Article Paragraphs:

I. Challenges and Opportunities in Rigid Plastic Recycling

II. Core Equipment of Rigid Plastic Recycling Machines

III. Industry Applications of Rigid Plastic Recycling Machines

IV. Future Technological Innovation of Rigid Plastic Recycling Machines

In today's era of increasing environmental awareness, the recycling and reuse of rigid plastics has become an important way to reduce environmental pollution and conserve resources. As a key piece of equipment in this process, the rigid plastic recycling machine transforms waste rigid plastics into reusable recycled pellets through a series of processes including shredding, crushing, washing, and pelletizing. This article will delve into the core functions, technological processes, and important role of rigid plastic recycling machines in promoting sustainable development.

I. Challenges and Opportunities in Rigid Plastic Recycling

Rigid plastics such as polyvinyl chloride (PVC), polypropylene (PP), and polyethylene (PE) are widely used in construction, packaging, automotive, and electronics industries due to their excellent physical properties. However, if these durable materials are not properly handled after their life cycle, they will become a long-term environmental burden. Traditional landfilling or incineration methods not only consume land resources but also release harmful substances, causing secondary pollution to soil, water, and the atmosphere.

To address this challenge, rigid plastic recycling technology has emerged. By using specialized equipment to convert waste rigid plastics into recycled pellets, not only can the consumption of virgin plastics be reduced, and dependence on petroleum resources decreased, but environmental pressure can also be significantly alleviated. Studies show that recycling one ton of plastic can save approximately 3-4 tons of petroleum resources and reduce carbon dioxide emissions by approximately 2.5 tons. Rigid plastic recycling machines are the key tools for achieving this green cycle.

II. Core Equipment of Rigid Plastic Recycling Machines

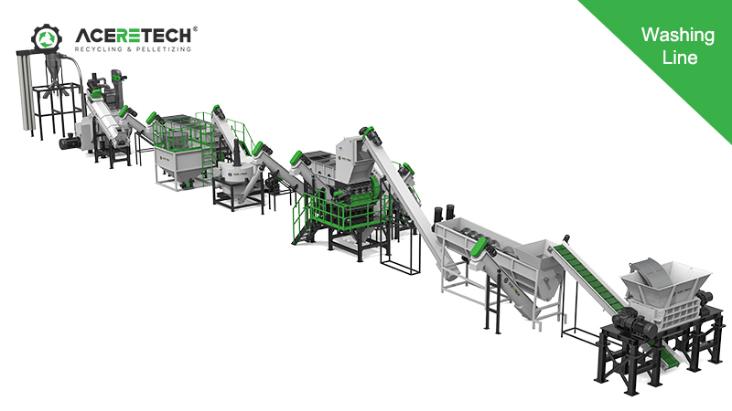

A rigid plastic recycling machine is not a single piece of equipment but a system composed of various specialized machines. Its core functions cover the entire process from raw material pretreatment to finished pellet production. This system typically includes main units such as shredders, crushers, washing equipment, dewatering equipment, and pelletizers. These units work together to ensure the efficiency and environmental friendliness of the recycling process.

1. Shredder: The First Step in Recycling Rigid Plastics

For large, irregularly shaped, or difficult-to-shred rigid plastics, such as large containers, pipes, and sheets, shredders can break them down into smaller fragments, creating conditions for subsequent processing. The working principle of a shredder is mainly to use high-speed rotating blades to shear, tear, and compress the plastic, breaking down large pieces into smaller ones. This process not only improves processing efficiency but also reduces energy consumption because smaller pieces are easier to crush and clean later.

Modern shredders are typically equipped with adjustable blades and feeding systems to accommodate plastics of varying hardness and toughness. For example, for tougher materials like PVC pipes, shredders require greater shearing force and sharper blades; while for relatively brittle materials like PP sheets, higher-speed blades can achieve rapid decomposition. The size of the shredded material is typically controlled between 50-100mm, a size that facilitates transportation and storage and provides ideal feeding conditions for subsequent crushing.

2. Crusher: Refined Material Processing

Building upon shredding, the crusher further refines the material. Compared to shredders, crushers produce more uniform and smaller particles, typically between 5-30mm, creating more favorable conditions for subsequent washing and pelletizing. The working principle of a crusher mainly falls into two types: one uses high-speed rotating blades in conjunction with fixed blades to crush materials through shearing and impact; the other uses toothed discs or hammers to impact and crush the material.

