WTS Hot Alkali Washer Online Water Recycling Treatment And Reuse System (3T/H)

WTS Hot Alkali Washer Online Water Recycling Treatment And Reuse System (3T/H)

Project profile

In the plastic cleaning process, the hot alkali washing process is usually used to clean the plastic, and the hot alkali wastewater will be generated during the cleaning process. If the hot alkali wastewater is directly discharged to the wastewater station for treatment, a large number of chemical agents and heat need to be added again, and the wastewater treatment cost of the wastewater station will be increased. Therefore, we have equipped online water treatment devices, which can greatly reduce energy consumption and the use of chemical agents, and save operating costs.

Advantages of online recycling technology

Through the online recovery technology of water treatment, 80% of hot alkali water can be recovered and reused after online recovery and disposal of hot alkali water in the cleaning process.

1. Do not add any additional water treatment agents, can realize the recovery of chemical agents, greatly reduce the use of chemical reagents;

2. Heat recovery, short online processing process, less heat loss, reduce heating energy consumption;

3.Waste water reuse, reduce water consumption, reduce wastewater treatment costs;

4. High degree of automation, automatic ratio of chemical concentration;

5. The water quality is stable and the cleaning effect is better.

Design principles

1.According to the sewage quality and treatment requirements, the process route shall be reasonably selected, the treatment technology shall be advanced, and the treated water quality shall meet the discharge standard.

2.On the premise of meeting the treatment requirements, the original facilities shall be used as much as possible to reduce the investment, and the requirements for beauty in the plant shall be considered.

3.Convenient operation and management, simple operation and simple maintenance. The equipment and equipment are of high quality, good performance and stable operation.

