Easypure Smart Plastic Pellets Odor Removal Solution

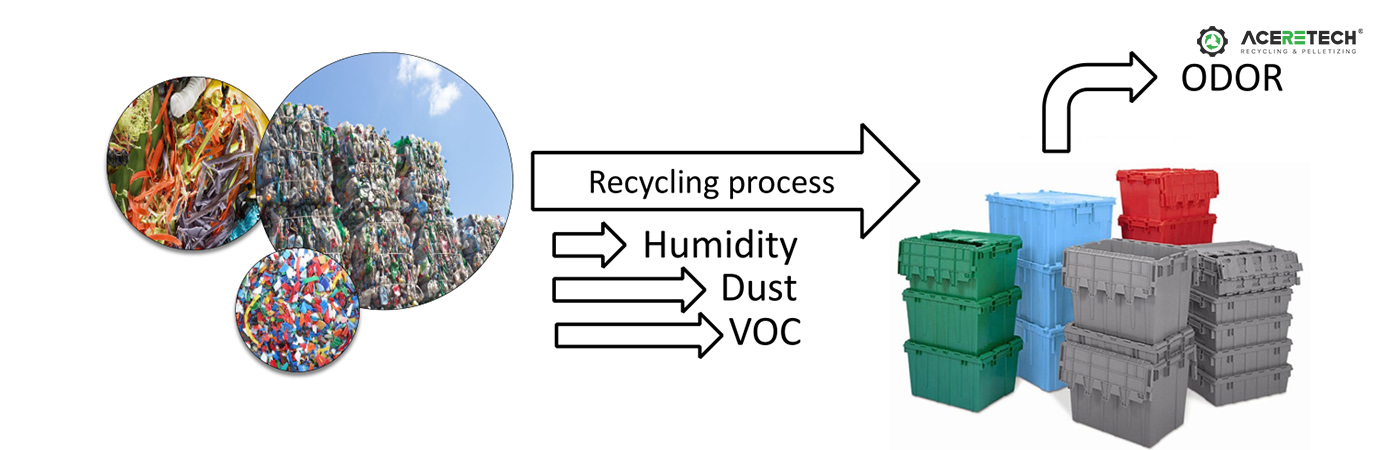

Plastic Recycling

Recycling and regeneration are playing an increasingly important role in the world of plastics driven by new circular economy models.

The biggest problems in recycling plastic are the bad smell in the final product and VOC humidity and dust in the process. Odor is relevant in recycled olefinic resins such as rPE, rPP and rHDPE.

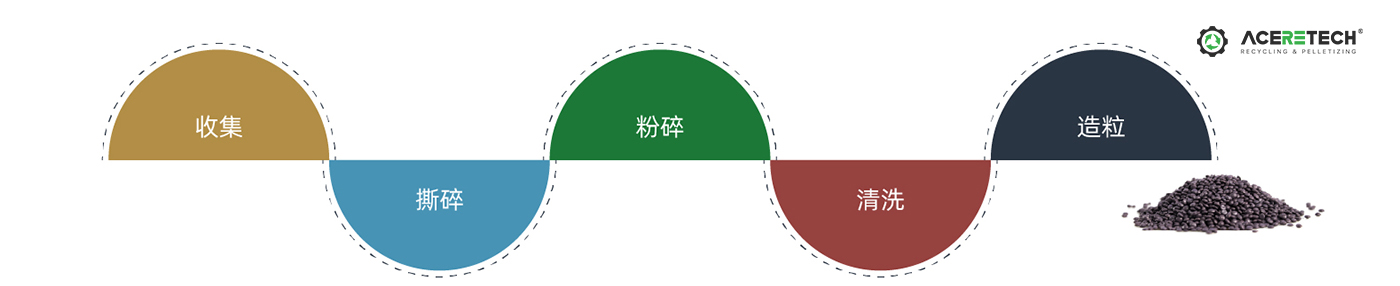

Plastic Recycling Process

As much as this process can be precise, the outlet granule still contain a high quantity of pollutant substances that can damage final products and causing odours.

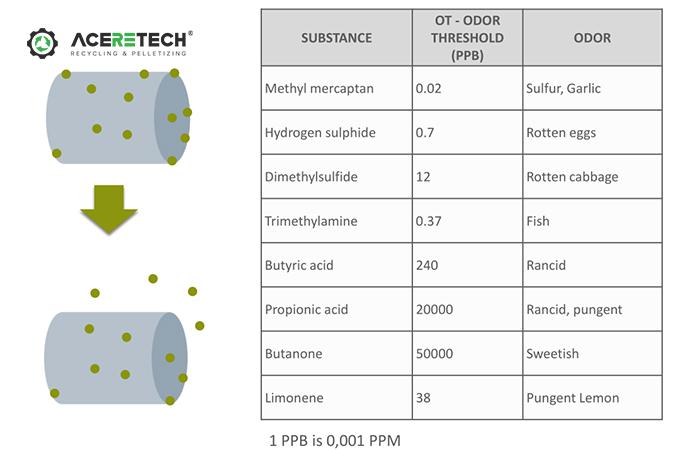

Odor

Inside and in the surface of the granule there are different types of molecules that may cause odor.

