In the wave of the circular economy for plastics, the high-value and efficient recycling of waste plastics has become a core driving force for industry development. Aceretech, a leading global manufacturer of plastic recycling and granulation equipment, deeply understands the diverse needs of different customers and materials. Therefore, we have meticulously designed the powerful and widely applicable ACS series pelletizers, including the ACS-H single-stage complete line, the ACS-Pro high-precision complete line, and the ACSS double-stage complete line, providing you with a one-stop recycling solution from basic to advanced.

Whether you are processing loose films, clean bottle flakes, or engineering plastics containing impurities or requiring high purity, the Aceretech ACS series can help you transform waste into valuable resources and maximize value.

The ACS-H series is our most popular basic high-efficiency solution, designed for recyclers seeking high capacity and low operating costs. It is especially adept at processing various loose and tangled plastic films and soft packaging, making it an ideal choice for recycling lightweight materials such as woven bags, jumbo bags, and agricultural films.

Key Advantages:

* Single-stage integrated design, simplified process: Innovatively integrates crushing, extrusion, and pelletizing into one process, significantly shortening the production process and effectively reducing equipment footprint and initial investment costs.

* Powerful dewatering, ready for immediate use: Equipped with a high-efficiency screw extruder and a water-ring hot-cutting system, it separates moisture from the material during extrusion, ensuring extremely low moisture content in the produced granules, which can be directly packaged or used in the next process.

* Intelligent control, stable and reliable: Adopts an advanced PLC touch screen control system with an intuitive interface and convenient operation, allowing real-time monitoring of various production parameters to ensure the stability and high efficiency of the production process.

* Wide application, high cost-effectiveness: Optimized for the recycling of lightweight, high-volume materials such as PE/PP films, jumbo bags, non-woven fabrics, and carpet materials, it is a cost-effective choice for quickly starting a recycling business.

The ACS-Pro is our newly developed high-precision recycling system, designed specifically for producing high-quality, high-value recycled granules. With its superior exhaust (degassing) and high-precision filtration performance, it can perfectly handle complex and highly contaminated materials, ensuring the output of stable and reliable high-quality plastic granules.

Key Advantages:

* Excellent Exhaust, Pure and Odorless: Equipped with a dual vacuum exhaust system, it efficiently removes moisture, volatile organic compounds (VOCs), and odors from molten plastic, fundamentally guaranteeing the purity of the granules.

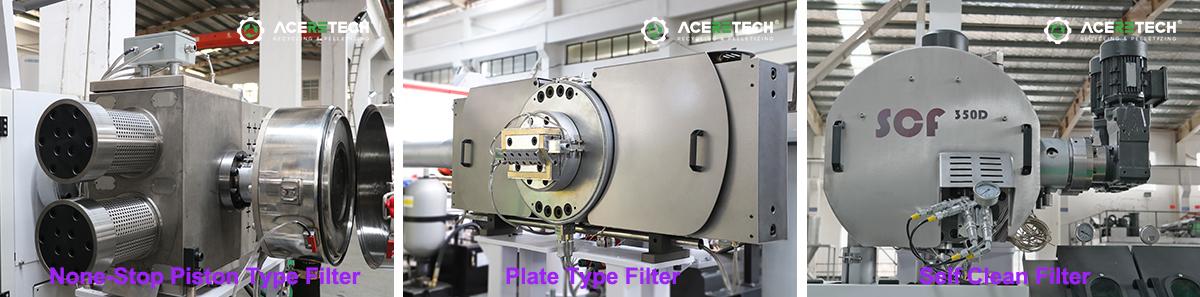

* High-Precision Filtration, Superior Quality: Featuring a new SCF self-cleaning filtration system, it can precisely filter up to 5% of contaminants in the melt flow, effectively removing tiny impurities and gels, resulting in granules with excellent gloss and mechanical properties.

* High-Value Output, Wide Application: The produced granules have high density, uniform color, and strong stability, and can be directly used in food-grade, medical-grade, or high-transparency recycling applications, helping you maximize profits.

* Handles Demanding Materials, Leading Technology: Particularly suitable for processing PET flakes and filaments, PA/PU waste, PVB interlayer films, and complex mixtures with masterbatches or color concentrates, making it a wise investment for technologically advanced companies.

The ACSS series adopts a two-stage design, making it a stable and durable choice for processing complex and difficult-to-process materials. This system consists of two single-screw extruders connected in series, perfectly handling various materials with high ink content, high moisture content, poor fluidity, temperature sensitivity, and high impurity content, ensuring a stable and controllable production process.

