Ⅰ. Bolsas de embalaje HDPE/LDPE: materiales plásticos ampliamente utilizados

El polietileno de alta densidad (HDPE) y el polietileno de baja densidad (LDPE) son dos materiales plásticos comunes que se utilizan ampliamente en la producción de bolsas de embalaje debido a su excelente rendimiento. Las bolsas de HDPE tienen alta resistencia, rigidez y resistencia química, y se utilizan con frecuencia en bolsas de compras, bolsas de basura, bolsas para embalaje de alimentos, etc. Las bolsas de LDPE son más suaves y más transparentes, y se utilizan comúnmente en envoltorios plásticos, bolsas plásticas, películas de embalaje, etc.

Sin embargo, si las bolsas de embalaje HDPE/LDPE no se manejan adecuadamente después de un uso prolongado, pueden causar una grave contaminación ambiental. Por lo tanto, el reciclaje y la reutilización de bolsas de embalaje HDPE/LDPE y su conversión en recursos renovables son de gran importancia para reducir la contaminación blanca y desarrollar una economía circular.

Ⅱ. ACERETECH: Soluciones personalizadas de reciclaje y peletizado

Como una empresa líder en el campo del reciclaje y peletizado de plásticos, ACERETECH se dedica a proporcionar a los clientes soluciones personalizadas, eficientes, ecológicas e inteligentes basadas en las necesidades del cliente. Para el reciclaje y peletizado de bolsas de embalaje HDPE/LDPE, ACERETECH ha diseñado las siguientes configuraciones para los clientes:

Silo de peletizado de 1000L: diseño de gran capacidad para satisfacer las necesidades de producción continua y mejorar la eficiencia de la producción.

Extrusora de un solo tornillo de dos etapas con diámetro de 140 mm: utiliza un diseño de dos etapas, la primera etapa se usa para plastificación y mezcla preliminar, y la segunda etapa para homogeneización y presión, asegurando que el material esté completamente plastificado y mezclado uniformemente, mejorando la calidad del producto.

Alimentación por correa con detector de metales: elimina eficazmente las impurezas metálicas del material, protege el equipo posterior y mejora la pureza del producto.

Dispositivo de eliminación de polvo: elimina eficazmente el polvo y las impurezas del material, mejora el ambiente de producción y mejora la calidad del producto.

Sistema de filtración autolimpiante SCF y filtro de pistón sin interrupción (Filtro de tipo pistón sin detención) con doble filtración: el sistema de filtración autolimpiante SCF limpia automáticamente la pantalla del filtro en línea para garantizar una producción continua; el filtro de pistón sin interrupción permite cambiar la pantalla del filtro sin detener la máquina, mejorando aún más la eficiencia de la producción.

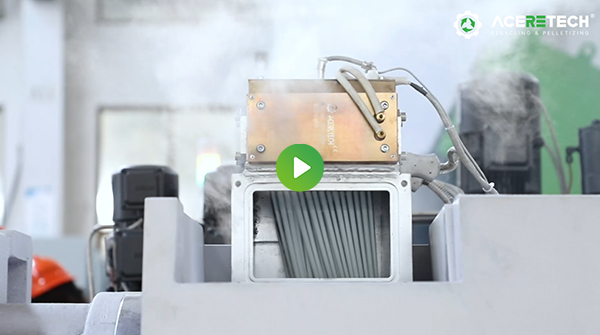

Peletizado con anillo de agua: utiliza enfriamiento y corte con anillo de agua, las pellets son uniformes, no se pegan fácilmente, lo que mejora la calidad del producto.

Desgasificación al vacío doble: elimina eficazmente la humedad y los volátiles del material, mejorando la calidad y la estabilidad del producto.

Control con pantalla táctil inteligente: interfaz amigable para el usuario, fácil de operar, puede realizar control automático, mejorando la eficiencia y estabilidad de la producción.

Pantalla de deshidratación vibratoria: elimina eficazmente la humedad de la superficie de las pellets y mejora la eficiencia de secado.

Deshidratador centrífugo: elimina aún más la humedad de la superficie de las pellets y mejora la calidad del producto.

Silo de pesaje: medición precisa, conveniente para el posterior embalaje y transporte.

III. Ventajas de la solución ACERETECH

Eficiencia:

alto grado de automatización, alta eficiencia de producción, puede satisfacer las necesidades de producción a gran escala.

Protección ambiental:

utiliza tecnología avanzada de eliminación de polvo y filtración para reducir eficazmente las emisiones de contaminantes y cumplir con los requisitos de protección ambiental.

Inteligencia:

adopta un sistema de control inteligente para realizar una producción automática, mejorando la eficiencia y estabilidad de la producción.

Personalización:

proporciona soluciones personalizadas según las necesidades del cliente para satisfacer las necesidades de producción de diferentes clientes.

IV.Conclusión

La solución de reciclaje y pelletización de bolsas de embalaje HDPE/LDPE de ACERETECH ofrece a los clientes un método eficiente, ecológico e inteligente de reciclaje y reutilización, lo que ayuda al desarrollo de la economía circular y la construcción de un futuro verde.

Haga clic en el siguiente enlace para ver el video de prueba de fábrica.

Reciclaje y peletización de bolsas de embalaje de HDPE/LDPE

2025/07/21