Depending on the vapor pressure of the molecules, some are able to escape at environmental temperature,and they cause the odor when achieving the OT - odor thresholds.

Easypure

Easypure is the solution to strip away volatile substances and contaminants in recycled plastic exploiting a hot air flow that heats the material inside the hopper end it is also the carrier to strip away the smelly substances.

Easypure can be used to reduce the intrinsic emission of compounds produced with virgin material.

Easypure is provided with:

* ESP blower unit

* Deodoriser hopper

The system can be monitored by two control versions:

* Basic, with standard control functions

* Advance with complete functionalities for total control of the deodorizing island Two control versions can monitor the system.

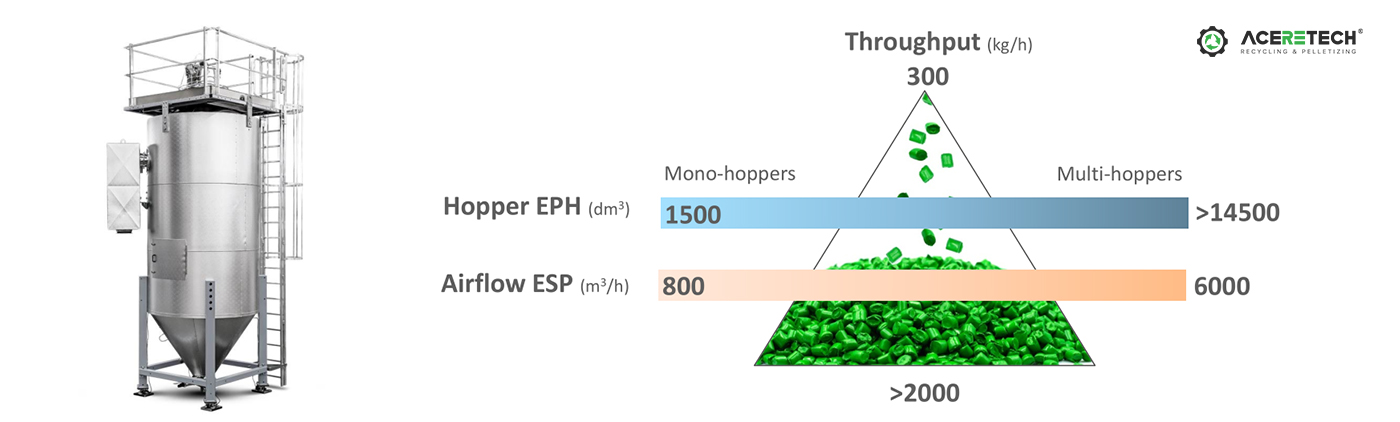

Easypure-EPH Hopper

* The Easypure hopper is designed to maximize the stripping effect through hot air flow and provide homogeneous heat to allow the release of odorigenic substances without overheating.

* Hopper is insulated to avoid heating loss and can be equipped with ladders

* Hopper can be equipped with level sensors or load cells

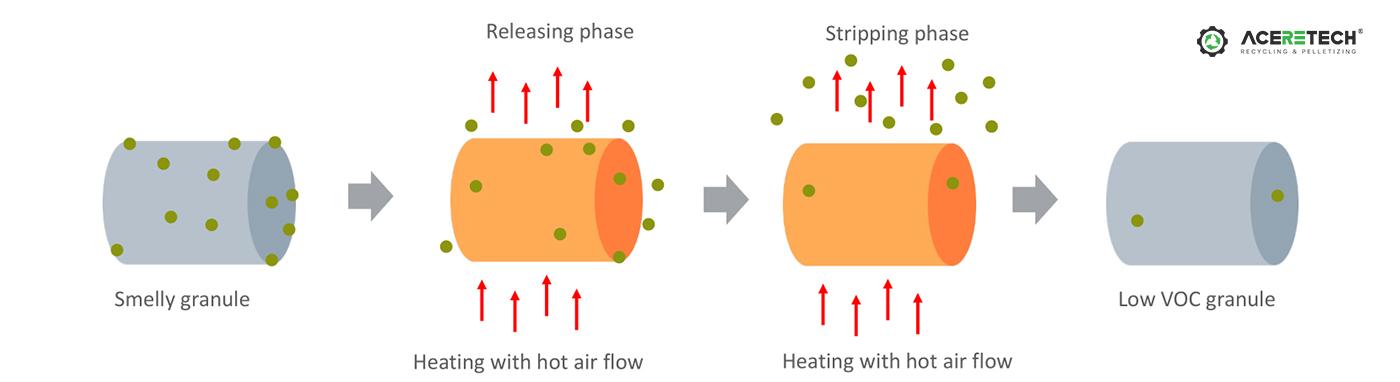

Deodorising Principles

Easypure exploits the effect of temperature on the kinetics of molecules by increasing their diffusion within the granule and their ability to be released into the air.

