How to Recycle EPE Pearl Cotton?

Polyethylene foam cotton, also known as EPE pearl cotton, is a new type of environmentally friendly packaging material with a non-crosslinked closed-cell structure. It is composed of countless independent bubbles produced by the physical foaming of low-density polyethylene.

Overcoming the shortcomings of ordinary foam rubber, such as fragility, deformation, and poor recovery, EPE pearl cotton has many advantages such as moisture resistance, shock resistance, sound insulation, heat preservation, good plasticity, strong toughness, recyclability, environmental protection, and strong impact resistance. It also has good chemical resistance. It is an ideal substitute for traditional packaging materials and is mostly used to make anti-collision packaging materials such as elastic-lined bags.

EPE pearl cotton foamed material is a new type of material which will never fade due to its special advantages, not only does it not pollute the environment, but also can be recycled repeatedly. With the development and application of products, EPE pearl cotton foam will be widely used in packaging and filling materials.

♲ Recycling Solution offer by ACERETECH MACHINERY

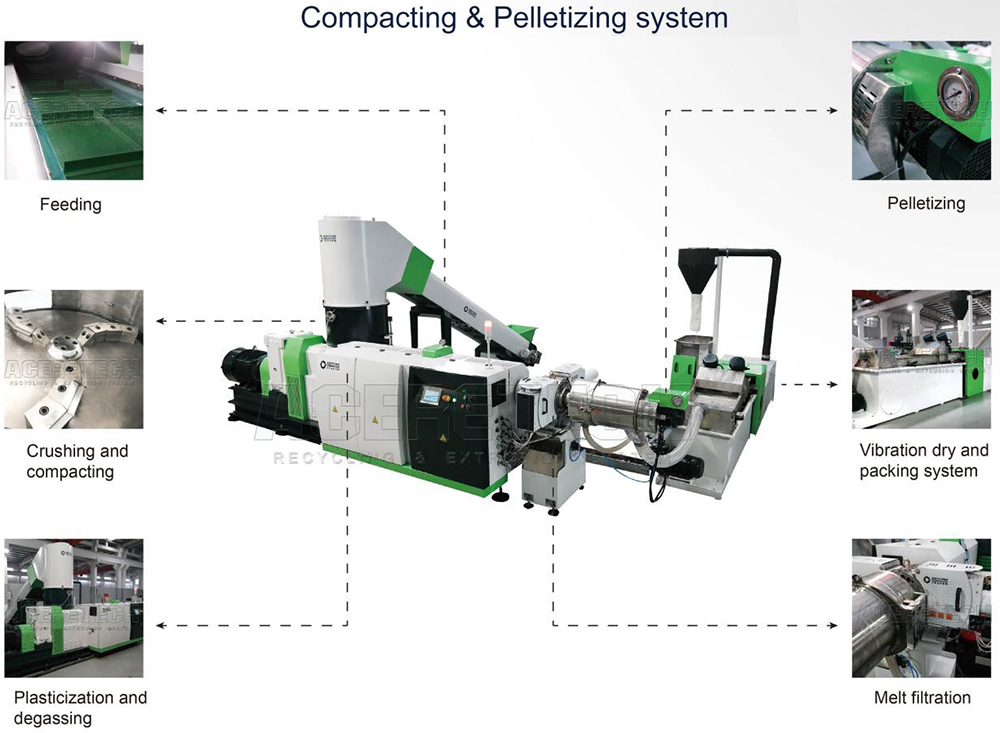

ACS-H series compacting pelletizing machine developed by ACERETECH MACHINERY is very suitable for recycling EPE pearl cotton. In the past few years, we have provided more than 6 sets of EPE pearl cotton recycling granulators for customers in 5 countries including Korea, Japan and Italy and so on.

The Belt conveyor is used to feed the EPE wastes into the compactor. The feeding speed of conveyor belt is fulling automatic based on how full the compactor’s room is.

The rotatory blades of compactor will cut up the incoming scraps. And the frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point.Optimal designed guide structure compacts the materials and directs it into extruder screw.

The plastics scraps will be well melted, plasticized in a 36D processing section. It has the double zone vacuum degassing system which is especially suitable to heavy printed film and material with water content.

For the filter system, we equip the piston-type screen changer which has the super large filter area.

For the pelletizing system, we suggest our water-ring pelletizing system. Self-adjusting pelletizing head for the best granulate quality and long uptime tanks to consistently correct blades pressure. RPM of rotatory blades is automatic based on melt extruding pressure.

The recycled particles can be used to produce pearl cotton products repeatedly, which greatly reduces the production cost of the producers.

EPE Pearl Cotton Recycling

2023/12/01

in Applications