R-PET Food Grade Pelletizing Line

The safPET recycling system can be integrated with PET product production lines, such as bottle preform injection molding machines, spinning lines, and packaging tape production lines, to achieve one step online recycling and production of products.This reduces the material handling process, lowers the energy consumption of the entire production line, and thereby improves production efficiency. maximizing the circular regeneration of PET bottles.

Recycling & Material

Features:

* The vacuum compaction bin equipped with pre-crystallization drying functionality ensures that the raw materials are thoroughly dried and prevents yellowing of the bottle flakes due to oxidation.

* Precrystallization drying using frictional heat is more energy-saving compared to electric heating.

* A set of three-stage Roots vacuum pumps ensures the effective removal of volatile substances.

* Automatic backwashing waste discharge filters ensure filter accuracy and reduce the frequency of replacement for the melt filter screen.

* Online viscometer for real-time detection of melt viscosity, visualizing the viscosity of the extruded melt.

* Automatic strands cutting and pelletizing saves labor and ensures uniform final chips' dimensions.

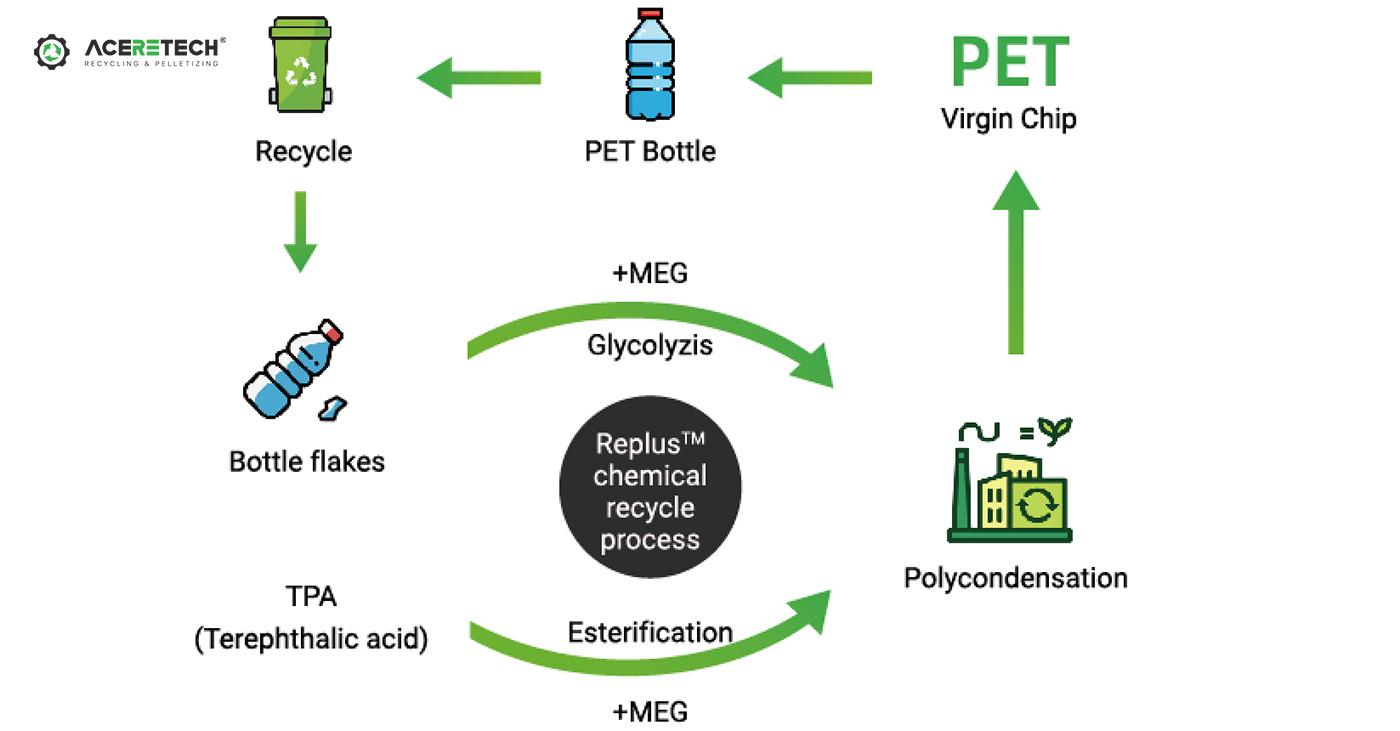

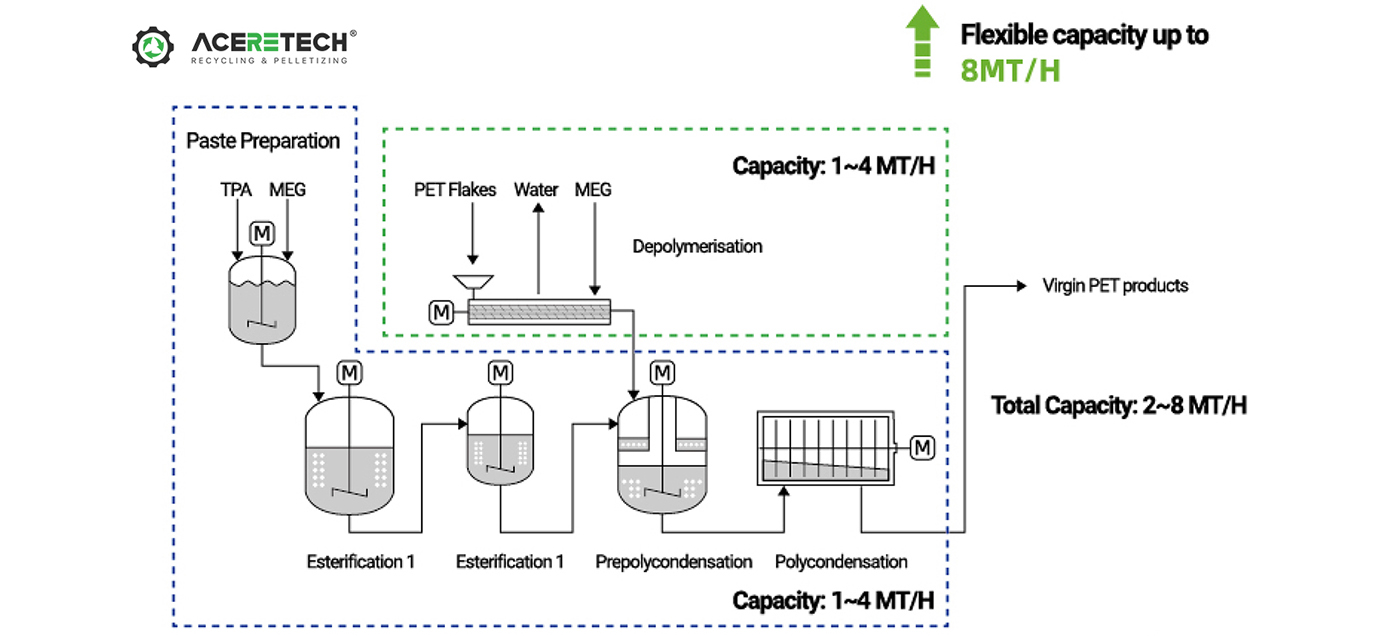

R-PET Chemical Recycling Technology

The chemical recycling process is based on PET bottle flakes,which are filtered and adapted in their intrinsic viscosity before being introduced as a melt side-stream back into the prepolymer of the prepolycondensation process.

