Executive Summary

Facing the challenges of recycling large-diameter HDPE/PP/PVC waste pipes with diameters up to 1200mm and lengths of 6 meters, traditional recycling methods often encounter problems such as high pre-cutting costs, low efficiency, and high labor risks. The ACERETECH PS series single-shaft large-diameter plastic pipe shredder, with its dual high-power drive and intelligent hydraulic system, achieves "direct feeding and one-step crushing" of ultra-large diameter pipes. This article will delve into the core technological advantages and economic value of this efficient recycling tool.

I. Plastic Pipe Recycling: From "Environmental Burden" to "Green Mine"

Under the wave of the circular economy, the recycling of waste pipes such as HDPE, PP, and PVC has become a lucrative new growth point.

Environmental Compliance: Effectively solves the problem of large-diameter pipes occupying large areas and being difficult to degrade, helping enterprises comply with increasingly stringent global environmental regulations.

High-Value Recycling: After crushing, cleaning, and granulation, waste pipes can be transformed into high-quality recycled granules, which can be directly used in the production of new pipes and packaging containers, significantly reducing reliance on expensive virgin petroleum resources.

Economic Closed Loop: Through an efficient recycling system, the resource turnover rate is improved, transforming municipal waste into a core profit source for enterprises.

II. ACERETECH PS Series: The "Crushing Terminator" Designed for Large-Diameter Pipes

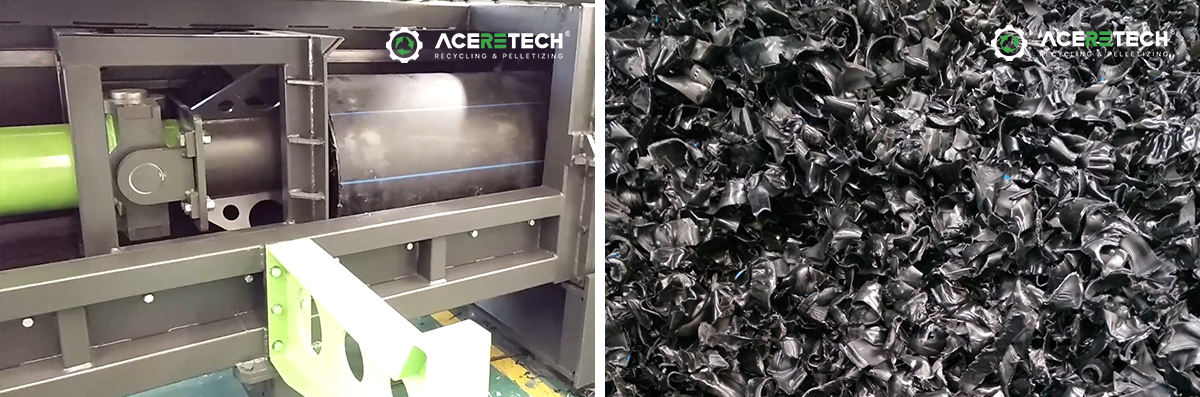

Traditional recycling processes require cutting large pipes with saws or manually, which is time-consuming and labor-intensive. The ACERETECH PS series shredder completely changes this situation.

1. Core Technological Breakthrough: Direct Processing of 1200mm Diameter Pipes

The most significant advantage of the PS series is its ultra-large feeding space. Whether it's a giant pipe with a diameter of 1.2 meters or a single HDPE solid-wall pipe up to 6 meters long, it can be directly fed into the machine without any manual pre-cutting.

2. Excellent Structure and Performance: Built for Extreme Working Conditions

Dual-Drive Powerful Motor: Equipped with dual high-power motors (up to 2x55 kW), generating ultra-high torque to easily shred high-strength materials. Integral Forged Rotor: The PS800/1000/1500 model rotors utilize a high-strength integral forging process and undergo precision balancing to ensure no deformation or breakage under heavy-duty operation.