Key Advantages:

* Stable Structure, Convenient Maintenance: The separate design allows the extruder and pelletizer to operate independently, making maintenance easier and allowing for flexible replacement of the pelletizing system according to different materials, reducing downtime.

* Strong Adaptability, Wide Processing Range: It can handle clean, dry PET bottle flakes, sheets, and filaments, as well as materials containing small amounts of impurities. It excels in the recycling of engineering plastics (such as ABS, PC, HIPS) and the processing of rigid plastic regrind.

* Flexible pelletizing methods to meet diverse needs: Depending on material characteristics and customer requirements, you can flexibly choose water-ring pelletizing, strand pelletizing, or underwater cutting to produce granules of different shapes (round, strip), meeting the requirements of various downstream processes such as film blowing, injection molding, and pipe manufacturing.

* High output and durability, built to last: The heavy-duty design of the screw and barrel ensures excellent stability and an extra-long service life under long-term, high-load operation, providing reliable assurance for large-scale production.

Comparison Table

| Feature Comparison |

ACS-H Single-Stage Line |

ACS-Pro High-Precision Line | ACSS Double-Stage Line

|

| Core Process |

Integrated Single-Stage |

Integrated High-Precision Single-Stage | Separate Double-Stage |

| Main Advantages | Efficient and economical | High purity, high added value | Stable, durable, and versatile |

| Applicable Materials | PE/PP film, jumbo bags, flexible packaging | PET/PA/PVB/high-demand waste materials | PET/PP sheets, filaments, engineering plastics |

| Pellet Quality | Good, meets general requirements | Excellent, close to virgin material | Stable, meets various requirements |

| Ideal Applications | Woven bags, garbage bags, filler masterbatch | High-transparency sheets, food packaging, injection molding | Fibers, sheets, general injection molding |

IV. Conclusion

The Aceretech ACS series granulator is not just a simple piece of equipment, but a customized plastic recycling value enhancement system tailored for you. Whether you are a startup company seeking cost-effective entry-level solutions or an established enterprise pursuing superior quality and market leadership, we can provide the most suitable technical support.

Contact us today for a free production plan assessment and customized quote, and let Aceretech's professional technology help your plastic recycling business reach new heights!

FAQ

Q1: How do I choose between ACS-H, ACS-Pro, and ACSS based on my type of waste plastic?

A: The selection mainly depends on the cleanliness and impurity content of the material:

ACS-H is best suited for relatively clean PE/PP soft packaging (such as films and woven bags), pursuing ultimate cost-effectiveness and space utilization.

ACS-Pro is designed for applications requiring high purity, no odor, and high transparency (such as PET bottle flakes, PA waste), and is equipped with a top-of-the-line degassing and self-cleaning filtration system.

ACSS is the preferred choice for processing highly contaminated, heavily inked, high-moisture, or heat-sensitive materials (such as ABS/PC regrind, films with heavy impurities), and its dual-stage design ensures more stable melt pressure.

Q2: How does the Aceretech ACS series handle high moisture content in materials?

A: Our equipment employs multiple dewatering solutions. Through innovative integrated crushing and extrusion technology and efficient screw design, physical dewatering can be achieved at the front end of the extruder. It is also equipped with a dual vacuum degassing system, which effectively removes moisture and volatile organic compounds (VOCs) from the molten state, ensuring that the final granule moisture content is less than 1%, enabling "immediate use after production."

Q3: What are the advantages of the SCF self-cleaning filtration system?

A: Compared to traditional screen changers, the SCF self-cleaning filtration system can handle heavily contaminated melts with impurity content up to 5%. It eliminates the need for frequent screen changes and allows for fully automatic slag removal. This not only significantly reduces consumable costs but also ensures constant melt pressure, thereby significantly improving the mechanical properties and visual gloss of the recycled granules.

Q4: Is the dual-stage (ACSS) granulator more durable than the single-stage (ACS-H)?

A: The ACSS dual-stage system does indeed exhibit a longer service life when processing engineering plastics or materials containing impurities. This is because it distributes the plasticizing and granulation processes across two extruders, sharing the load and wear on the screws. Furthermore, the pelletizing method can be changed between the two stages as needed, offering significant advantages in production flexibility and heavy-duty continuous operation.

Q5: Can Aceretech provide customized granulation solutions for specific materials?

A: Yes. Aceretech provides a full range of customized services, from material testing to production line design. We can adjust the screw length-to-diameter ratio, filtration accuracy, and pelletizing method (water ring, strand, or underwater cutting) based on your finished granule application (such as film blowing, injection molding, or pipe grade), helping you maximize profits with the lowest energy consumption.