Article Paragraphs:

I. Core Functions of Plastic Pelletizers

II. Common Classifications of Plastic Pelletizers

III. ACERETECH Granulator Series and Applicable Materials

IV. Choosing the Right Granulator is Key to Success

Plastic pelletizers play a crucial role in the recycling and reuse of plastics. Pelletizers transform waste and crushed plastic materials into granular recycled plastic raw materials that are easy to store, transport, and reprocess through a series of precise processes including melting, plasticizing, filtering, shearing, and cooling. Understanding the functions, classifications, and applications of plastic pelletizers is essential for selecting the right equipment and achieving efficient recycling. As a leading manufacturer of plastic recycling machines, ACERETECH is pleased to provide you with an in-depth analysis.

I. Core Functions of Plastic Pelletizers

The core function of plastic pelletizers is to transform loose, irregularly shaped recycled plastics into uniform, regular granules. This process not only increases the added value of plastics but also facilitates downstream molding processes such as injection molding, blow molding, and extrusion. Its main functions include:

Melting and Plasticizing: Solid plastic particles or fragments are melted into a uniform melt through heating and the shearing action of the screw.

Degassing and Volatilization: For plastics containing moisture or volatile substances (such as PET), some advanced equipment has a degassing function to remove volatile substances from the melt, ensuring granule quality.

Filtration and Purification: The melt passes through a filter to remove impurities, dust, debris, etc., improving the purity of the recycled material.

Metering Extrusion: The extrusion rate of the melt is precisely controlled, and continuous strips are formed through a die of a specific shape.

Pelletizing: The strip-shaped melt is cut into granules of a specific size using a pelletizing blade.

Cooling and Shaping: The granules are rapidly cooled and solidified by water or air cooling for easy subsequent processing.

II. Common Classifications of Plastic Pelletizers

Plastic pelletizers can be classified in various ways, commonly based on screw structure, processing stage, and degree of automation. Classification by screw structure is the most common, mainly divided into single-screw pelletizers and twin-screw pelletizers. Single-screw pelletizers: Relatively simple in structure, low in maintenance costs, and well-suited for certain plastics (especially harder and purer ones). They can be further divided into single-stage and two-stage types depending on the processing flow.

Twin-screw pelletizers: Typically have a parallel or conical structure, offering stronger mixing and plasticizing capabilities, especially excelling in processing mixed plastics, requiring fine modification, or demanding high degassing efficiency.

III. ACERETECH Granulator Series and Applicable Materials

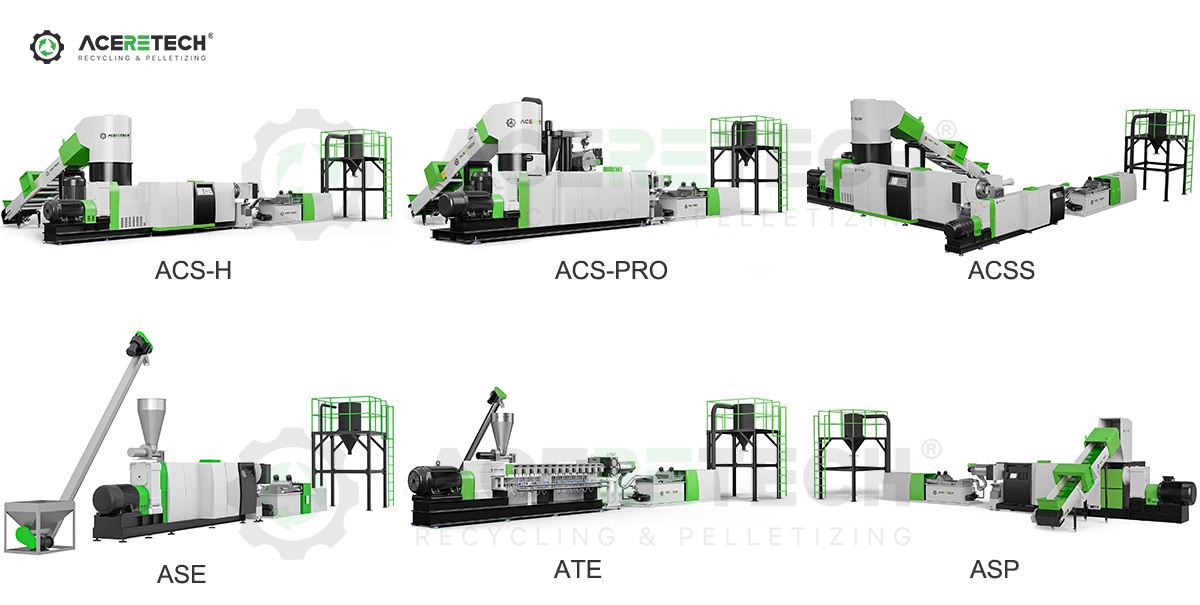

ACERETECH has meticulously crafted a variety of high-performance plastic pelletizers to meet the diverse needs of different recycling scenarios, covering a wide range of applications from basic recycling to fine modification. Below are some of our main products and their features and applicable materials:

Single-screw compaction granulator series

Single-screw design, compact structure, and relatively simple operation and maintenance.

