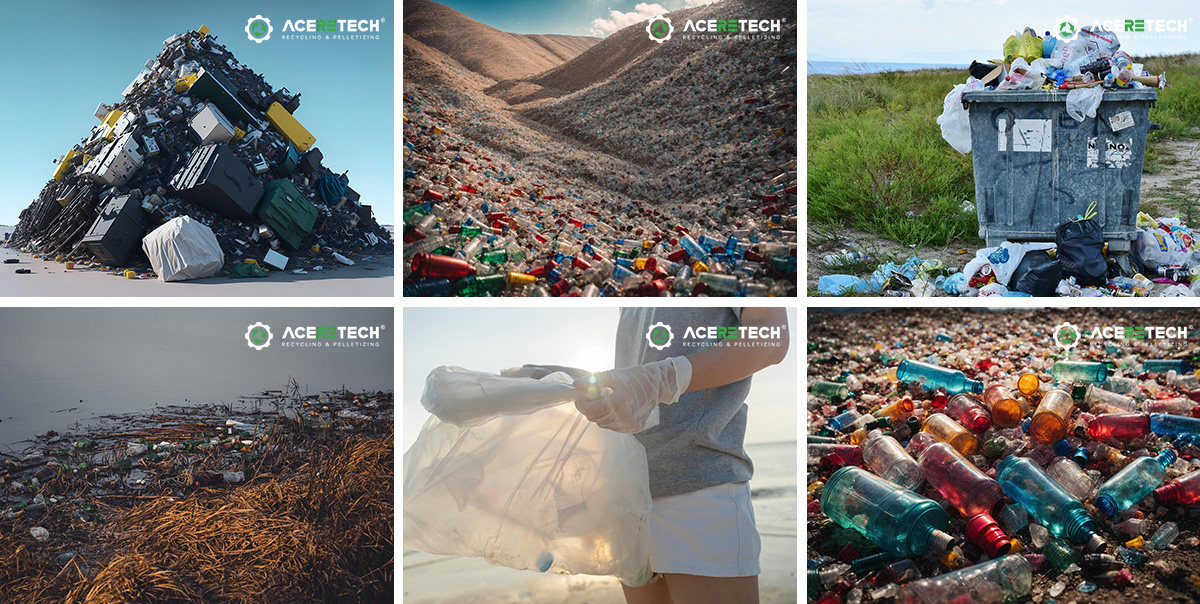

II. The severity of global waste plastic pollution

Plastic pollution has become a global environmental crisis. According to statistics:

- About 400 million tons of plastic waste are generated worldwide each year

- Only 9% of plastic waste is recycled, 12% is incinerated, and 79% ends up in landfills or the natural environment

- About 8 million tons of plastic enter the ocean each year, which is equivalent to dumping a garbage truck of plastic into the sea every minute

- It takes 400-1000 years for plastic to degrade in the natural environment, and microplastics have entered the human food chain

- Plastic pollution causes the death of more than 1 million marine organisms each year

III. Current status of global waste plastic recycling

Currently, global waste plastic recycling presents the following characteristics:

1. Large regional differences: The recycling rate in the EU is about 30%, the United States is less than 9%, and many developing countries lack effective recycling systems

2. Technical bottlenecks: It is difficult to recycle multi-layer composite plastics and heavily polluted plastics

3. Economic factors: Fluctuations in the price of virgin plastics affect the economic feasibility of recycling

4. Policy promotion: More and more countries are implementing the extended producer responsibility system (EPR) and plastic bans

5. Innovation trends: development of chemical recycling technology, application of digital traceability system

IV. Economic value of waste plastic recycling

Waste plastic recycling has significant economic benefits:

1. Raw material saving: recycling 1 ton of plastic can save about 1.5 tons of crude oil

2. Energy saving: the energy consumption of recycled plastic production is only 10-30% of that of virgin plastic

3. Job creation: The global waste plastic recycling industry has created millions of jobs

4. Market value: The global recycled plastic market size is expected to reach US$72 billion in 2027

5. Industrial chain value: driving the development of the entire industrial chain of recycling, sorting, processing and manufacturing

V. Detailed explanation of the main equipment for waste plastic recycling

1. Plastic shredder

Working principle:

Plastic shredder uses shear force to tear large plastic products (such as plastic barrels, furniture, pipes, etc.) into smaller pieces through two relatively rotating knife shafts. The knife shaft usually has a slow speed but a large torque, which can handle heavy plastic products.

