I. EPS foam: lightweight and versatile plastic material

EPS (expandable polystyrene) foam, also known as foam plastic, is a lightweight plastic material with excellent heat insulation, sound insulation and shockproof performance. It is widely used in packaging, construction, decoration and other fields. However, EPS foam is large in volume and low in density, and it is difficult to degrade naturally. The disposal of its waste has also become an environmental problem that needs to be solved urgently.

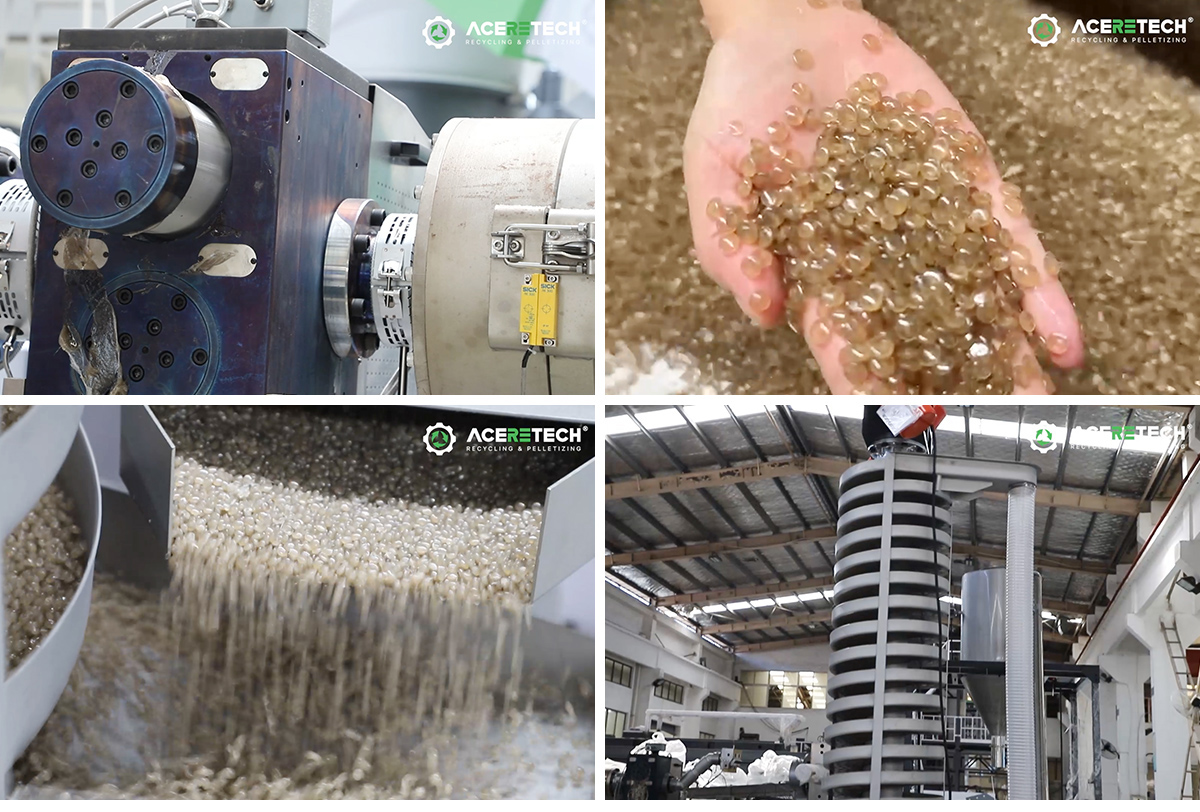

II. EPS foam pelletizing: realizing resource recycling

EPS foam pelletizing is the process of processing EPS foam into recycled plastic particles through crushing, melting, extrusion, pelletizing and other processes. Recycled plastic particles can replace part of the original plastic and be used to produce various plastic products, such as photo frames, decorative lines, skirtings, etc., so as to realize the recycling of resources and reduce environmental pollution.

According to customer needs, ACERETECH customizes an EPS foam pelletizing production line for customers, which mainly includes the following equipment:

Belt conveyor with metal detection: It is used to evenly transport EPS foam to the production line, detect and remove metal impurities in it, and protect subsequent equipment.

Dust removal device: used to remove dust and impurities on the surface of EPS foam to ensure product quality.

Two-stage single screw extruder: Using a two-stage single screw extruder, after two extrusions, the plastic melt is more uniform and the product quality is more stable.

Two-stop piston filter (None-Stop Piston Type Filter): Adopt a two-pass filtration system to effectively remove impurities in the melt and ensure that the particles are purer.

Water ring pelletizer: Adopt a water ring pelletizing method to ensure that the particles are uniform in shape and smooth on the surface.

Intelligent touch screen control: Adopt an intelligent touch screen control system to realize automatic control of the production process, easy to operate, and one-button start and stop.

Dehydration vibration screen: Used to remove moisture from the surface of particles.

Lifting and drying equipment: Used to further dry the particles to ensure that their moisture content meets the requirements.

Silo: Used to store finished particles and realize automatic weighing and packaging.

IV. Summary

EPS foam pelletizing is an effective way to solve the problem of EPS foam pollution and realize resource recycling. This production line can efficiently process EPS foam into high-quality recycled plastic particles, which can be used to produce various plastic products, turning waste into treasure and contributing to the development of the circular economy.

Click the link below to view the factory test video.