Design parameter

1.Waste water source

Plastic recycling plant cleaning line hot alkali wash

2.Designed treatment capacity:3m³/H

Treatment technology

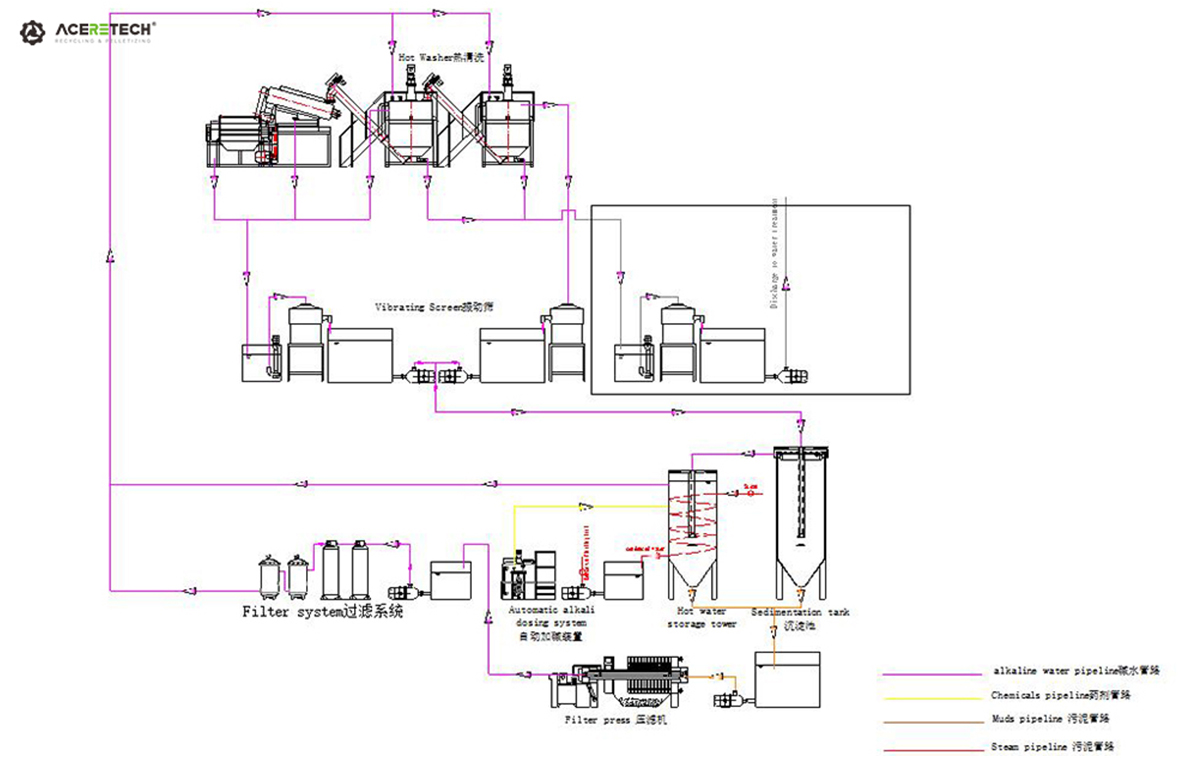

process flowchart

For our hot alkali water filtration system, the main objective is to remove the SS from the water and retain the agent in the water. This system adopts precipitation + filtration process.

Process flowchart as following:

Main Process introduction

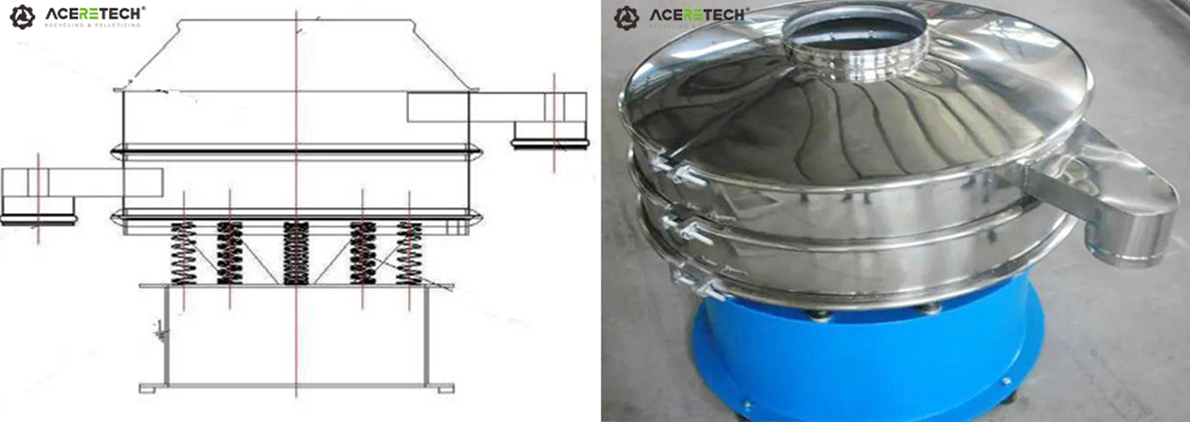

a.Grille system (round screen)

The circular vibrating screen is set at the liquid end of the hot washing pot, which mainly separates the larger particles in the outgoing alkali water, which is conducive to subsequent precipitation treatment and reduce the wear of subsequent equipment.

Model:YZS1000*1set

Main Materail:SUS304

b.Sedimentation tank

Sedimentation tank adopts vertical flow sedimentation tank, the water enters from the center pipe in the middle of the sedimentation tank from top to bottom, and the umbrella baffle is provided at the bottom to make the wastewater rise slowly from around evenly, and the mud and water are separated by gravity, so as to clarify the water quality.

The water storage tower adopts a vertical water tower to store the purified alkaline water, and at the same time, a small amount of agents are added through the automatic dosing device to adjust the PH of the alkaline water to the best.

