EPE pearl cotton is widely used in packaging because of its lightweight, shockproof, and moisture-resistant properties. However, many people wonder what happens after it is discarded. Although EPE is not biodegradable, it is recyclable. With the right recycling equipment and processes, manufacturers can significantly reduce production costs and minimize environmental impact. ACERETECH introduces a complete EPE pearl cotton recycling solution, covering its recyclability, melting characteristics, and the specialized machinery that supports efficient reuse. Understanding these methods can turn waste materials into valuable resources and promote a more sustainable production cycle.

What is EPE Pearl Cotton?

EPE (Expanded Polyethylene) pearl cotton is a new eco-friendly packaging material with a non-crosslinked closed-cell structure. It is made from low-density polyethylene (LDPE) through a physical foaming process that generates countless independent bubbles.

EPE pearl cotton foam will be widely used in packaging and filling materials.

Compared to traditional foam materials, EPE pearl cotton overcomes issues such as brittleness, deformation, and poor recovery. It offers excellent properties, including lightweight, elasticity, moisture resistance, shock absorption, heat insulation, soundproofing, good chemical resistance, and strong impact resistance. Due to these advantages, it is widely used in packaging, cushioning, and construction materials.

The melting point of EPE typically ranges between 80°C and 110°C, which makes it suitable for thermal recycling processes such as melting and pelletizing.

Is EPE Pearl Cotton Recyclable?

Yes, EPE pearl cotton is recyclable. Its physical properties allow it to be reprocessed multiple times without significant degradation in quality. Recycling not only extends the material's lifecycle but also reduces raw material costs and minimizes environmental impact. Properly recycling EPE pearl cotton supports resource efficiency and aligns with the goals of a circular economy.

How is EPE Pearl Cotton Recycled?

The EPE recycling process typically involves the following steps:

The process of EPE foam recycling.

- Collection: Used or discarded EPE materials are gathered from packaging waste or manufacturing scraps.

- Pre-treatment: Materials are sorted and undergo preliminary processing, such as cutting or compressing, to reduce volume.

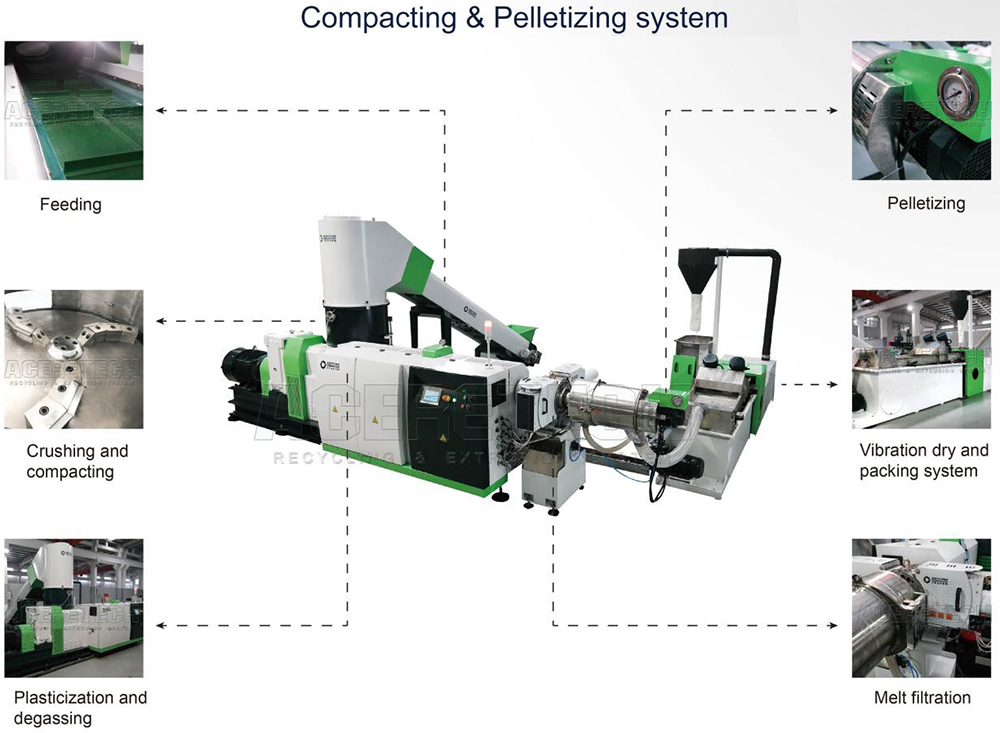

- Compacting and Pelletizing: The EPE is fed into a specialized recycling system, like the ACS-H series compacting pelletizing machine developed by ACERETECH Machinery. The machine uses a conveyor to transport the foam into a compactor, where high-speed rotary blades cut and heat the material through friction, shrinking it just below its agglomeration point.

- Melting and Extrusion: The compacted EPE is melted and plasticized in a long processing section, often with double-zone vacuum degassing to remove moisture and ink residues.

- Filtration and Pelletizing: A piston-type screen changer ensures thorough filtering, and a water-ring pelletizing system converts the melt into uniform granules. These recycled pellets can then be reused to manufacture new EPE products, significantly reducing production costs.

Environmental Impact and Sustainability of EPE Pearl Cotton

While EPE pearl cotton is considered a recyclable material, its overall environmental impact remains a concern. The production process requires large amounts of energy and resources, which can contribute to greenhouse gas emissions and environmental pressure if not efficiently managed. In addition, EPE is not biodegradable. When improperly disposed of, it may remain in landfills for decades and pose long-term risks to natural ecosystems.

Compared to expanded polystyrene foam (EPS), which is also widely used in packaging, EPE pearl cotton offers superior elasticity and durability, and it can be recycled more effectively. This makes EPE a more sustainable choice in many applications.

Although EPE pearl cotton presents certain environmental challenges, it remains non-toxic and odorless, making it suitable for food packaging and other hygiene-sensitive applications. Its moisture resistance and inability to support bacterial growth further enhance its value in repeated-use scenarios. To improve its sustainability, it is essential to establish efficient recycling systems and adopt advanced pelletizing technologies, helping manufacturers reduce environmental impact and move toward a more circular economy.

Challenges and Future Trends in EPE Pearl Cotton Recycling

Even though EPE pearl cotton is recyclable, it poses notable challenges in large-scale recycling. Its lightweight and bulky nature makes collection and transportation costly, often outweighing the value of the recovered material. Additionally, limited access to specialized recycling equipment and infrastructure further lowers the actual recycling rate in many regions.

However, ongoing advancements in recycling technologies and increasing awareness of circular economy principles are paving the way for more efficient recovery and reuse of EPE materials. As more industries invest in closed-loop systems and sustainable production practices, the future of EPE pearl cotton recycling looks promising. Emphasizing innovation in pelletizing machinery and promoting global collaboration in waste management will be key to minimizing its environmental footprint and maximizing its long-term value.

By understanding the recyclability of EPE pearl cotton and leveraging ACERETECH’s advanced recycling solutions, businesses can transform plastic waste into valuable resources and contribute to a greener, more sustainable future.