Abstract: PA (nylon) film is widely used in high-end packaging due to its excellent physical properties. However, its thinness and flexibility present three major pre-processing challenges for recycling: entanglement, wrapping, and slippage. This article will delve into the necessity and technical challenges of PA film recycling, and focus on how Aceretech's LS series single-shaft shredder, with its unique design, becomes an ideal choice for solving the PA film shredding problem, providing stable and uniform high-quality raw materials for downstream recycling processes.

Introduction: The Difficulty of Recycling High-Value PA Films

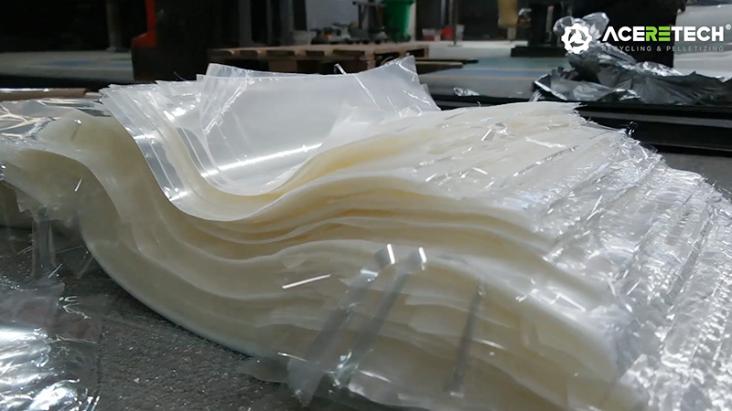

PA (polyamide, commonly known as nylon) film, with its excellent tensile strength, puncture resistance, high and low temperature resistance, and excellent barrier properties, has become the preferred material in high-end fields such as food packaging (e.g., retort pouches, frozen packaging), medical supplies, and protective films for electronic components. However, the recycling path for these high-performance films after they complete their life cycle is exceptionally difficult.

Compared to common PE or PP films, PA films are thinner, tougher, and more elastic. These advantages, however, become significant challenges in the recycling process. In traditional shredders, PA films easily entangle on the cutter shaft and bearings, causing frequent downtime; their smooth surface causes materials to slip within the shredding chamber, making them difficult to grip and shear effectively; and their high toughness places higher demands on the shearing force of the blades. These problems directly lead to low PA film recycling efficiency and high operating costs, deterring many recycling companies and resulting in a waste of valuable resources.

Part 1: Why Must We Emphasize PA Film Recycling?

Despite the difficulties of recycling, promoting PA film recycling has undeniable economic and environmental value.

* Environmental Value: Reducing Ecological Burden

* Reducing Landfill Pressure: PA films are extremely difficult to degrade in the natural environment, and landfilling occupies valuable land resources for a long time.

* Avoiding Incineration Pollution: Incinerating PA films produces harmful gases such as nitrogen oxides, causing secondary pollution to the atmosphere.

* Conserving Primary Resources: PA production relies on non-renewable resources such as petroleum. Recycling one ton of PA film means saving several tons of petroleum resources and significantly reducing carbon emissions during production.

* Economic Value: Unearthing an "Urban Mine"

* High Recycling Value: As an engineering plastic, recycled PA granules have performance far superior to ordinary polyolefins and can still be used to produce high-performance industrial components, such as automotive parts, electronic casings, and industrial filaments, resulting in higher market value.

* Reduced Production Costs: For manufacturers using PA film, establishing a closed-loop recycling system to recycle scraps and waste can directly reduce raw material procurement costs and enhance competitiveness.

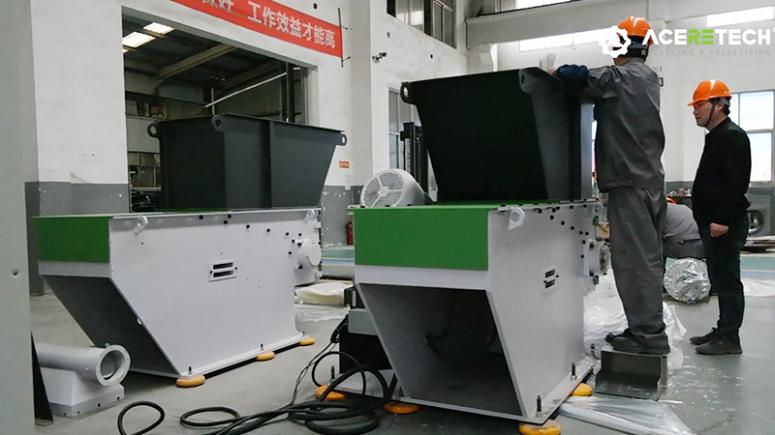

Facing the pre-processing bottleneck in PA film recycling, Aceretech's LS series single-shaft shredder offers a precise and efficient solution. It doesn't simply "shred" the material; instead, through a series of ingenious designs, it specifically overcomes the three major challenges of PA film "entanglement, wrapping, and slippage."

