Unlocking Efficiency in PET Recycling: ACERETECH Double Shaft Shredder and Comprehensive Shredder Solutions

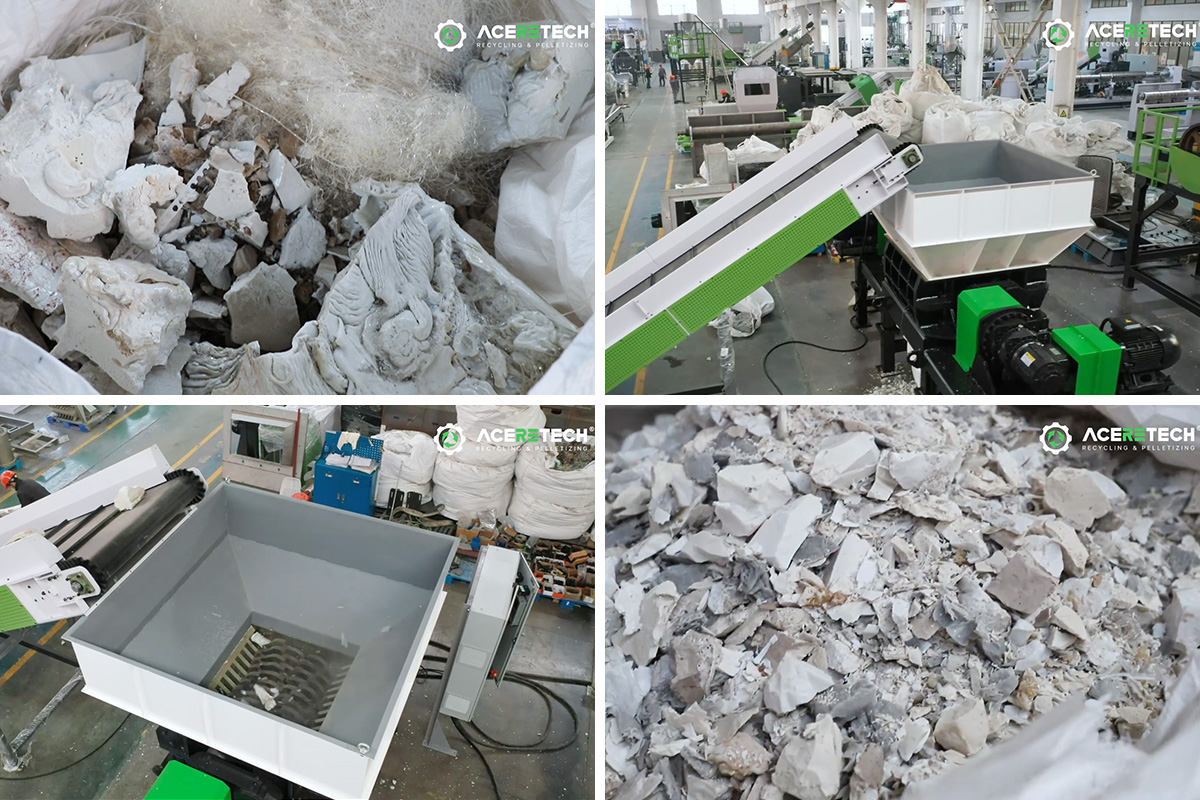

In the evolving plastic recycling industry, handling tough materials like PET (polyethylene terephthalate) lumps and straps remains a pressing challenge. These durable strapping materials, often used in packaging heavy goods, are notoriously difficult to break down with conventional equipment. That’s where ACERETECH’s Double Shaft Shredder steps in—offering a powerful, efficient, and reliable solution purpose-built for this demanding task.

But ACERETECH doesn’t stop there. As a leader in plastic recycling innovation, ACERETECH offers a comprehensive range of shredders, each engineered to tackle different materials and recycling stages—from rigid plastics to bulky waste—ensuring end-to-end support for sustainable material recovery.

Why PET Lumps and Straps Require Specialized Shredding

PET lump straps are designed for strength and resilience, making manual processing inefficient and traditional shredders prone to wear and damage. Efficiently shredding these materials is crucial not only for ease of handling but also for preparing them for downstream granulation or pelletizing processes. Poor shredding leads to inconsistent output, increased downtime, and higher operational costs.

ACERETECH Double Shaft Shredder: Engineered for Performance

The ACERETECH Double Shaft Shredder is purpose-built to meet these challenges head-on. Designed with high-performance components and customizable features, it delivers:

- Dual-Shaft Efficiency: Its dual-rotor design ensures uniform shredding of PET straps and lumps, producing consistent output ideal for further processing.

- High Output Capacity: With throughput reaching up to 1 ton per hour, it supports industrial-scale recycling operations without compromising quality.

- Durable Components: A high-strength rotor with excellent wear and impact resistance ensures long-term, stable performance, even under continuous heavy-duty use.

- Smart Automation: An integrated belt conveyor system reduces manual labor, improves feeding consistency, and increases overall production continuity.

- Premium Electrical System: Equipped with European-imported electrical components to ensure operational safety, precision, and durability.

More Than One Machine: ACERETECH's Complete Recycling Shredder Series

While the Double Shaft Shredder is a flagship product for PET processing, ACERETECH’s plastic recycling shredder series extends beyond one solution. The lineup includes:

- Single Shaft Shredders: Ideal for precision shredding of rigid plastics and large-diameter pipes.

- Crusher and Granulator Systems: Designed for high-speed size reduction of post-consumer and post-industrial plastic waste.

- Integrated Shredding Lines: Tailored solutions combining shredders, washers, dryers, and extruders for a complete closed-loop recycling system.

Each shredder is customizable to meet specific customer requirements, ensuring flexible deployment across diverse recycling and manufacturing environments.

Proven Results: Real-World Impact

Numerous companies in the logistics, packaging, and manufacturing sectors have effectively incorporated ACERETECH shredders into their operations. For instance, a prominent packaging company reported improved efficiency in waste processing and enhanced recycling capabilities after implementing the Double Shaft Shredder, contributing to more sustainable operations.

These success stories highlight the tangible benefits of selecting a solution that combines engineering excellence with customizable flexibility.

A Look Ahead: Sustainability and Market Growth

With increasing global awareness around environmental sustainability and stricter waste management regulations, demand for advanced recycling equipment is surging. ACERETECH’s solutions not only address today’s recycling challenges but also support tomorrow’s circular economy goals. The company remains committed to innovation, continuously refining its shredder series to deliver higher efficiency, reduced environmental impact, and smarter automation.

Ready to Upgrade Your Recycling Line?

Whether you're dealing with PET straps, rigid plastics, or mixed industrial scrap, ACERETECH has a solution for you. Our team is ready to provide customized equipment that fits your exact needs.

Contact us today to learn more about the Double Shaft Shredder and discover how our full range of plastic recycling shredders can enhance your operations and contribute to a more sustainable future.