The fully automatic plastic crusher, as the core equipment in the crushing process, typically consists of a feeding system, a crushing system, a screening system, and a discharge system. The feeding system evenly feeds the shredded plastic into the crushing chamber; the high-speed rotating blades in the crushing system work in conjunction with fixed blades to shear and impact the plastic; the screening system uses screens to control the size of the crushed particles, ensuring output quality; finally, particles meeting the requirements are discharged through the outlet. This automated process not only improves processing efficiency but also ensures the uniformity of particle size, laying the foundation for the stability of subsequent processes.

The advantage of crushers lies in their powerful processing capacity, capable of handling several tons of material per hour, and their high degree of automation, significantly reducing labor costs. For rigid plastics, another important function of crushers is their ability to process plastic waste mixed with foreign objects such as metal and glass. A screening system separates most of the impurities, improving the efficiency of subsequent washing.

3. Washing: A Key Step in Removing Contaminants

Washing is a crucial step in the recycling process of rigid plastics, directly affecting the final quality of the recycled pellets. Shredded and broken plastic fragments often contain contaminants such as oil, dust, labels, and adhesives. If not thoroughly removed, these contaminants not only affect the appearance and performance of the recycled pellets but may also disrupt the normal operation of subsequent processing equipment. Therefore, a complete washing system typically includes pre-washing, soaking, rinsing, friction washing, and dewatering.

Pre-washing mainly removes larger impurities such as dirt, stones, and paper, usually through manual sorting or mechanical screening. The soaking stage involves placing the plastic fragments in a washing tank with appropriate amounts of washing agent and water to soften and dissolve the dirt and residue on the plastic surface. The stirring and washing process enhances the washing effect through mechanical agitation, allowing the washing agent to better contact the plastic surface. The rinsing and scrubbing stages use clean water to remove residual washing agent and dirt. Finally, a centrifuge or dewatering machine removes moisture from the plastic.

It is worth noting that the washing process generates a large amount of wastewater containing washing agents, dirt, and residues. Improper treatment can cause secondary pollution. Therefore, modern rigid plastic recycling systems are typically equipped with wastewater treatment units. Through processes such as physical filtration, chemical flocculation, and biodegradation, the wastewater meets discharge or reuse standards, achieving clean production.

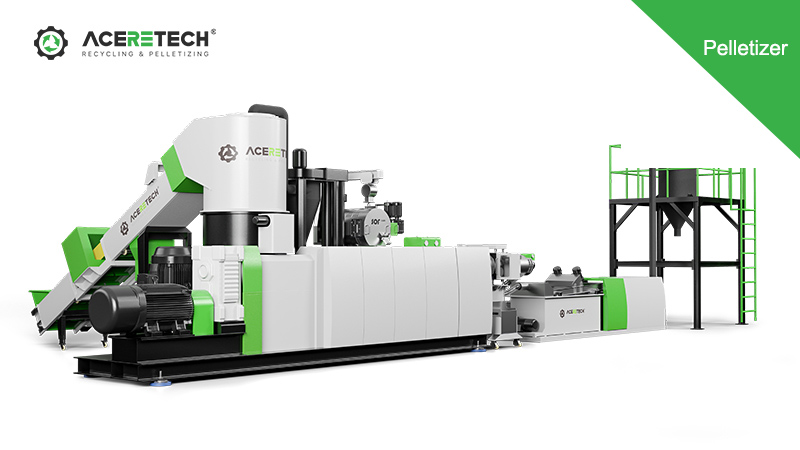

4. Granulator: The Final Transformation in the Recycling Process

After the preceding processes, the clean plastic fragments enter the final stage—pelletizing. The granulator melts the plastic fragments into a uniform melt through heating and the shearing action of the screw. Residual impurities are then removed through a filter screen, and finally, the melt is extruded through a die and granulated to form regular granular recycled material. This process not only facilitates the storage and transportation of recycled material but also improves its reprocessing performance.

Depending on the type of plastic and recycling requirements, pelletizers can be divided into single-screw and twin-screw types. Single-screw pelletizers have a relatively simple structure and are suitable for recycling heat-sensitive plastics such as PVC and PET. Twin-screw pelletizers, on the other hand, have stronger mixing and plasticizing capabilities and are suitable for recycling materials such as PP and PE. They also allow the addition of stabilizers, toughening agents, and other additives during the pelleting process to improve the performance of the recycled material.

Key control parameters in the pelleting process include melt temperature, screw speed, and die pressure. These parameters need to be precisely adjusted according to the melt index and thermal stability of different plastics to ensure consistent quality of the recycled pellets. High-quality recycled pellets should have uniform size, good flowability, stable melt strength, and low impurity content; these characteristics directly affect their subsequent processing performance and the quality of the final product.

III. Industry Applications of Rigid Plastic Recycling Machines

Rigid plastic recycling machines have wide applications in various industries, providing a resource-based solution for plastic waste in different fields. Understanding these applications helps us recognize the value and potential of rigid plastic recycling.

