SSP (Continuity) PET Plastic Recycling Machine Line with Solid State Polymerization For IV Increase

SSP (Continuity) Pet Waste Recycled Plastic Pelletizing Machine For IV Increase

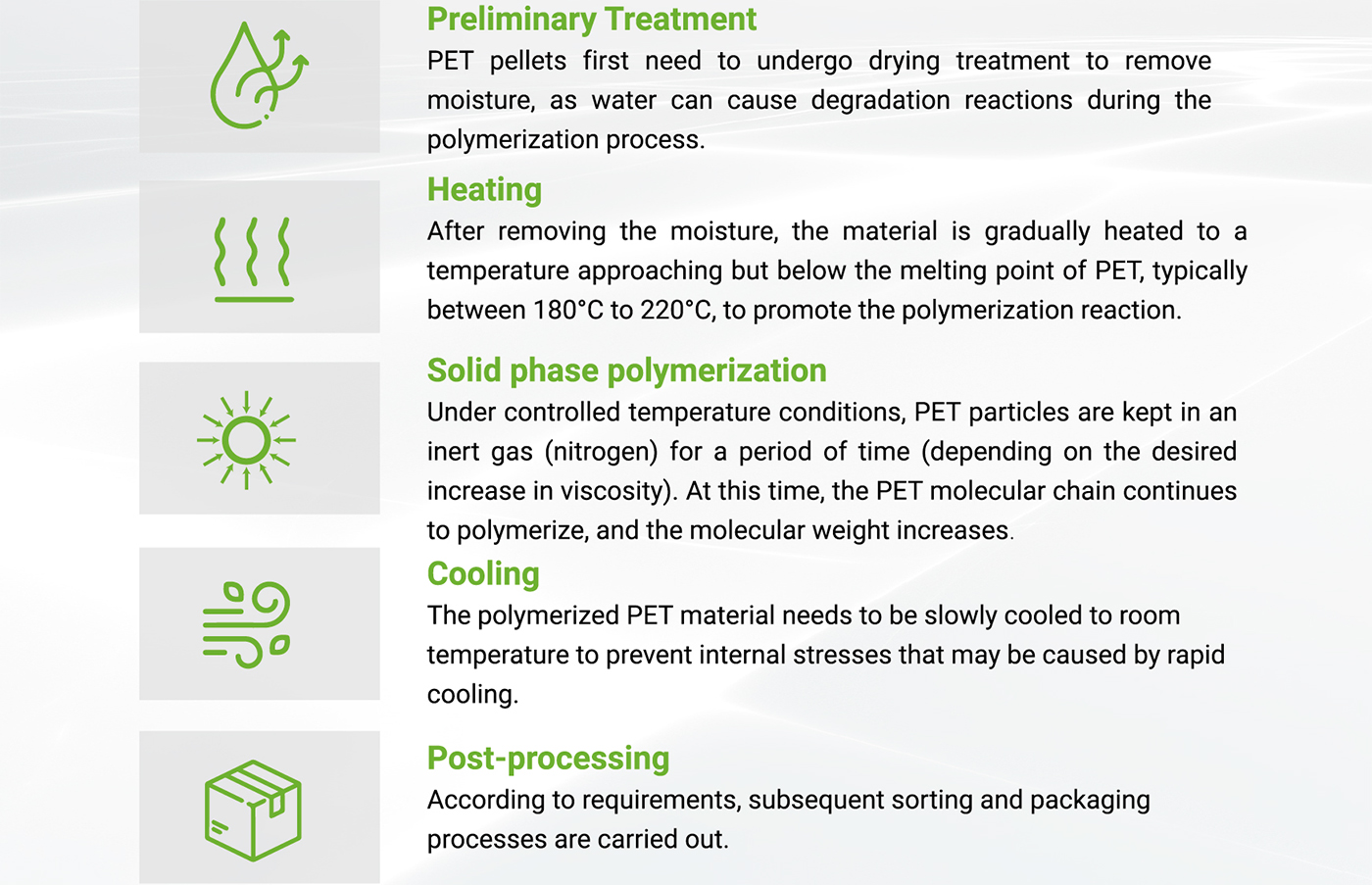

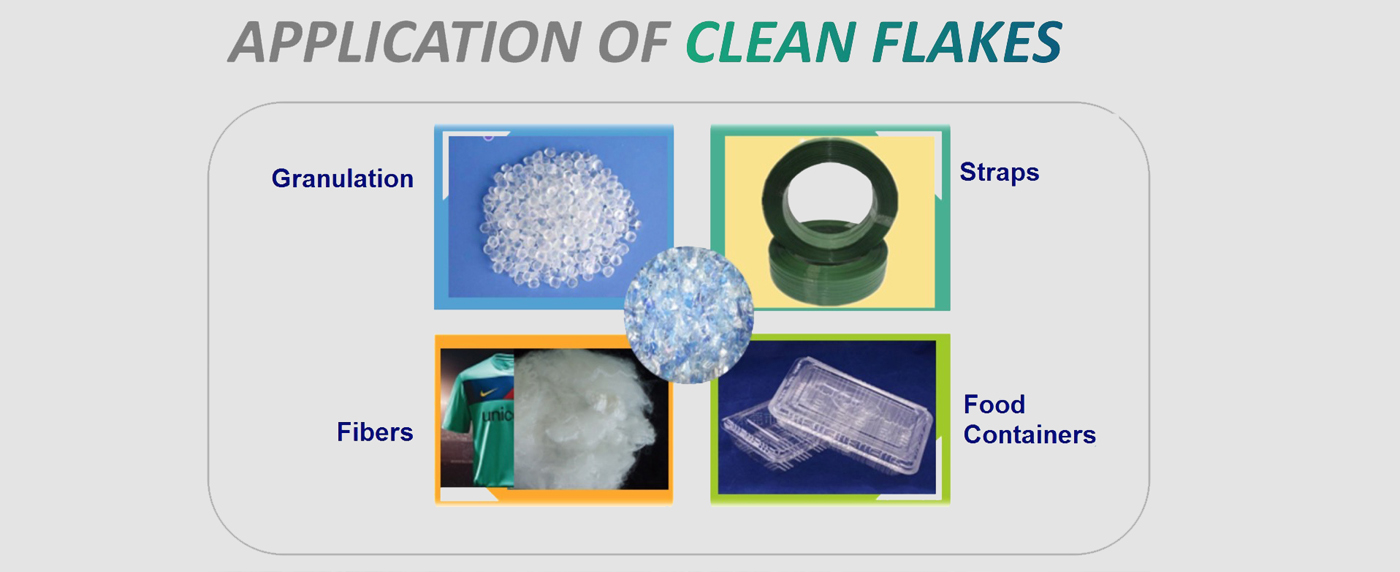

Solid state polymerization (SSP) is a post-processing technique used to increase the molecular weight of polyethylene terephthalate (PET), which in turn enhances the melting point, mechanical properties, and chemical stability of PET. This process is commonly employed in the production of bottle preforms and other PET products. The solid state polymerization process takes place attemperatures below the glass transition temperature and above the melting point of PET, allowing the PET particles to remain in a solid state.The advantage of solid state polymerization (SSP) lies in its ability to increase the molecular weightof PET without compromising the material's properties. This is directly related to the performance of the final product, such as improved mechanical strength and enhanced chemical stability.Further more, the SSP process can also remove low molecular weight substances from the material, such as residual monomers and oligomers, thereby increasing the purity of the product. SSP (Solid State Polymerization) is an indispensable step in the manufacturing of PET bottles, containers, packaging tapes, and other engineering plastic products, especially for applications that require high-performance PET.

Recycling & Material

SSP (Continuity) Pet Waste Recycled Plastic Pelletizing Machine For IV Increase

The latest efficient recycling solution. Thanks to the vacuum technology, the SSP IV increasing technology, and the pelletizing extruder specially made by Aceretech, the IV value of the final PET granules can meet the requirements, and this value can be stably maintained. Even there are uneven IV values and moisture content of the raw materials, the final pellets can be maintained at a reasonable, qualified IV value within a set interval, meanwhile the quality and the output are always stable. It can maintain a stable IV value output for further downstream processing and molding, such as stretch blow molding, up to 100% bottle-to-bottle technology in new bottles.

* Higher viscosity increase efficiency, with a maximum actual viscosity increase of 0.02 per hour.

* Two sizes, 12000L and 24000L, modular design, can be freely combined according to production capacity.

* Digital control, user-friendly interface, easy to operate.

* Compared to traditional polymerization processes, the production assembly is modularized andminiaturized, making post-maintenance and operation simple.

FAQ

Q1: What is SSP technology? What role does it play in PET recycling?