Releasing and stripping phase occur at the same time driven by hot air flow that provides heat and is also the carrier to strip away the VOC.

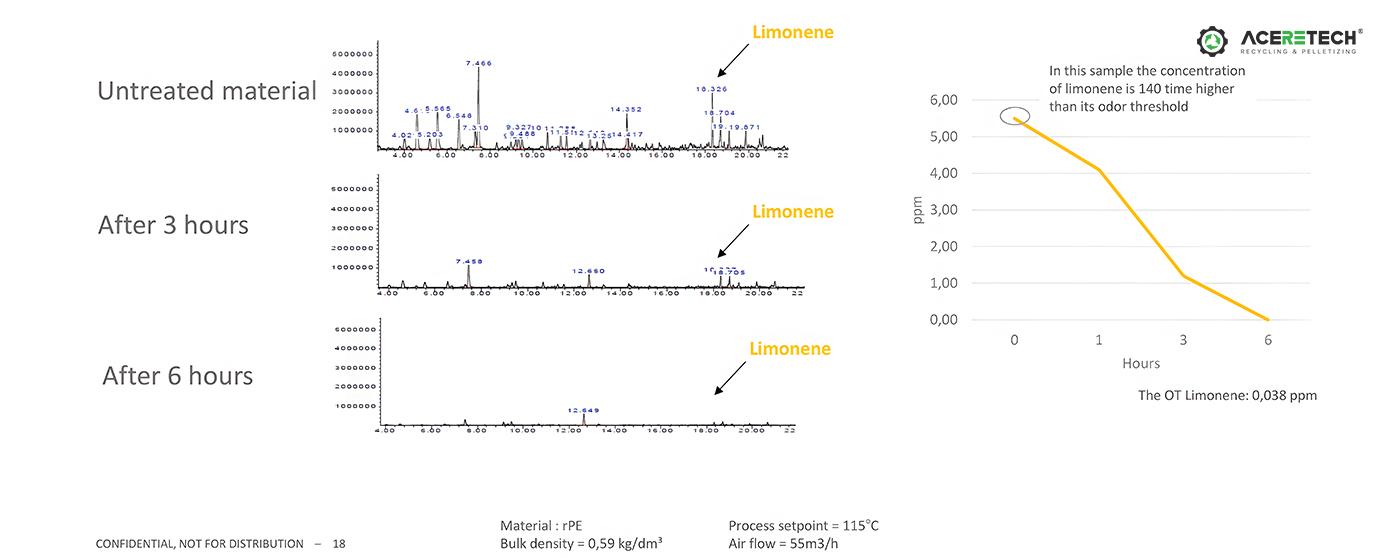

Deodorising Process-Case Study

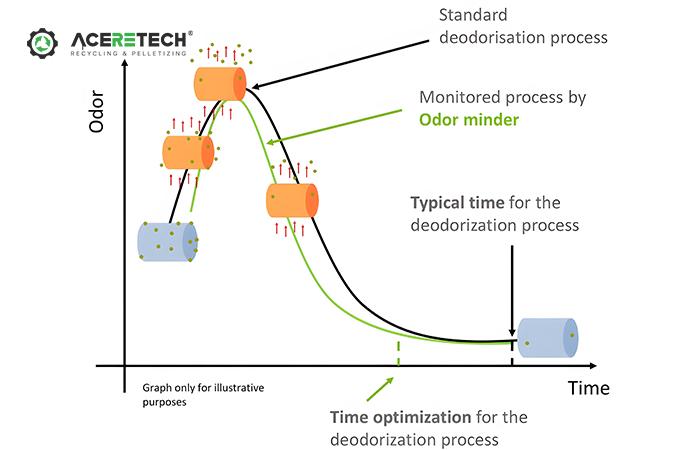

The deodorizing process has been successfully monitored and verified through third-party laboratories.

Odor Minder

The Odor minder is a compact instrument installed directly on hopper and is composed by:

·Auto-sampler pump with the automatic cleaning process

·Dedicated motherboard with 2 ethernet port for communication with PLC and HMI

·Sensors board characterized by:

* High sensitivity and selectivity

* Time stability sensors

* High reactivity to gas presence

Odor minder is a unique and innovative solution that finally gives qualitative information on the odor status of material,driving operators in optimizing the deodorizing process saving time and energy.

