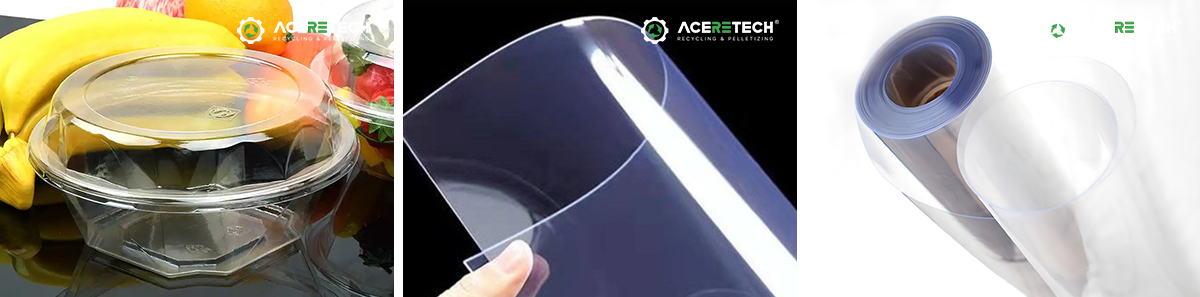

In today's era of pursuing sustainable development and food safety, food-grade PET sheet, as an important packaging material, is playing an increasingly critical role. So, what is PET sheet? What are its wide applications?

Ⅰ. Definition and application of PET sheet

PET, or polyethylene terephthalate, is a common thermoplastic. PET sheet is a sheet of PET resin with a specific thickness and size processed by extrusion and other processes. This sheet has excellent transparency, good toughness, chemical corrosion resistance and certain heat resistance, making it shine in the field of food packaging. From the beverage bottles and yogurt cups we drink daily, to the food trays that need to show the appearance, to the lunch boxes used for microwave heating, PET sheets are everywhere, providing convenient, safe and beautiful packaging solutions for food.

II. ACERETECH: Leading a New Era of Food-Grade R-PET Recycling Extrusion

ACERETECH is a global leader in manufacturing advanced equipment for food-grade recycled PET (R-PET) processing. As the only manufacturer in China to earn U.S. FDA certification for its food-grade PET recycling extrusion lines, ACERETECH demonstrates unparalleled technical expertise and commitment to quality. This prestigious certification underscores the company’s dedication to ensuring food safety and delivering reliable, high-performance recycling solutions.

Specializing in plastic recycling equipment, ACERETECH offers comprehensive turnkey solutions for food-grade R-PET waste recycling. From initial washing to extrusion and granulation, ACERETECH’s cutting-edge systems enable businesses to efficiently transform PET waste, including high-quality washed PET bottle flakes, into food-grade PET materials in a streamlined, one-step process. These solutions optimize resource utilization, reduce production costs, and support environmental sustainability by promoting a circular economy.

III. Precision process flow, casting excellent quality

ACERETECH's food-grade PET recycling extrusion line adopts a rigorous and efficient process flow to ensure that each roll of sheet meets the highest standards:

Vacuum feeder: ensures that the raw materials (cleaned PET bottle flakes or PET particles) can be cleanly and evenly delivered to the production line.

Reaction chamber: provides a stable environment for the subsequent extrusion process.

ACS single screw extruder: core component, its unique design can efficiently and evenly melt and plasticize PET raw materials to ensure stable material performance.

Backwash screen changer: clean the filter without stopping the machine, remove possible impurities, ensure the purity of the melt, and prevent blockage.

Melt pump: provides stable and accurate melt pressure and flow, laying a solid foundation for subsequent molding.

Online melt viscosity measurement system: real-time monitoring of melt viscosity to ensure the consistency of product quality, which is a key control point for food-grade materials.

T-die head: extrude the molten PET evenly to form a sheet melt of the required width and thickness.

Three-roll calender: precisely cool and compact the extruded sheet to make it uniform in thickness and smooth on the surface.

Trimming device: removes possible defects or irregularities on the edge of the sheet to ensure the regularity of the finished product.

Silicone oil coating device: applies a thin layer of silicone oil on the surface of the sheet to facilitate subsequent winding and processing and prevent adhesion.

Traction device: traction of the sheet through the entire production line at a constant speed.

Winder: neatly winds the final food-grade PET sheet into rolls for easy storage and transportation.

This series of precise process links are closely linked to ensure the high quality and food-grade safety of the final product.

Ⅳ. The PET sheet market has broad development prospects

With the increasing global awareness of environmental protection and the in-depth promotion of the concept of circular economy, the demand for the use of recycled materials to produce food packaging is growing rapidly. Food-grade R-PET sheets not only effectively reduce dependence on virgin petroleum resources and reduce carbon emissions, but also occupy an increasingly important position in the food packaging market due to their excellent performance and cost advantages. Consumers' concerns about food safety and sustainable packaging have further promoted the prosperity of this market. It can be foreseen that in the future, food-grade PET sheets, especially R-PET sheets produced with advanced recycling technology, will continue to play a core role in the packaging industry, and the market prospects are very broad.

In summary, ACERETECH, with its FDA-certified advanced food-grade R-PET recycling extrusion line, not only provides high-quality and environmentally friendly solutions for the food packaging industry, but also demonstrates the strong strength of Chinese manufacturing in the field of high-end plastic recycling equipment, and is leading the industry towards a greener and safer future.

Food-grade PET Sheet Extrusion: Environmentally Friendly and Safe Future Packaging Options

2025/06/26