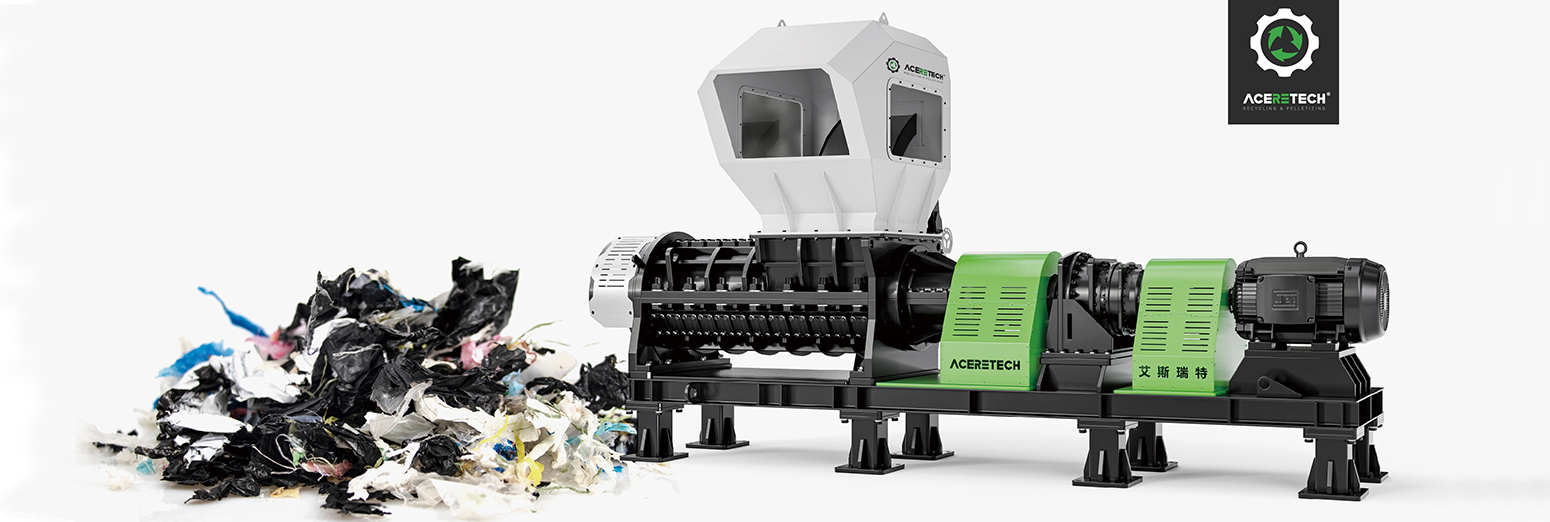

DTS Plastic Shredder for Flexible Materials

DTS Plastic Shredder for Flexible Materials (films, bags, fiber, filament, cloth, yarns) Recycling

ACERETECH DTS series shredder is a shredder specifically designed for flexible materials such as films, bags, fiber, filament, cloth, yarns etc. This shredder integrates shredding and crushing functions, and the size of the shredded material can be directly applied to the pelletizing extruder. The shredder shaft adopts disk type blades, which shred materials to specific sizes according to specific arrangements and combinations.

Specifications

| Product Parameter | |

| Model | Shredder DTS |

| Raw material | Film, woven bags ,pipes. Profiles, etc all kinds of plastics |

| Electric current | 3×380V, 50Hz; control current 220V, 50Hz |

| Capacity (Kg/H) | 1000~2000 (The output varies according to the material, shape, specific gravity, material properties, etc.) |

| Description of final product | Particle size: 20mm-100mm(can be designed as per special requirement) |

| Number of shafts (n) | 1 |

| Blade specification | Material: Forged wear-resistant rigid |

| Principal axis | Material: 40Cr, heat treatment hardness HB250-280 (tempered) |

| Stationary knife | Material: H13 steel (forging tool) Rockwell hardness 54-57 HRC |

| Coupling | The link between the main engine and the reducer adopts the drum type tooth connection, and the transmitted torque is large |

| Cutting Chamber Material | 16Mn welded shell |

| Bearing | One unidirectional thrust ball bearing, one cone roller bearing, two angular contact ball bearings with lock outer ring, and one aligning roller bearing (NSK brand) |

| Motor protection class | IP55 |

ACERETECH DTS disk type shredder can handle many kinds of material, compared with traditional shredder and crusher two step system, DTS combines shredding and crushing in one machine, the biggest capacity can reach 2ton/h.

