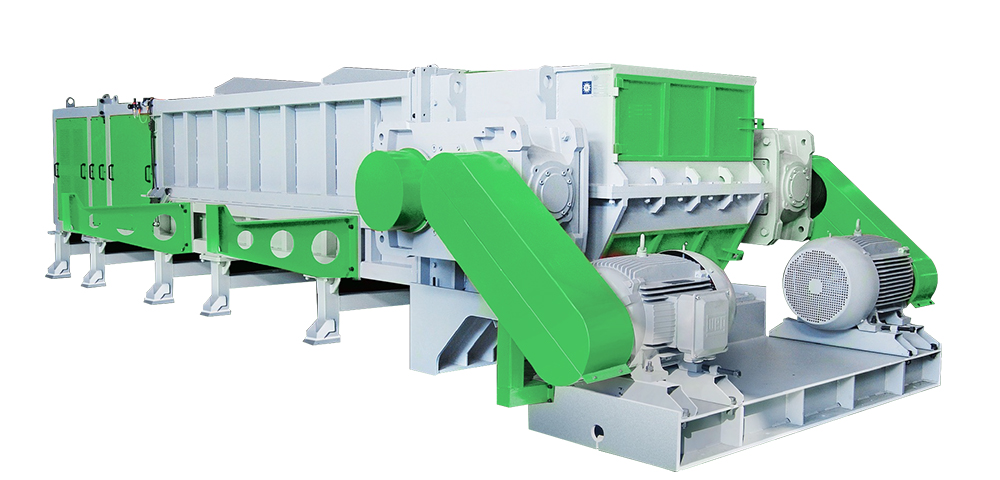

Shredder Main Shaft

The integral forging of the main shaft will not break and deform when the equipment tears high-strength materials or works for a long time.

After the manufacture of professional processing equipment such as lathe and CNC machining center, ensure that the overall error of the spindle will not exceed 0.05mm, ensure the long-term stable operation of the equipment, and ensure that the distance between fixed tool and moving tool can be adjusted to 0.5mm at least.

The special four corner design of the shredding motorized knife can be used for many times to save the cost of users.

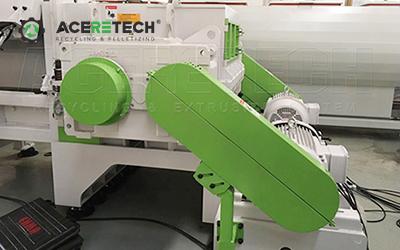

Gearbox of Shredder

Integrated box design, stronger mechanism, stronger output shaft and bearing design, longer service life and greater torque.

Flexible cooling mode to meet the requirements of thermal power.

At the same time, the output shaft adopts double oil seal design, which greatly reduces the risk of oil leakage.

Motor of shredder

The main motor adopts Weg / Siemens brand motor, with stable output and reliable quality.

Hydraulic Station

The motor, oil pump and valve group of the hydraulic station are all made of Taiwan brand, with reliable quality. The system is equipped with or150 water cooler, which can effectively control the oil temperature below 55 ° C.

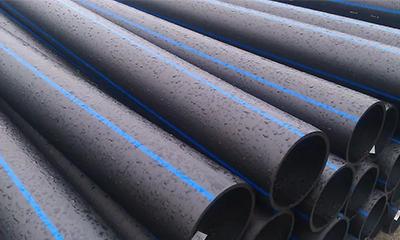

Chamber of Shredder

Chamer size can up to 6000*1200mm, which can handle diamter 1200mm, length 6m big pipes, pipes can automatic feeding into chamber through forklift or crane.

Control System of Shredder

The electrical system adopts microcomputer PLC programming control and whole process automation. After commissioning, the operator only needs to press start and stop. Save labor costs and ensure the safety of the operating environment.

Advantages

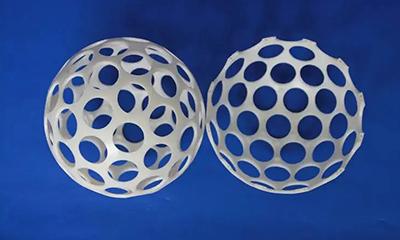

The screen mounted beneath the rotor determines the size of the required flakes. The screen is also easily accessible by a separate flap and can be changed easily. The screen can be opened or closed hydraulically.