Table of contents

Ⅰ Plastic recycling

Ⅱ Plasticization regeneration method

Ⅲ Pretreatment equipment

Ⅳ Granulation equipment

Ⅴ Development prospects

plastic recycling

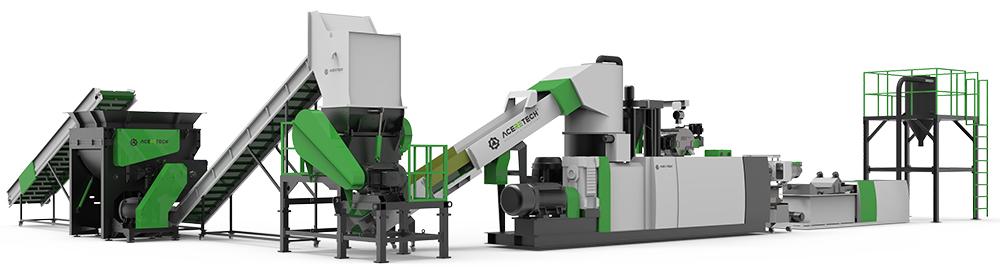

Plastic recycling machine is a general term for machinery that recycles and recycles waste plastics (daily life and industrial plastics). The plastic pyrolysis technology is still in the experimental research stage, so the plastic recycling machine mainly refers to the waste plastic recycling and granulation equipment, including pretreatment equipment and granulation equipment.

The traditional method of waste plastic treatment is landfill and incineration. Landfill not only needs to occupy a large amount of space, but if the anti-seepage measures are not appropriate, it is very easy for the generated leachate to enter the surrounding surface water or seep into the soil. Residents' health poses a serious long-term threat. Direct incineration of waste plastics may also produce dioxins to pollute the atmosphere, and the toxic and harmful substances in the bottom ash after incineration are further enriched, which still require landfill or further harmless treatment. Therefore, it is more advantageous to recycle and reuse waste plastics after sorting. Different plastics can be collected, classified and granulated for use as recycled plastics, and plastics can also be reduced to monomers through pyrolysis and other technologies to participate in the polymerization again. Recycling of resources. The recycling of waste plastics is not only environmentally friendly, but also can be recycled for secondary use, saving resources.

Plasticization regeneration method

The waste plastics are heated and melted and then re-plasticized to restore the original properties of the plastics for use, including those with lower performance than the original requirements. Plasticization regeneration can be divided into "simple regeneration" and "composite regeneration".

Simple Regeneration (Simple Regeneration)

This refers to the use of leftovers, gates, waste products and residues generated in resin production plants, plastic production plants, and plastic machining processes, including some single, batch, clean and only one-time-used waste plastics , Recycling, plasticizing and recycling of waste plastics and waste agricultural films used in disposable packaging, as a secondary material source for recycling.

In the recycling and processing of waste plastics, for simple regeneration, most plastic factories first use the waste plastics of their own factories, some plasticize, regenerate and granulate for use, some directly use after crushing and processing, and some are neither crushed nor Granulation, digested by the factory. Purely recycled materials are recycled materials that restore the original properties of plastics.

composite regeneration

The so-called waste plastic recycling mainly refers to the recycling of those waste plastics that are collected from the society in large quantities, complex varieties, many impurities and serious pollution. Among these waste plastics, there are plastic parts, packaging products, fertilizer bags, cement bags, pesticide bottles, fishing nets, agricultural films and packaging barrels scrapped from industrial and mining enterprises and agriculture, as well as food bags, plastic bottles and cans in the lives of urban and rural people. , toys, daily necessities and cultural and sporting goods made of plastic, as well as waste plastics containing a small amount of fillers and plasticizers. The composite regeneration of these miscellaneous, messy and dirty waste plastics is complicated. Composite regeneration is mostly carried out by township enterprises and small and medium-sized factories, but whether it is plasticized, recycled and granulated for sale, or directly incorporated into products for molding production, and used as a secondary material source, it must be accurately classified and selected, and impurities and oil stains must be strictly removed. Only then can the recycled material be incorporated into the product in a certain proportion. The quality of composite recycled materials is generally lower than that of pure recycled materials.

Pretreatment equipment

Waste plastic pretreatment refers to the screening, sorting, crushing, cleaning, dehydration and drying of waste plastics. Each link has its corresponding mechanical equipment, that is, pretreatment equipment. For example: plastic crushers, plastic washing machines, plastic dehydrators, of course, each type of equipment also has various models and characteristics, mainly according to the plastic raw materials and output to select the corresponding machinery.

Granulation equipment

Plastic granulation refers to the process of plasticizing, extruding and dicing broken plastics, mainly plasticizing extrusion equipment and dicing equipment. That is, we often say plastic granulator (plastic granulator) and plastic granulator. Similarly, the plastic granulation equipment used in different plastic raw materials and output is different.

Prospects

The world needs a lot of plastic products every year and consumes a lot of energy. The recycling and recycling of waste plastics is a demand for promoting a low-carbon economy and society, and it is also an urgent need. The emergence of the recycled plastic machinery industry can be said to be "send help in the snow", and at the same time, for the industry itself, this is a good opportunity and a good business opportunity.

The rise of an industry is inseparable from regulations. In the past few years, environmental protection and safety rectification actions for the waste plastics processing market have been carried out in full swing. Small workshops lacking in recycled plastic machinery technology and with imperfect scales will face the pressure of survival. If the products produced are not standardized, they will need to face punishment and social accountability. The recycled plastic machinery industry also needs to improve production technology, reduce environmental pollution, and comprehensively consider product quality and energy efficiency, in order to pursue more comprehensive, more coordinated and more sustainable development, so as to break away from single, high energy consumption Production mode, embark on the road of combined and intelligent production mode.

What machine is used for recycling plastic?

2022/05/10