Ⅰ. HDPE/LDPE packaging bags: widely used plastic materials

High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are two common plastic materials, which are widely used in the production of packaging bags due to their excellent performance. HDPE packaging bags have high strength, rigidity and chemical resistance, and are often used in shopping bags, garbage bags, food packaging bags, etc. LDPE packaging bags are softer and more transparent, and are often used in plastic wrap, plastic bags, packaging films, etc.

However, if HDPE/LDPE packaging bags are not properly handled after a large number of uses, they will cause serious pollution to the environment. Therefore, recycling and reusing HDPE/LDPE packaging bags and converting them into renewable resources is of great significance to reducing white pollution and developing a circular economy.

Ⅱ. ACERETECH: Customized recycling and pelletizing solutions

As a leading company in the field of plastic recycling and pelletizing, ACERETECH is committed to providing customers with efficient, environmentally friendly and intelligent customized solutions based on customer needs. For the recycling and pelletizing of HDPE/LDPE packaging bags, ACERETECH has customized the following configurations for customers:

1000L pellet silo:

large capacity design to meet continuous production needs and improve production efficiency.

Double-stage single screw extruder with a diameter of 140mm:

adopts a two-stage design, the first stage is used for plasticization and preliminary mixing, and the second stage is used for homogenization and pressurization to ensure that the material is fully plasticized and evenly mixed, and improve product quality.

Belt feeding with metal detector:

effectively removes metal impurities in raw materials, protects subsequent equipment, and improves product purity.

Dust removal device:

effectively removes dust and impurities in raw materials, improves production environment, and improves product quality.

SCF self-cleaning filtration system and non-stop piston filter (None-Stop Piston Type Filter) double filtration:

SCF self-cleaning filtration system can automatically clean the filter screen online to ensure continuous production; non-stop piston filter can replace the filter screen without stopping the machine, further improving production efficiency.

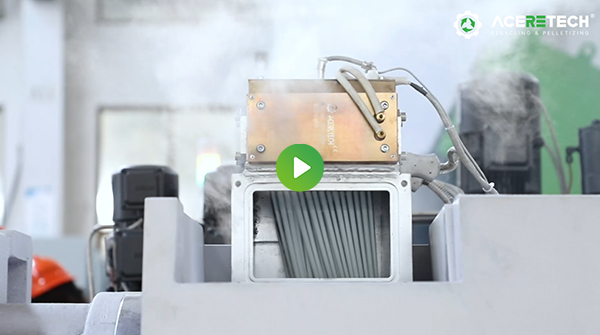

Water ring pelletizing:

adopts water ring cooling and cutting, the pellets are uniform, not easy to stick together, and improve product quality.

Double vacuum degassing:

effectively removes moisture and volatiles from the material, improves product quality and stability.

Intelligent touch screen control:

friendly human-machine interface, easy operation, can realize automatic control, improve production efficiency and stability.

Vibration dewatering screen:

effectively removes moisture on the surface of the pellets and improves drying efficiency.

Centrifugal dehydrator:

further removes moisture on the surface of the pellets and improves product quality.

Weighing silo:

accurate measurement, convenient for subsequent packaging and transportation.

III. Advantages of ACERETECH solution

Efficient:

high degree of automation, high production efficiency, can meet the needs of large-scale production.

Environmental protection:

adopts advanced dust removal and filtration technology to effectively reduce pollution emissions and meet environmental protection requirements.

Intelligent:

adopts intelligent control system to realize automatic production, improve production efficiency and stability.

Customization:

provide customized solutions according to customer needs to meet the production needs of different customers.

IV. Conclusion

ACERETECH’s HDPE/LDPE packaging bag recycling and pelletizing solution provides customers with an efficient, environmentally friendly, and intelligent recycling and reuse method, which helps accelerate the development of the circular economy and build a sustainable, green future.

As a leading innovator in plastic recycling machinery, ACERETECH offers a comprehensive turnkey solution—from material collection, sorting, and washing to extrusion, pelletizing, and automation control. Our integrated systems are meticulously designed to handle post-consumer and post-industrial plastic waste, transforming used packaging films, shopping bags, agricultural films, and industrial scraps into high-quality regenerated plastic pellets ready for reuse in manufacturing.

Our turnkey approach ensures seamless project implementation:

- Customized System Design tailored to your capacity, feedstock, and end-product requirements

- Advanced Automation & IoT Integration for real-time monitoring, energy optimization, and minimal labor intervention

- Eco-Friendly Technology with water recycling systems, low emission profiles, and energy-efficient motors

- High Purity Output achieved through multi-stage filtration and degassing, ensuring consistent pellet quality for demanding applications

- End-to-End Support including installation, training, commissioning, and after-sales service

By choosing ACERETECH, businesses not only enhance operational efficiency but also fulfill environmental, social, and governance (ESG) goals. Our solutions empower plastic recyclers, manufacturers, and municipalities worldwide to turn waste into value, reducing landfill burden, conserving resources, and supporting global sustainability targets.

Together, we’re not just recycling plastic—we’re redefining its lifecycle.

Get a Quote Now!

Click the link below to view the factory test video.