1. Unique Anti-Tangle Design, Say Goodbye to the "Downtime Nightmare"

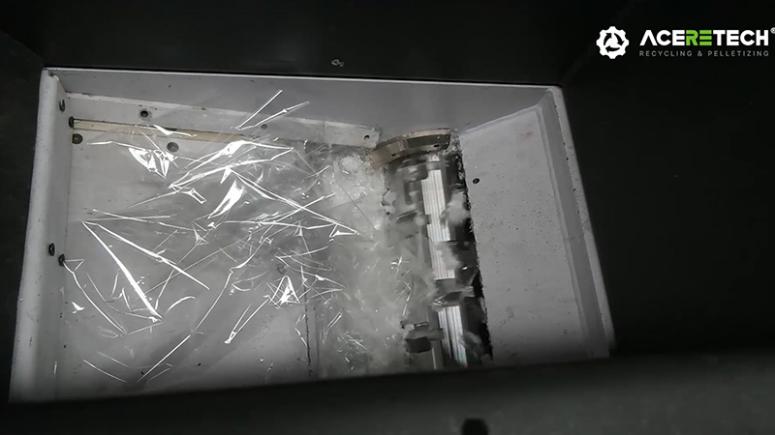

Problem: When processing film in traditional shredders, the material tends to become tightly entangled on the main shaft like a ball of yarn, eventually leading to motor overload and equipment jamming.

LS Series Solution: The LS series employs an optimized V-shaped or hexagonal rotor cutter holder design. This structure effectively disrupts the continuous entanglement of the film. Combined with a reverse automatic unloading function, when encountering entanglement or overload, the cutter shaft automatically reverses to push out the entangled material and then resumes forward rotation. This intelligent design fundamentally solves the problem of frequent downtime caused by entanglement, ensuring continuous production.

2. Powerful Grip and Efficient Shearing, Solving the "Slippage" Problem

Problem: The smooth surface of PA film makes it difficult to hold within the shredding chamber, causing the cutters to idle and resulting in extremely low shredding efficiency.

LS Series Solution: The core advantage of the LS series shredder lies in the coordinated operation of its pusher box and cutters. The hydraulically driven pusher box uses a powerful, constant thrust to press the fluffy PA film material against the rotating cutter shaft. This "active feeding" method ensures the material is firmly "grabbed," preventing slippage. Simultaneously, high-speed European standard blades use powerful shearing force to instantly shred the compressed PA film into uniform small pieces, achieving highly efficient processing.

3. Compact Design and Intelligent Control for Improved Operational Efficiency

Problem: Large equipment occupies a lot of space and consumes a lot of energy, making it uneconomical for PA film recycling scenarios with relatively small processing volumes.

LS Series Solution: The LS series is known for its small size and high output. Its compact design is ideal for factories with limited space or as primary crushing equipment in recycling lines. Furthermore, the equipped Siemens PLC intelligent control system is not only easy to operate but also monitors the equipment's operating status in real time, providing overload protection and ensuring safe, stable, and low-energy operation.

Conclusion: Choosing the LS series unlocks the door to high-value PA film recycling.

PA film recycling is not an unsolvable problem; the key lies in finding the right pretreatment tools. Aceretech's LS series single-shaft shredder, with its anti-winding design, powerful feeding system, high-efficiency shearing capacity, and compact, intelligent overall structure, precisely solves the most troublesome pre-processing stage in PA film recycling.

It's not just a shredder; it's a "golden key" to entering the high-value engineering plastics recycling field. It transforms troublesome PA film waste into high-quality raw materials readily accepted by downstream washing and granulation production lines, helping you translate environmental responsibility into tangible economic benefits in the wave of the circular economy.

Click the link below to view a video of the PA film shredder in operation at the factory: