What is a plastic shredder?

A plastic shredder is an industrial equipment specially used to process various plastic materials. It can tear large plastic products, plastic scraps, waste plastics, etc. into smaller fragments or particles. This equipment plays a vital role in the plastic recycling industry and is the first key process in the plastic recycling process.

Plastic shredders are different from ordinary pulverizers. They have stronger processing capabilities and wider applicability. They can process plastic products of various shapes and sizes, including plastic barrels, plastic pipes, plastic films, plastic bottles, etc. Through shredding, the volume of plastic materials is greatly reduced, which is convenient for subsequent recycling processes such as cleaning, sorting, melting and granulation.

Working principle of plastic shredder

The core working principle of plastic shredders is based on the mechanical action of shearing, tearing and extrusion to break down large plastic materials into small fragments. The following is its detailed working process:

1. Feeding system: The material is fed into the shredder feed port through a conveyor belt or manually. Large equipment is usually equipped with a forced feeding device to ensure continuous and stable feeding.

2. Knife shearing: After the material enters the shredding chamber, it is bitten by the carbide knife on the rotating knife roller. The two sets of knife rollers that cooperate with each other rotate at a relatively low speed (usually 20-60rpm), generating a strong shear force.

3. Tearing process: The knife continuously pulls and tears the material, and at the same time produces a strong squeezing effect at the gap between the knife rollers, causing the plastic material to break.

4. Screen filtering: Some models are equipped with a screen at the bottom, and only fragments smaller than the size of the screen hole can pass through. Materials that do not meet the requirements will continue to be processed in the shredding chamber.

5. Discharging and conveying: The processed plastic fragments are discharged through the discharging port and can directly enter the next process or be transported to the designated location through conveying equipment.

The working efficiency of the plastic shredder depends on many factors, including tool design, motor power, speed control, and material characteristics. Modern high-end shredders are usually equipped with intelligent control systems that can automatically adjust the speed and torque according to the load to achieve the best shredding effect.

Core advantages of Aceretech shredders

As a professional shredder equipment manufacturer, Aceretech provides a variety of plastic shredding solutions, and its products have significant advantages in the following aspects:

1. Diverse product series to meet different needs

ACERETECH provides a full range of shredders from single-axis to double-axis, including:

- Single-axis shredder: suitable for processing softer plastics and film materials

- Double-axis shredder: universal design, can handle most plastic waste

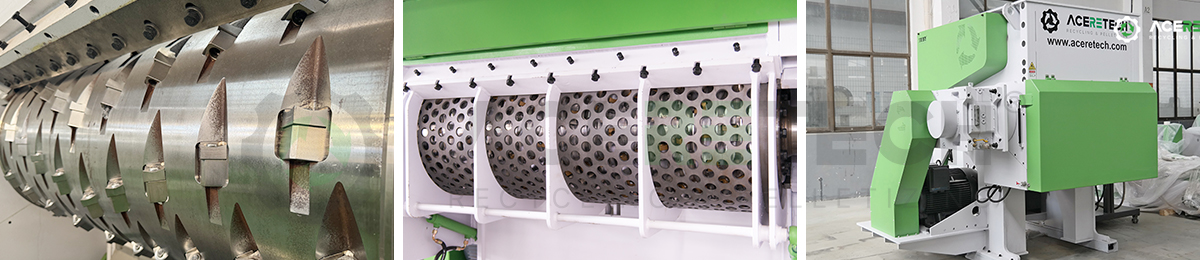

2. High-quality tool system

ACERETECH shredders use special alloy steel tools with the following characteristics:

- High hardness, strong wear resistance, long service life

- Can be sharpened multiple times to reduce the cost of use

- Unique tool design to improve shearing efficiency

- Modular structure, easy replacement and maintenance

3. Intelligent control system

ACERETECH's high-end models are equipped with advanced control systems:

- Automatic overload protection function

- Reverse anti-jamming design

- Energy consumption monitoring and optimization

Remote monitoring and fault diagnosis (some models)

4. Sturdy and durable mechanical structure

- Heavy steel structure frame to ensure long-term stable operation of the equipment

- Precision bearings and transmission system to reduce maintenance requirements

- Optimized sound insulation and noise reduction design to improve the working environment

5. Customized solutions

ACERETECH can provide according to customer's special needs:

- Customized output particle size of different sizes

- Special solutions for special materials (such as reinforced plastics)

- Integrated system with other equipment (such as conveyors, sorting machines)

Application areas of plastic shredders

Plastic shredders are widely used in the following scenarios:

- Plastic recycling industry

- Electronic and electrical waste treatment

- Automotive plastic parts recycling

- Packaging material treatment

- Industrial plastic waste management

- Municipal plastic waste treatment

Reasons for choosing ACERETECH shredders

As a professional environmental protection equipment supplier, ACERETECH's shredder products have the following comprehensive advantages:

1. High efficiency: Optimized knife roller design and power configuration ensure high processing capacity

2. Low energy consumption: Intelligent control system minimizes energy consumption

3. Low maintenance: Durable design and convenient maintenance structure reduce downtime

4. Safety: Multiple safety protection measures ensure the safety of operators

5. Environmental protection: Comply with international environmental standards and promote sustainable development

For companies that need to deal with various types of plastic waste, ACERETECH shredders provide a reliable, efficient and economical solution. Whether it is a small or medium-sized recycling station or a large plastic recycling plant, you can find a suitable model in the Esreite product line.

By adopting advanced shredding technology, ACERETECH helps customers reduce the volume and pre-process plastic waste, creating favorable conditions for subsequent recycling and regeneration processes, and ultimately achieving maximum resource utilization and economic benefits.

Plastic Shredder: Working Principle and Analysis of ACERETECH Product Advantages

2025/07/10