Features: Integrates compaction, melting, extrusion, and pelletizing into one unit, offering high efficiency and a small footprint. Suitable for processing various common recycled plastics.

Applicable Materials: Widely applicable to various relatively pure recycled plastics such as HDPE (e.g., drums, bottles, films), PP (e.g., woven bags, crates), and PVC (rigid). Ideal for small to medium-sized recycling projects.

Features: Based on the ACS-H, the degassing and filtration systems have been significantly enhanced, effectively removing moisture, volatile substances, and fine impurities from the melt, significantly improving the purity and stability of the recycled pellets.

Applicable Materials: Particularly suitable for processing materials with high moisture content or high purity requirements, such as PET bottle flakes, heavily soiled HDPE/PP recycled materials, and applications requiring higher quality granules.

Two-stage design: The first stage typically handles initial crushing and compaction, while the second stage handles fine melting, plasticizing, and extrusion. This provides stronger processing capacity and better adaptability to mixed materials.

ACSS Two-Stage Single-Screw Plastic Compactor Granulator:

Features: Employs a two-stage process, with the first stage for compaction and crushing, and the second stage for fine melting and extrusion. This is more effective for processing thicker, harder materials or materials with certain impurities.

Applicable Materials: Suitable for thicker HDPE/PP sheets, rigid sheet plastics, and some industrial scraps. Effectively processes materials that are difficult to plasticize.

Features: Focused on granulation of rigid plastic sheets, with a highly targeted structural design to ensure effective melting and extrusion of the sheets.

Applicable Materials: Primarily used for processing rigid plastic sheets, such as thick sheets, plates, and sheet scraps of PP/HDPE.

Features: Also a two-stage design, focused on processing rigid plastic sheets, typically offering stronger shearing force and better melting effect.

Applicable Materials: Specifically designed for rigid plastic sheets, such as thick PP/HDPE sheets, sheet scraps, and certain engineering plastic sheets, efficiently converting them into qualified granules.

Features: Integrates shredding, single-screw extrusion, and pelletizing processes into a complete in-plant recycling line with a high degree of automation, suitable for direct processing of scraps on the production site.

Applicable Materials: Designed specifically for in-plant recycling, suitable for processing various plastic scraps and waste generated during production, such as PP, PE, and PVC.

Twin-Screw Granulators and Modified Recycling

More than just recycling, it's an upgrade! Twin-screw granulators give waste plastics a new lease on life through precise modification, resulting in superior performance and higher value.

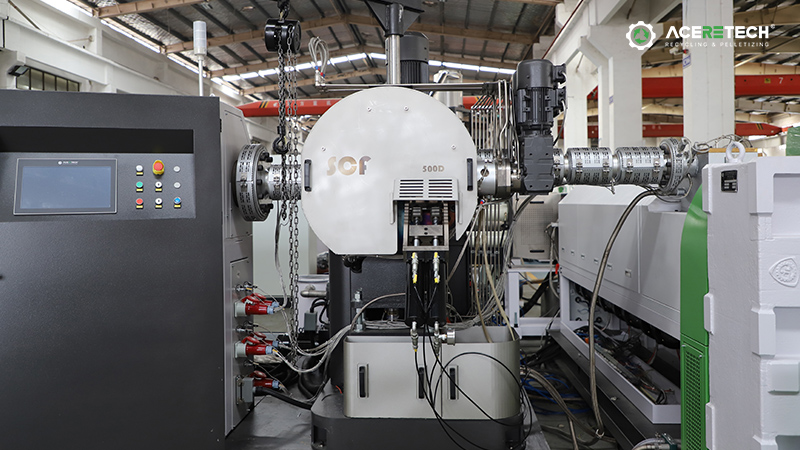

Features: Utilizes a parallel twin-screw structure, offering exceptional mixing, plasticizing, and degassing capabilities. It can handle more complex plastic mixtures and facilitates the addition of modifiers for plastic modification. It is typically equipped with an advanced degassing system.

Applicable Materials: Not only suitable for granulating various mixed plastics, but also capable of modifying and recycling plastics, such as adding fillers, reinforcing agents, and masterbatches to produce high-performance specialty materials.

IV. Choosing the Right Granulator is Key to Success

As you can see, different types of ACERETECH plastic granulators have different focuses. Choosing the right one requires comprehensive consideration of factors such as the specific type of recycled material, impurity content, desired pellet quality, throughput, and budget. We recommend that you thoroughly assess your needs and consult our technical experts for the most professional equipment recommendations.

ACERETECH is committed to providing efficient and reliable plastic recycling solutions. Whether you're looking for a single-screw extruder to process everyday waste or a twin-screw system for recycling and modifying complex mixtures, we can meet your needs.