Features:

- Large processing capacity, suitable for initial volume reduction

- Wear-resistant blade material, replaceable

- Blade gap and speed can be adjusted according to different plastic types

Applicable plastics: HDPE, PVC, PP and other hard plastics

2. Plastic crusher

Working principle:

Plastic crusher breaks plastic into smaller particles by impacting and cutting it with high-speed rotating blades. Compared with shredders, crushers have higher speeds and smaller output particle sizes.

Type:

- Single-shaft crusher: single rotating blade with fixed blade

- Double-shaft crusher: two shafts rotate relative to each other, better shearing effect

Features:

- Adjustable discharge size (usually 5-20mm)

- Equipped with screen to control particle size

- Some models have noise reduction design

Applicable plastics: all kinds of plastics, especially suitable for thin-walled products and films

3. Plastic washing line

Working principle:

Plastic washing line is a system that removes labels, glue, residues and pollutants from plastic fragments through multiple processes, usually including:

1. Pre-washing: remove loose attachments

2. Hot washing: use hot water and detergent to remove grease and stubborn stains

3. Friction washing: further cleaning through mechanical friction

4. Rinse: rinse with clean water

5. Dehydration: centrifugal dehydration or extrusion dehydration

Key equipment:

- Sinking and floating separation tank: use density differences to separate different plastics

- Friction cleaning machine

- High-speed dehydrator

Features:

- Water resource recycling system

- Can handle plastics with different pollution levels

- High degree of automation

4. Wastewater treatment system

Working principle:

The wastewater generated during the plastic cleaning process undergoes multi-stage treatment:

1. Sedimentation tank: remove large suspended particles

2. Flotation device: remove grease and fine particles

3. Biological treatment: degrade organic pollutants

4. Membrane filtration: deep treatment

5. Sludge treatment: dehydration and drying

Features:

- Realize water resource recycling

- Meet environmental emission standards

- Sludge can be treated as solid waste or further utilized

5. Plastic granulator

Working principle:

The granulator converts clean and dry plastic fragments into uniform plastic particles through heating, melting, filtering, extrusion and granulation. Main steps:

1. Feeding: Plastic fragments enter the extruder barrel

2. Melting: Melting the plastic through electric heating and screw extrusion

3. Filtration: The melt passes through a porous filter to remove impurities

4. Extrusion: Forming strips through the die head

5. Cooling: Water cooling or air cooling

6. Pelletizing: Rotating knives cut the plastic strips into uniform pellets

Types:

- Single screw pelletizer: Simple structure, suitable for ordinary plastics

- Twin screw pelletizer: Good mixing effect, suitable for complex formulas

Features:

- Masterbatch or modifier can be added

- Accurate temperature control system

- Output ranges from tens of kilograms to several tons/hour

6. Plastic extruder

Working principle:

Plastic extruder heats and plasticizes plastic pellets or powders through a screw, and then continuously extrudes them through a specific mold. Main components:

1. Feeding system: precise control of raw material input

2. Extrusion system: plasticizing device composed of screw and barrel

3. Heating and cooling system: precise control of temperature in each zone

4. Mold: determines the cross-sectional shape of the product

5. Traction and cutting system: controls product size

Application:

- Production of plastic pipes, profiles, plates, films, etc.

- Recycled plastic particles can be used directly

Features:

- Can be equipped with a variety of molds to produce different products

- High degree of automation

- Energy-saving design, high thermal efficiency

With stricter environmental regulations and technological advances, the waste plastic recycling industry is moving towards a more efficient, cleaner and higher value-added direction. A complete recycling equipment system and a mature recycling industry chain will provide important support for solving the global plastic pollution problem.

Global Waste Plastic Recycling Equipment and Technology: Full Process Analysis from Recycling to Reuse

2025/05/29