With the deepening of global circular economy policies by 2025, the closed-loop recycling of PET (polyethylene terephthalate) bottle flakes has become a focus of the plastics industry. ACERETECH, a company deeply rooted in plastic recycling technology, has launched the ASE series single-screw granulator, which, with its excellent purification capabilities and extrusion efficiency, has become the preferred equipment for global customers processing PET waste.

Why is PET bottle flake recycling and pelletizing a trend in the industry?

Efficient PET bottle flake recycling and pelletizing machines can not only significantly reduce the carbon footprint but also transform waste plastics into high-value recycled R-PET pellets. These pellets are widely used in:

High-standard textiles: Production of recycled polyester filaments.

Environmentally friendly packaging: Meeting food-grade and industrial-grade packaging requirements.

Precision manufacturing: Used in automotive parts and consumer electronics.

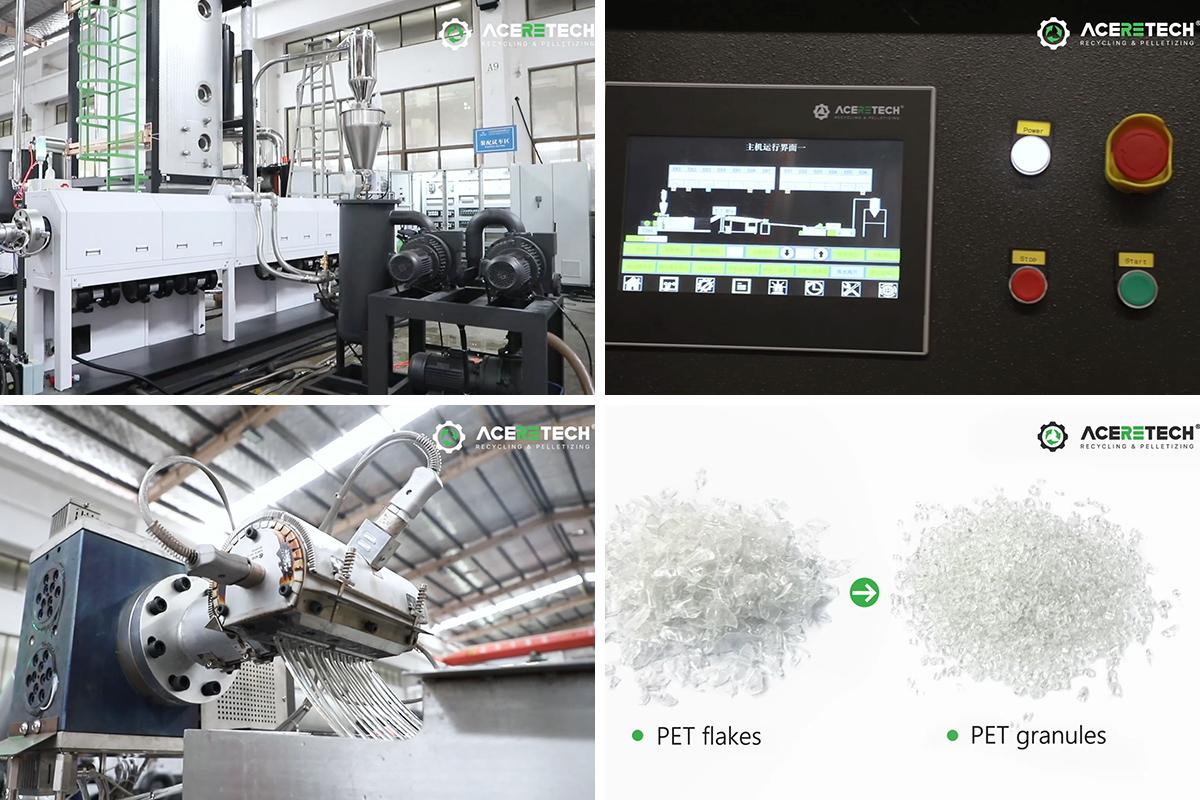

The ASE series is designed to address the challenges of PET's high thermal sensitivity, easy degradation, and moisture sensitivity. The following are its core system advantages:

High-precision feeding and drying: Equipped with a precision metering scale and clean drying equipment to ensure material dryness and stable proportioning from the source.

Visual intelligent control: Equipped with an intelligent PLC control system and a material viewing window, supporting one-button start and real-time monitoring of the melting state.

Dual vacuum degassing technology (core): The powerful dual vacuum degassing zone efficiently removes impurities, monomers, and volatile substances from the melt, effectively preventing a significant drop in viscosity (IV value).

Continuous production guarantee: The non-stop piston-type filter (screen changer) ensures the filtration of fine impurities without interrupting production, improving particle purity.

High-quality pelletizing system: Combining water-cooled strand pelletizing and a vibrating dewatering screen, the resulting pellets are uniform in size, dry, and transparent in appearance.

Output Product: Clean and Transparent High-End Recycled Pellets

The pellets produced by the ACERETECH ASE single-screw granulation line have excellent transparency and physical properties. This high-quality output can directly compete with virgin materials, significantly enhancing the premium capabilities and market competitiveness of recycling companies.

Industry Applications and Market Outlook for 2025

With global brands mandating the inclusion of PCR (post-consumer recycled plastic) content, the demand for recycled PET is continuously surging. ACERETECH ASE equipment not only meets environmental compliance requirements but also significantly reduces labor costs and energy consumption through automation, making it an ideal investment for medium to large-scale recycling plants seeking industrial upgrades.

Summary and Consultation

ACERETECH is committed to providing customized plastic recycling solutions for global customers. The ASE single-screw granulator is the culmination of technological expertise and market feedback.

Want to learn more about the detailed specifications of ASE equipment or get a quote?

👉 Click here to watch a factory trial demonstration video

👉 Contact our technical experts for a one-on-one solution design.