Odor Minder

The Odor minder allows monitoring of the different phases during deodorization so the device can help to reduce the residence time in the hopper or avoid the exposition of material to unnecessary heating.

The results are:

Reduced energy consumption

Low thermal stress for recycled resin

Monitoring of inlet raw material

Optimization of the deodorization process

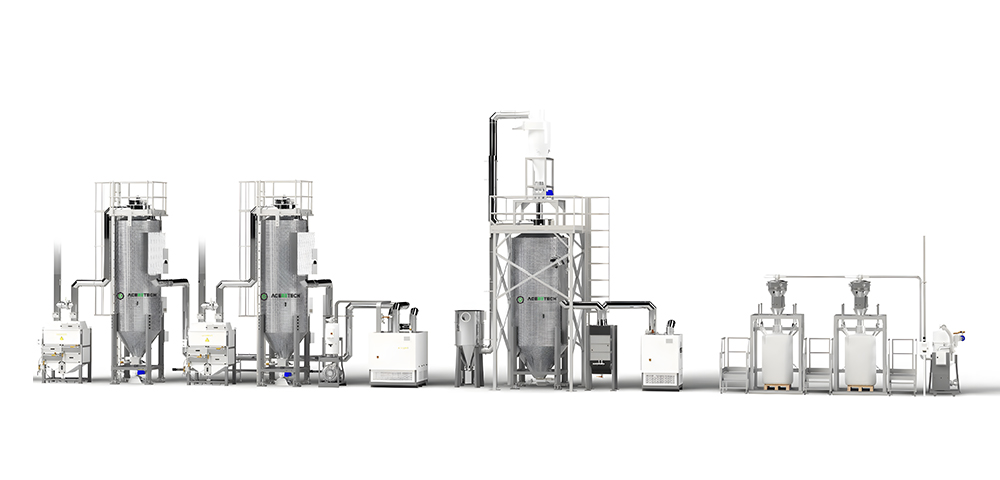

Easypure – Turn Key Solutions

| 1. Easypure | 2. Cooling system | 3. Feeding system |

| The core of the system is the deodorising system; the advanced control can integrate also the feeding system from different sources. |

After the deodorising, a cooling phase can be included to reach the right temperature for the bagging operations |

The feeding system for all the steps can be provided including the intermediate bin, if required |

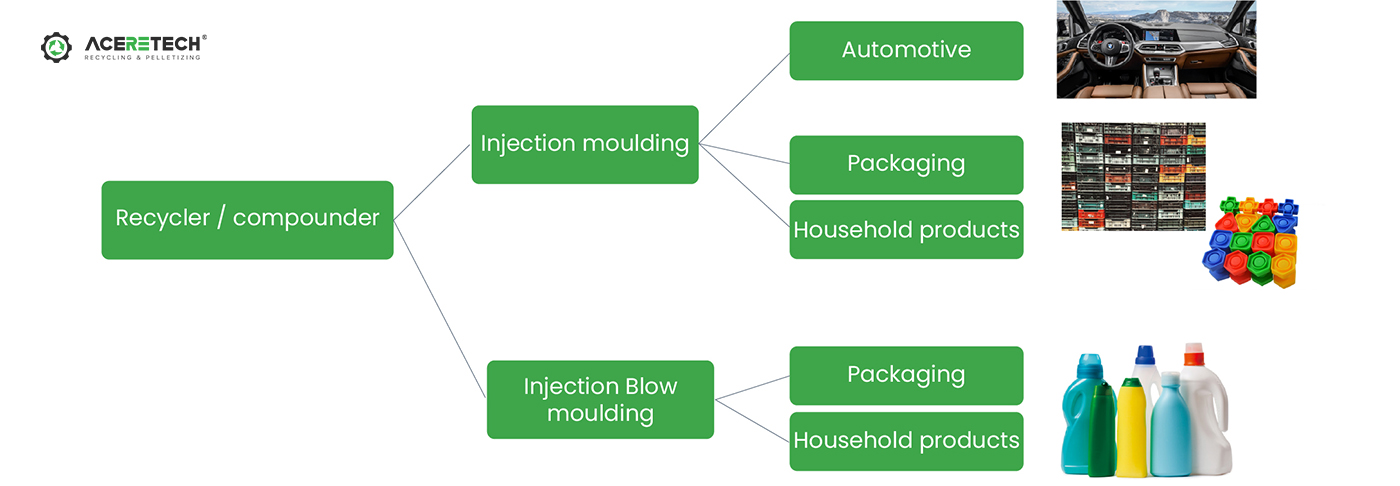

Deodorizer Market Applications

Our Advantages