Chemical Recycling Process

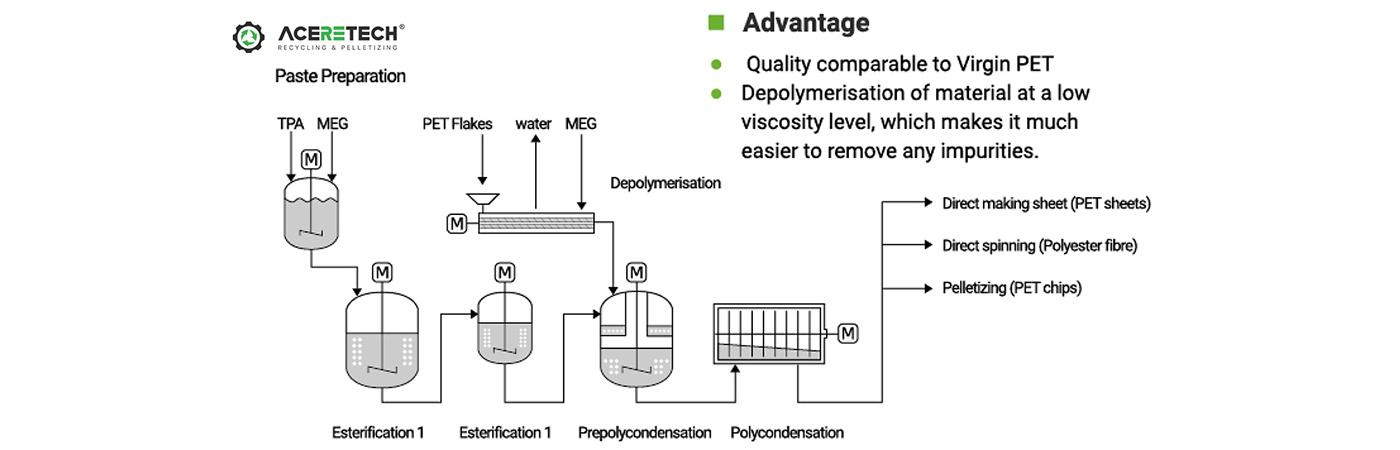

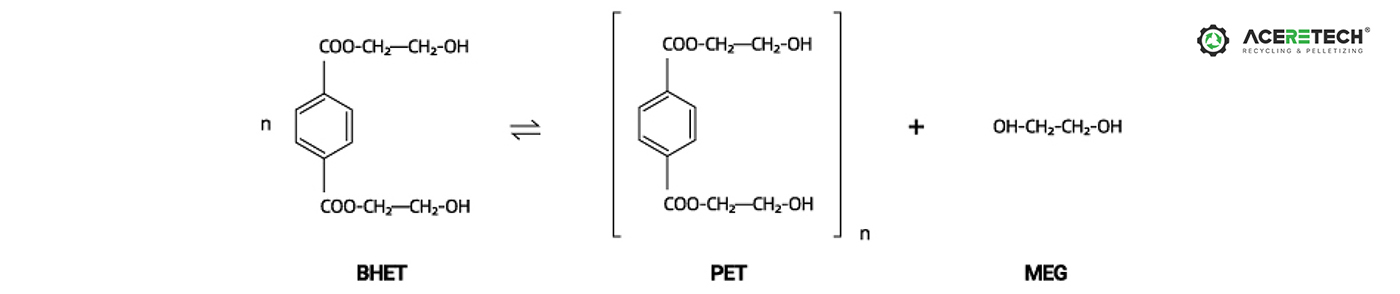

Depolymerisation reaction

Polycondensation reaction

Flexible production capacity can use up to 50% PET bottles and 50% virgin PET, and also can complete the production of Virgin PET products.

One-Step Solution for R-PET Recycling Applications

The safPET recycling system can be integrated with PET product production lines, such as bottle preform injection molding machines, spinning lines, and packaging tape production lines, to achieve one step online recycling and production of products.This reduces the material handling process, lowers the energy consumption of the entire production line, and thereby improves production efficiency. maximizing the circular regeneration of PET bottles.

FAQ

Q1: How does the Aceretech food-grade rPET granulation line ensure compliance with FDA and EFSA standards?

A: Aceretech's safPET granulation system is specifically designed to produce high-purity, food-contact-grade recycled polyethylene terephthalate (rPET). The production line utilizes multi-stage devolatilization and deep purification technologies to thoroughly remove adhesives, inks, and harmful contaminants from the bottle flakes. More importantly, the system is equipped with an SSP (Solid State Polymerization) system, ensuring that the acetaldehyde (AA) content and impurity residues in the recycled pellets fully comply with the stringent food safety regulations of the US FDA and the EU EFSA.

Q2: How does this equipment increase the iV value (intrinsic viscosity) of rPET during the granulation process?

A: The food-grade granulation line integrates advanced SSP (Solid State Polymerization) or LSP (Liquid State Polymerization) systems. By precisely heat-treating the pellets under vacuum, moisture is effectively removed, and molecular chains are reconnected, restoring or increasing the rPET's iV value to the target level (e.g., above 0.80 dl/g). This allows the recycled material to be used not only for sheet extrusion but also for demanding Bottle-to-Bottle blow molding applications.

Q3: Why is Aceretech's rPET granulation line more energy-efficient than traditional equipment?

A: Aceretech employs a "One-Step Solution" technology, seamlessly integrating bottle flake drying, continuous extrusion, and granulation processes. The equipment is equipped with an intelligent online viscometer and a precision temperature control system, reducing energy losses caused by secondary material heating. Furthermore, while ensuring 99.9% purity, the system significantly reduces electricity consumption per ton of output through optimized screw design and a vacuum degassing system, contributing to carbon emission reduction goals.

Q4: Can this production line process PET waste from different sources (such as bottle flakes, sheets, or fibers)?

A: Yes. The food-grade granulation line has excellent material adaptability. In addition to processing conventional post-consumer PET bottle flakes, by adjusting the pretreatment and feeding systems, it can also efficiently process PET scraps, waste fibers, and films. We provide customized crushing and cleaning pre-treatment solutions for different types of raw materials, ensuring that the color and transparency (L/a/b values) of the final product remain stable.

Q5: What turnkey services can Aceretech provide for food-grade recycling projects?

A: Aceretech provides a complete set of turnkey services, from factory layout design and equipment selection to installation and commissioning. Considering the complexity of food-grade projects, we assist clients in optimizing the process flow and support them in applying for relevant certifications such as FDA LNO (No Objection Letter). We utilize a remote diagnostic system to provide 24-hour online monitoring of production status, ensuring the long-term stable operation of the production line.