With growing environmental awareness and the advancement of the circular economy, the use of synthetic fiber materials such as PET (polyester) and PA (nylon) is becoming increasingly widespread, and the recycling and reuse of these waste materials has become a focus of industry attention. However, the recycling and pelletizing of PET/PA fabric, fibers, and filaments is not an easy task, and traditional processes often face numerous challenges. Against this backdrop, ACERETECH's DTS series plastic shredders and their innovative friction agglomeration technology provide an ideal solution for efficient and cost-effective PET/PA fabric/fiber/filament recycling and pelletization.

Common Problems in PET/PA Fabric/Fiber/Fiber Recycling

ACERETECH DTS Series Shredder: A Front-End Guarantee for Efficient Shredding

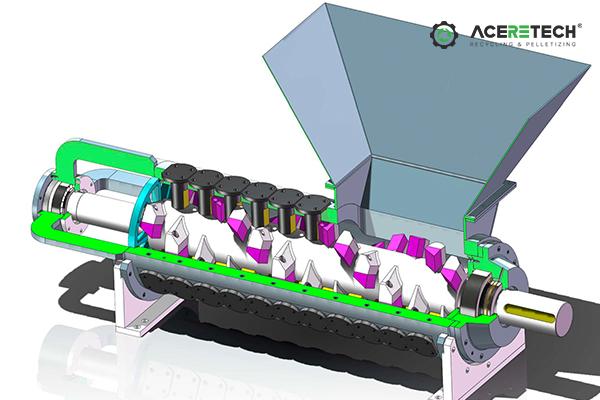

The ACERETECH DTS Series plastic shredder was developed to address the front-end shredding challenges in PET/PA fabric/fiber/filament recycling. This equipment is specifically designed for processing flexible materials.

When recycling PET/PA fabric, fibers, and filaments, companies often encounter the following challenges:

* Complex material form and difficult pre-treatment: Fabric, fiber bundles, and filaments are typically large, loose, or highly flexible. Direct pelletization can easily cause entanglements and blockages, impacting the continuous and stable operation of the equipment. High melt viscosity and high processing energy consumption: Both PET and PA have high melt viscosities. Traditional pelletizing processes typically require high melt temperatures, which not only results in significant energy consumption but can also cause material degradation at high temperatures, impacting the quality of the recycled pellets.

* Poor dispersion and difficulty ensuring pellet uniformity: Inadequately shredded fibers or filaments are difficult to evenly disperse during the melt process, resulting in uneven pellet sizes and even defects such as fisheyes, which impact subsequent processing performance.

* Cost pressure and need for improved economic efficiency: Traditional recycling processes are lengthy, energy-intensive, and require significant equipment maintenance, resulting in high production costs for recycled pellets and weakening their market competitiveness.

Conveyor Belt

Conveyor Belt Width Approximately 800mm: The spacious conveyor belt easily accommodates and stably conveys large pieces of fabric, fiber bundles, or filaments, ensuring uniform and continuous material delivery to the shredder chamber, effectively preventing material accumulation or uneven loading.

Conveyor Belt Motor Power 3.0KW: The powerful and stable power source ensures reliable operation of the conveyor belt under varying load conditions, providing a continuous material supply to the shredder.

Conveyor Belt Base Material PVC: PVC (polyvinyl chloride) conveyor belts offer excellent wear resistance, flexibility, and corrosion resistance, adapting to the characteristics of a variety of recycled materials, ensuring efficient and durable conveying, and reducing maintenance frequency.

DTS Series Shredder

The DTS series shredder uses the powerful shearing action between sharp rotating blades and fixed fixed blades to initially shred large pieces of PET/PA fabric, fiber, and filament into smaller fragments, laying an excellent foundation for the subsequent granulation process and effectively solving the problems of complex material forms and difficult pre-processing.

Friction Agglomerator

Friction Agglomeration Technology: The Core of Energy-Saving and High-Efficiency Pelletization

After shredding, ACERETECH innovatively utilizes the Friction Agglomerator technology, which is the core of this equipment's low-cost, high-quality pelletization. Its operating principle is unique:

No external heating, mechanically heated softening: The key to friction agglomeration technology is the absence of additional heating. The rotor within the equipment rotates at high speed, generating intense mechanical friction with the PET/PA chips being processed. This friction generates significant heat within the material, raising its temperature and softening it below its actual melting point.

Instant Bonding and Extrusion: Once the material softens, the powerful shear and pressure of the rotor cause the softened surfaces to contact, instantly bonding and fusing. Simultaneously, the molten material is continuously pushed toward the die opening and extruded through a custom-shaped die to form continuous strands.

Crusher

Crushing into Regular Pellets: The extruded strands then enter a crusher for crushing and precise cutting into pellets of the customer's desired size.

Advantages of Friction Agglomeration Technology

ACERETECH's friction agglomeration technology offers the following significant advantages over traditional pelletizing processes:

Significantly Reduced Energy Consumption: Relying solely on mechanical friction to generate heat, eliminating the need for additional heating, significantly reduces electricity consumption and directly lowers production costs.

Reduced Material Degradation: Softening the material at a temperature below its actual melting point effectively avoids oxidation and degradation caused by high temperatures, ensuring the high performance and purity of the recycled pellets.

Simplified Process Flow: Efficiently integrating shredding, softening, extrusion, and crushing processes shortens the production process and improves efficiency.

Excellent Pellet Quality: Because the material is fully fused in its softened state, the final pellets are dense and uniform, with no noticeable unmelted fibers, making them suitable for various subsequent processing requirements, such as spinning and injection molding.

Conclusion

The recycling and pelletizing of PET/PA fabrics, fibers, and filaments is a crucial step in achieving a circular economy. The ACERETECH DTS series plastic shredder, combined with its unique friction agglomeration technology, successfully addresses many of the pain points of traditional recycling methods through efficient front-end crushing and an innovative, energy-saving granulation process. This provides an efficient, low-cost, and high-quality green path for the resourceful utilization of PET/PA waste. This not only helps companies reduce production costs and enhance market competitiveness, but also contributes significantly to the sustainable development of the textile and plastics industries. Choosing ACERETECH solutions means choosing a smarter, more environmentally friendly, and more cost-effective recycling future.