At Aceretech, we specialize in designing and delivering advanced plastic recycling solutions that empower businesses worldwide to embrace sustainability while maintaining high production efficiency. Recently, we completed a project in Pakistan, where we engineered and installed a fully integrated PET bottle flakes recycling pelletizing line tailored for local operational conditions and client requirements.

This custom-built system allows our client to transform post-consumer PET bottle flakes into top-grade recycled pellets, paving the way for potential upgrades that will enable them to meet food-contact standards in the future. This supports the circular economy of plastics.

Project Background and Client Needs

The client from Pakistan was looking for a reliable way to transform clean PET flakes from collected waste bottles into market-ready pellets with consistent quality and minimal contamination. Their key objectives were:

- To establish a fully automated recycling line

- Ensure compliance with international food contact safety standards

- Achieve stable output capacity (targeting around 500 kg/h)

- Integrate seamlessly with existing cleaning and washing systems

After an in-depth consultation, our engineering team designed a modular and scalable solution that meets all technical and regulatory demands.

System Overview and Key Features

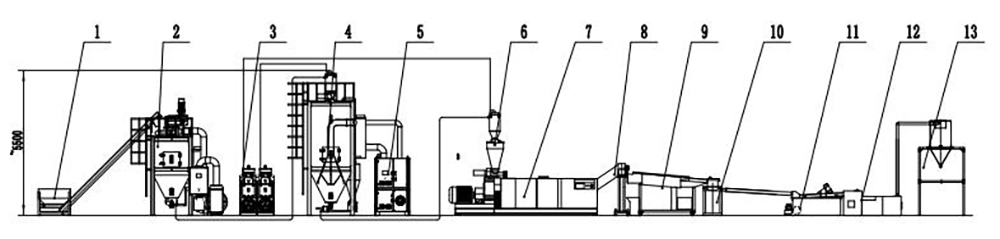

The turnkey PET flake-to-pellet system includes the following core components:

- Flake Drying System: A dual-stage dehumidifying dryer ensures thorough moisture removal before extrusion, which is critical for achieving high-quality pellets.

- Twin-Screw Extruder with Melt Filtration: Our proprietary ATE series co-rotating twin-screw extruder offers superior mixing and degassing performance, while the advanced filtration system effectively removes impurities.

- Underwater Pelletizing Unit: Ensures uniform pellet size and shape, enhancing downstream usability in injection molding and film applications.

- Cooling and Packaging Integration: Streamlined post-processing system for easy handling and storage of finished pellets.

All components are controlled via a centralized PLC system, enabling remote monitoring and diagnostics to ensure optimal uptime and maintenance efficiency.

Technical Adaptations for Local Conditions

One of the major challenges was adapting the system to fluctuating environmental humidity levels and variable input flake moisture content. Our engineers optimized the drying parameters and added real-time moisture sensors to dynamically adjust processing conditions, ensuring consistent pellet quality throughout the year.

Additionally, the system was built with energy-efficient components and designed for ease of operation, even in areas with limited technical resources.

Sustainability Impact and Market Potential

By converting waste PET bottles into high-quality recycled pellets, this facility plays a vital role in reducing dependence on virgin plastic materials and minimizing plastic waste pollution. The resulting rPET pellets can be used in a variety of applications, such as

- Textile fiber production

- Thermoforming sheets

- Industrial strapping

- Non-food packaging materials

These uses support the transition toward a more circular economy, where waste is transformed into valuable resources. Aceretech is committed to promoting sustainable development by providing innovative recycling technologies to industries worldwide.

Client Feedback and Project Outcome

Our customer expressed strong satisfaction with the system’s performance, noting its stability, ease of operation, and the support provided during installation and commissioning. “From concept to delivery, Aceretech demonstrated professionalism and technical expertise,” said a company representative. “We’re confident this line will help us grow sustainably.”

This successful implementation in Pakistan highlights Aceretech’s ability to deliver customized, high-performance recycling lines that meet diverse global needs. If you're looking to start or upgrade a rPET pelletizing plant, Aceretech offers end-to-end solutions, including process design, equipment supply, installation, and after-sales service.

If you’d like to learn more about our PET recycling systems or discuss your specific requirements, please feel free to contact us today.

Topic: PET Bottle Recycling