description

Shredder Shaft

The DTS shredder shaft is forged from alloy structural steel and precision machined by CNC, meeting the manufacturing requirements for high precision. The shaft adopts a national standard spline connection to the knife disk, with high torque performance, making it easy to handle in high-speed cutting.

Motor

Main motor adopts WEG brand. High transmission efficiency, capable of converting a high proportion of input electrical energy into mechanical energy, thereby saving costs; Stable output and reliable quality.

Gearbox

The gearbox body is made of high-strength ductile iron, and the internal gear is directly used as the outer shell. Compared with ordinary planetary gearboxes in China, it has the advantages of high load-bearing capacity per unit volume, low noise, and long service life.

Discharge Port

The discharge port adopts an adjustable screen mechanism, which flexibly controls the discharge size to meet customer needs.The scraper is made of hot work die steel forging and precision machining, which enables the steel surface to effectively resist wear and reduce material loss during continuous friction with the material

PLC

Siemens PLC automatic control, can give start or stop signals to the feeding belt according to the current of the shredder.

FAQ

Q1. What types of soft materials are best suited for the Aceretech DTS series shredder?

A: The DTS series is a single-shaft shredder specifically designed for flexible/soft materials. It is particularly suitable for processing large rolls of agricultural film (LDPE/LLDPE), packaging film, bulk bags (FIBCs), PP woven bags, fibers, and artificial turf. Compared to ordinary shredders, the DTS series features an optimized rotor design for these easily stretched, high-toughness materials, effectively addressing the difficulties encountered when shredding soft materials.

Q2. How does this equipment solve the problem of soft plastics easily wrapping around the rotor during shredding?

A: The DTS series employs a specialized anti-winding rotor design. Through optimized blade holder layout and high-precision blade gap control, the material is quickly cut after being fed in, rather than wrapping around the main shaft. This design not only improves cutting efficiency but also significantly reduces the risk of equipment overheating or downtime due to material entanglement, ensuring continuous production.

Q3. How durable are the blades of the DTS series shredder? Is replacement convenient?

A: The DTS series uses four-sided reversible blades made of high-hardness alloy steel (DC53 or D2). When one cutting edge becomes dull, the operator simply rotates it 90 degrees to obtain a new sharp edge, extending the lifespan of a single set of blades by four times. In addition, the equipment features a hydraulically assisted casing opening function, allowing maintenance personnel easy access to the shredding chamber for blade replacement or routine inspections, greatly reducing downtime and long-term operating labor costs.

Q4. Why is the DTS series shredder more efficient when processing large rolls of film?

A: The equipment is equipped with an advanced built-in hydraulic ram. When large rolls of film or bundles of woven bags are fed into the hopper, the hydraulic system automatically adjusts the thrust based on the main shaft load, powerfully pushing the material towards the rotor. This "intelligent feeding" method avoids material bridging and idling, making the DTS series more than 30% more efficient than traditional equipment when processing large volumes of flexible materials.

Q5. How can the DTS series be integrated into existing plastic washing or granulation production lines?

A: The DTS series shredders feature a modular design and are equipped with a Siemens PLC integrated control panel. They can be easily integrated with downstream belt conveyors, screw conveyors, or crushers. Through communication protocols, the shredder's operating status (such as current and speed) can be synchronized with the entire washing or granulation line, enabling fully automated control. This makes it a core pre-processing unit for building high-performance rPET and rPE recycling plants.