A: SSP (Solid State Polymerization) is a key technology for improving the quality of recycled PET (rPET). Aceretech's SSP system effectively removes volatile impurities and allows for the repolymerization of molecular chains by subjecting PET flakes to prolonged heat treatment in a high-temperature vacuum environment. This not only significantly increases the intrinsic viscosity (iV value) of rPET, bringing it to "bottle-to-bottle" grade, but also ensures that the material meets food contact safety standards.

Q2: How does this equipment ensure the stability of the intrinsic viscosity (iV value) of the produced rPET pellets?

A: Stability is core to food-grade recycling. Aceretech's continuous SSP granulator is equipped with a high-precision online viscosity detection system and a PID temperature control loop. By precisely controlling the retention time of the material in the reactor and the purity of the nitrogen circulation, the system can control the iV value deviation within a very small range, ensuring excellent process consistency for downstream customers when blowing bottles or producing high-strength filaments.

Q3: Can this continuous SSP granulator meet FDA or EFSA food-grade standards?

A: Yes. Aceretech's SSP technology is specifically designed for Bottle-to-Bottle recycling projects. This process can thoroughly remove harmful chemicals and contaminants, and the purified rPET pellets fully comply with US FDA and EU EFSA food packaging regulations. We not only provide equipment but also assist customers in optimizing their process flow to successfully pass relevant food safety challenge tests.

Q4: What are the advantages of a continuous SSP granulator compared to traditional batch systems?

A: Compared to batch systems, Aceretech's continuous SSP system has the following significant advantages:

Higher energy efficiency: Continuous production reduces energy loss during repeated heating processes.

Uniform quality: Avoids performance differences between batches, resulting in better color values (L/b values) of the produced pellets.

High degree of automation: Greatly reduces the need for manual intervention and supports 24/7 uninterrupted operation, significantly increasing annual output and return on investment (ROI).

Q5: What are the requirements for the moisture content and purity of the raw materials (PET bottle flakes) for this equipment?

A: To obtain high-quality food-grade pellets, we recommend that the moisture content of the PET bottle flakes entering the granulator be less than 1%, and the impurity content (such as PVC, PE/PP, or metals) be controlled within 50 ppm. Aceretech's granulation line integrates an efficient preheating and dehumidification system and multi-stage vacuum degassing at the front end, which can handle a certain range of material fluctuations. However, the quality of the upstream cleaning line will directly affect the efficiency of the SSP system in increasing the iV value.