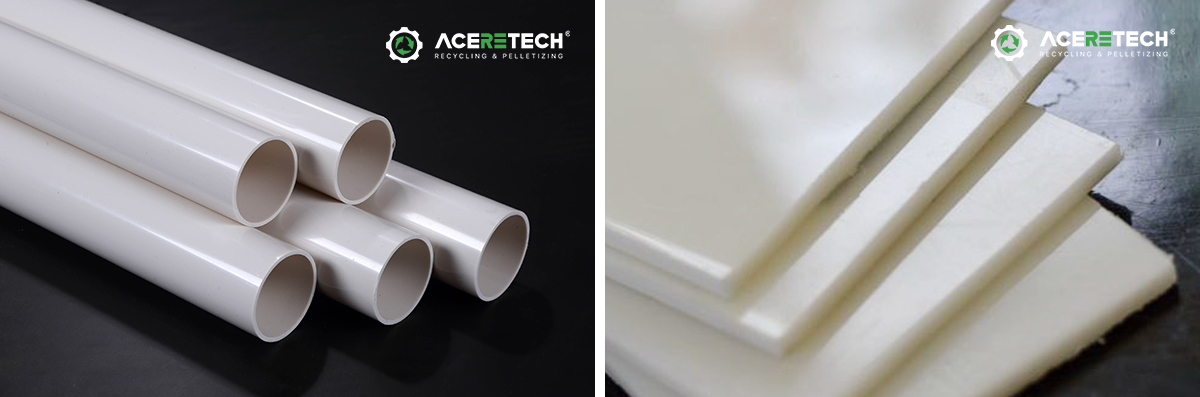

1. Recycling of Construction Waste

The construction industry is a major application area for rigid plastics and also one of the main sources of rigid plastic waste. PVC pipes, window frames, flooring, and other construction plastic products are often treated as construction waste after their service life. Rigid plastic recycling machines can convert these wastes into recycled pellets for the production of new construction plastic products, achieving material recycling. For example, recycled PVC pellets can be used to produce low-requirement products such as drainage pipes and wiring ducts; recycled PP pellets can be used to produce interior decoration materials.

Construction waste is typically large in volume, irregular in shape, and may contain impurities such as cement and sand, placing high demands on recycling equipment. Modern construction plastic recycling systems are usually equipped with heavy-duty shredders and multi-stage crushers, which can effectively process these special wastes and remove impurities through multi-stage washing to ensure the quality of recycled pellets.

2. Recycling of Packaging Waste

The packaging industry is another major application area for rigid plastics. Plastic containers, pallets, turnover boxes, and other packaging materials are often discarded after use. Rigid plastic recycling machines can convert packaging waste into recycled pellets for the production of new packaging materials or other plastic products. For example, recycled PET bottle flakes can be used to produce fibers and sheets; recycled HDPE pallet pellets can be used to produce injection molded products.

Packaging industry waste is generally clean, but comes in various shapes and may contain contaminants such as labels and printing inks. To address these characteristics, packaging plastic recycling systems are typically equipped with pre-sorting equipment to remove large impurities such as labels, and employ multi-stage washing processes to remove contaminants such as ink and adhesives, ensuring the purity of the recycled pellets.

3. Recycling of Automotive Industry Waste

The automotive industry uses a large amount of plastic materials, such as bumpers, dashboards, and interior parts. These plastic parts are often disposed of as waste at the end of their service life. Rigid plastic recycling machines can convert this automotive plastic waste into recycled pellets for the production of new automotive plastic parts, achieving material recycling. For example, recycled PP dashboard pellets can be used to produce automotive interior parts; recycled PVC bumper pellets can be used to produce cable sheaths.

Automotive plastic waste typically contains a mixture of metals, fiberglass, and other materials, and the diverse types of plastics impose specific requirements on recycling equipment. Modern automotive plastic recycling systems are usually equipped with sophisticated sorting equipment to remove impurities such as metals, and employ multi-stage crushing and washing processes to handle different types of plastics, ensuring the quality of recycled pellets.

IV. Future Technological Innovations in Rigid Plastic Recycling Machines

Future technological innovations in rigid plastic recycling machines will primarily focus on several aspects: first, increasing equipment processing capacity to achieve larger-scale recycling production; second, increasing automation to reduce manual intervention and lower labor costs; third, improving washing and pelletizing quality to expand the application range of recycled pellets; and fourth, developing specialized recycling technologies to increase the recycling rate of special plastics such as composite materials and multilayer co-extruded materials. These technological innovations will make rigid plastic recycling more efficient, economical, and environmentally friendly.