Intelligent Four-Corner Blade System: The special four-corner moving blade design requires only changing the cutting angle after wear, extending the service life by four times. The precise 0.5mm fixed blade gap ensures uniform output, providing ideal raw materials for subsequent processes.

3. Fully Automatic Control: Siemens PLC and Hydraulic Feeding

High-Efficiency Hydraulic Feeding: Equipped with a Taiwanese brand hydraulic system, it intelligently senses the load and smoothly feeds the pipes, effectively preventing jamming caused by excessive feeding speed.

Intelligent Human-Machine Interaction: Using Siemens/WEG motors and intelligent PLC programming, operators only need one-button start and stop to achieve fully automatic closed-loop operation, greatly reducing labor costs.

III. From Single Machine to Complete Line: ACERETECH Comprehensive Turnkey Solutions

The PS series single-shaft shredder is just the starting point for efficient recycling. ACERETECH provides a one-stop integrated system from crushing and cleaning to granulation:

Pre-crushing: PS series shredders convert large pipes into primary fragments.

Intermediate Washinging: Removes impurities and improves the purity of recycled materials.

Post-pelletizing: Produces high-performance recycled granules through ACERETECH's leading single/twin-screw granulators.

Conclusion: Upgrade Your Recycling Line with ACERETECH

If you are looking for ways to improve your waste plastic pipe processing capacity and reduce operating costs, the ACERETECH PS series single-shaft large-diameter pipe shredder is undoubtedly your best choice. It is not just a machine, but a powerful tool to keep you ahead in the circular economy race.

Take Action Now

Want to learn about PS series operating cases in your area or get a detailed quote?

👉 Click to visit the ACERETECH official website.

📩 Contact our technical experts to get a customized solution!

Frequently Asked Questions about Large-Diameter Plastic Pipe Shredding (FAQ)

Q1: Can the PS series shredder really process 1200mm pipes without any pre-cutting?

A: Yes. Traditional shredders require manual cutting of large-diameter pipes due to limitations in their feed hoppers. The ACERETECH PS series is specifically designed for large-diameter pipes, featuring an ultra-wide chamber structure and heavy-duty hydraulic pusher, allowing direct feeding of pipes up to 1200mm in diameter and 3-6 meters in length, significantly saving on labor and additional cutting equipment costs.

Q2: Is the blade durable when this high-power shredder processes high-toughness plastics (such as HDPE, PP)?

A: For high-toughness materials, we use a special four-corner rotating blade design. This blade material undergoes deep heat treatment and has extremely high wear resistance. Most importantly, when one cutting edge is worn, you can directly rotate the blade head to use the other three edges, meaning the lifespan of a single set of blades is four times that of ordinary blades, significantly reducing subsequent maintenance costs.

Q3: How does the equipment prevent jamming or motor burnout when processing hard or extra-thick pipes?

A: The ACERETECH PS series is equipped with an intelligent PLC control system. When the system detects rotor overload or excessive pressure, the hydraulic pusher will automatically stop pushing or even retract, and the rotor will automatically reverse to adjust the material position. Combined with high-performance motors from brands such as Siemens/WEG, this effectively prevents jamming risks and protects the electrical system.

Q4: Can the output size of different PS series shredder models be adjusted?

A: Yes. The size of the output particles is mainly determined by the screen mesh size at the bottom of the equipment. We will customize screens with different mesh sizes according to the customer's subsequent processes (such as direct cleaning or entering a secondary crusher). In addition, the gap between the rotating and stationary blades can be precisely adjusted to 0.5mm, ensuring consistency in output size.

Q5: If I purchase a single machine, is it easy to upgrade to a fully automatic recycling production line later?

A: It's very convenient. The PS series shredder is designed with interfaces for connecting to other equipment. You can add belt conveyors, metal detectors, secondary crushers, and complete washing and granulation lines to the downstream process as needed. ACERETECH provides modularly designed "turnkey" solutions that support seamless production line upgrades as businesses expand.