As a crucial piece of equipment in the plastic recycling industry, the stable operation of a plastic shredder is crucial to the entire recycling process. However, the lifespan of equipment is not fixed. Effective maintenance can effectively extend the lifespan of a plastic shredder, reduce malfunctions, and improve efficiency. Below are some tips for maintaining a plastic shredder.

Regular Cleaning to Keep It Clean

During operation, plastic shredders continuously process various plastic materials, which may contain dust and impurities. If not cleaned promptly, these impurities will accumulate inside the machine, affecting heat dissipation and operation. Therefore, regular cleaning is the first step in maintenance. After each cycle, use a soft brush or compressed air to clean plastic debris and dust from the machine's surface. Clean the interior of the machine periodically by disassembling some components and wiping the blades, frame, and other areas with a clean cloth. Pay special attention to removing plastic residue from the blades, as long-term plastic accumulation can affect cutting performance and even damage them.

Lubrication and Maintenance Ensure Flexible Joints

When a plastic shredder is in operation, various components, such as bearings and gears, move relative to each other. Lack of lubrication in these parts will cause friction, accelerating component wear and shortening the equipment's lifespan. Therefore, regular lubrication and maintenance are essential. Generally, an appropriate amount of lubricant or grease should be added to bearings, gears, and other components at regular intervals (e.g., every 100 hours). When adding lubricant, ensure that the lubrication system is functioning properly, such as checking for blockages or leaks in the lubricant lines.

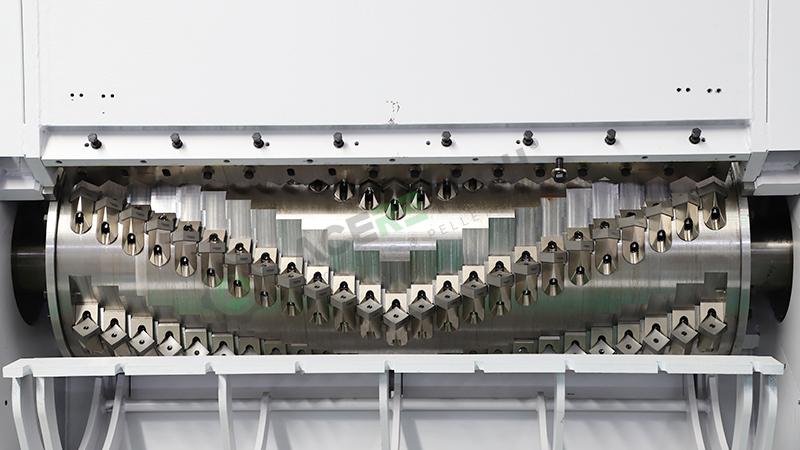

Blade Maintenance Ensures Sharpness

The blade is the core component of the plastic shredder, and its sharpness directly affects the shredding performance. Therefore, proper blade maintenance is crucial. During daily use, monitor the blade for wear. If the blade becomes dull, sharpen it promptly. Use specialized sharpening equipment to ensure a smooth, sharp edge. Additionally, regularly check that the blade is securely installed. If the blade is loose, tighten it immediately. Severely worn blades should be replaced promptly to prevent blade problems from affecting the normal operation of the equipment.

Electrical System Inspection: Ensure a Healthy "Heart"

The electrical system of a plastic shredder is the "heart" of the equipment. Its proper operation is crucial to the startup, operation, and shutdown of the entire machine. Therefore, regular inspections of the electrical system are essential. Check for aging or damage to wires, loose plugs, and proper functioning of electrical components. If a wire is found to be aging or damaged, replace it immediately; if a plug is loose, tighten it immediately; if an electrical component is faulty, repair or replace it promptly. Additionally, regularly clean dust from the electrical box to prevent it from affecting its proper function.

Operation Monitoring: Detect Problems Early

During daily use, always monitor the operating status of the plastic shredder. Observe parameters such as noise, vibration, and temperature to ensure they are normal. If abnormal noise, excessive vibration, or excessive temperature are detected, stop the machine immediately for inspection to identify and resolve the cause. Do not continue to operate the machine in an abnormal state to avoid further damage.

Seasonal Maintenance to Adapt to Different Environments

Plastic shredders require appropriate maintenance depending on the season and environmental changes. During humid seasons, ensure the equipment is moisture-proof. Place desiccant around the equipment to protect the electrical components from moisture. During cold seasons, ensure the equipment is frost-proof. If the equipment is not used for an extended period, drain the water inside to prevent the pipes from freezing and cracking. Additionally, seasonal adjustments can be made to the equipment's operating parameters based on the characteristics of the plastic material to achieve optimal shredding results.

By following these maintenance tips, we can effectively extend the life of our plastic shredder, improve its efficiency, and reduce maintenance costs. This will ensure that the plastic shredder continues to play its powerful role in plastic recycling and contribute significantly to environmental protection.

If you have any questions about shredder maintenance or other issues related to plastic recycling machines, please contact Aceretech Machinery!

Request a Quote!