Sedimentation tower: SLCDT-3000*1

Hot water tower: RST-3000*1

Material: SUS304

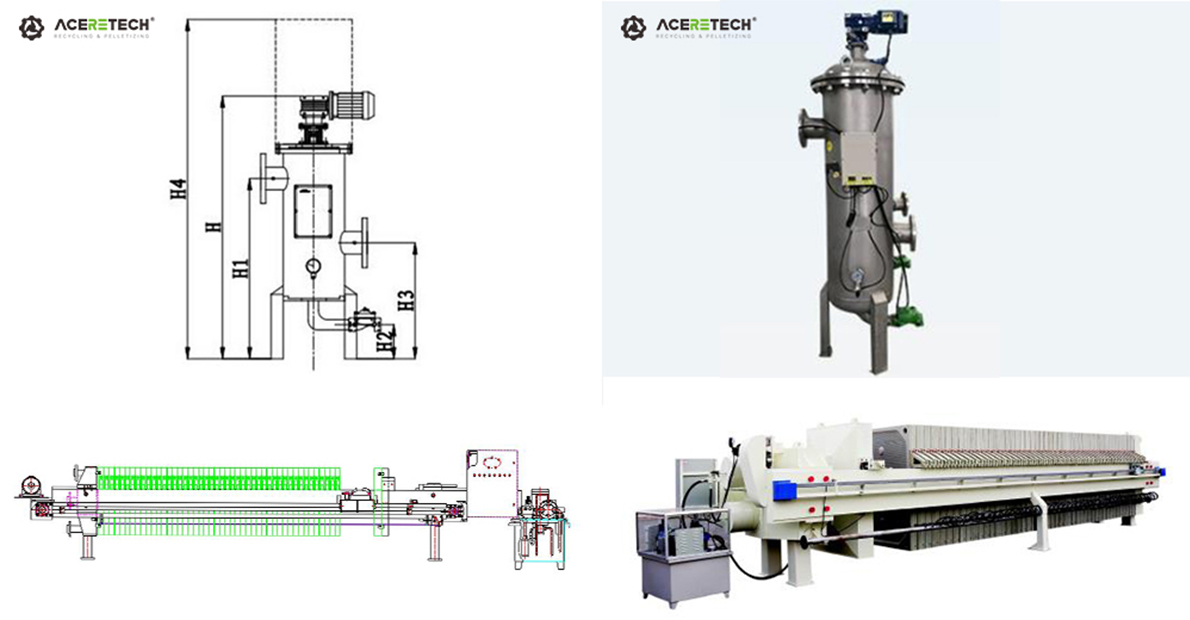

c.Filtration system

The filtration system is mainly composed of intermediate water tank, filter pump and filter press unit, and the small suspended matter is intercepted after the wastewater is filtered through the filter cloth, the water quality is clarified, and the sludge is dehydrated and transported for treatment.

Filter press: 630 *1

Filter: ZQX-30 type *2

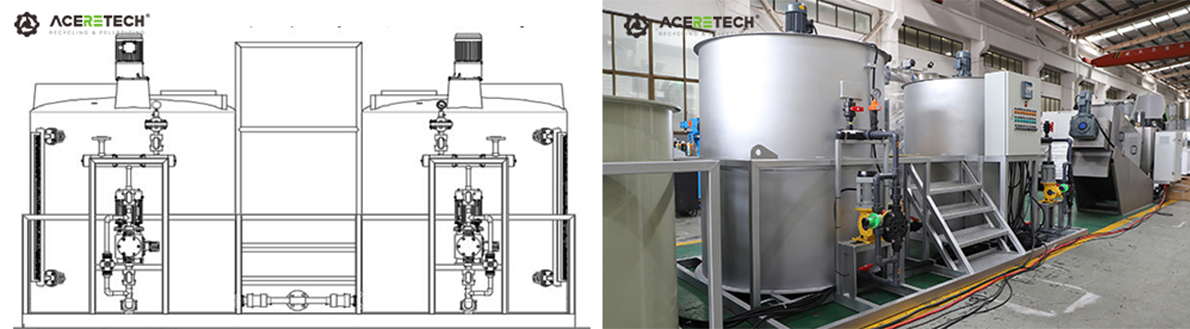

d.Dosing system

The dosing device is composed of a metering pump, a medicine barrel, a stirrer, etc., which is used to realize the quantitative dosing of medicine. The automatic dosing device is used to adjust the PH of the wastewater. The on-line PH device controls the automatic dosing of the metering pump to realize the PH stability of the wastewater within the range required for hot alkali washing.

Automatic dosing device: ZDJYZZ-1000 type *1

Material: SUS304