Plastic Crusher

As the world transitions to a circular economy, PET bottle recycling has become a critical issue for both environmental protection and economic development. Efficient PET bottle recycling not only reduces plastic pollution but also creates sustainable economic value for businesses. To achieve efficient recycling, a high-performance PET bottle recycling production line is essential, and the performance of the crusher, the first step in the production line, directly determines the overall effectiveness of the recycling project. This article will provide a detailed introduction to the Aceretech GH series heavy-duty crushers (taking the GH700/1000 model as an example), analyzing how its innovative configuration and intelligent design make it an ideal choice for PET bottle recycling and crushing.

I. PET Bottle Recycling: Driven by Both Environmental and Economic Benefits

The necessity of PET bottle recycling is becoming increasingly evident, and its environmental and economic value cannot be ignored. Let's explore the key significance of PET bottle recycling from the perspective of both environmental and economic drivers.

1. Environmental Benefits: Curbing Pollution and Contributing to Carbon Neutrality Goals

Reducing plastic pollution:

Discarded PET bottles are one of the main sources of global plastic pollution. PET bottles have a long degradation cycle, lasting hundreds of years, posing a long-term threat to soil, river, and marine ecosystems. Therefore, efficient PET bottle recycling is an important means of addressing the plastic pollution problem.

Contributing to global carbon neutrality:

The carbon emissions of recycled PET (rPET) are significantly lower than those of virgin PET. Recycling 1 ton of PET bottles is equivalent to reducing approximately 1.5 tons of carbon dioxide emissions, helping businesses and society achieve carbon neutrality goals.

Alleviating landfill pressure:

PET bottle recycling can significantly reduce the amount of waste in landfills, effectively alleviating the pressure on urban land resources.

2. Economic Benefits: High-Value Resources, Contributing to Sustainable Development

Achieving a closed-loop resource cycle:

PET bottles are considered a valuable resource in the "urban mine." Through recycling, PET bottles can be transformed into high-value rPET flakes, which can be used to produce food-grade packaging, textiles, industrial sheets, etc., forming a "bottle-to-bottle" or "bottle-to-fiber" closed-loop industrial chain.

Stable market returns:

With the increasing global demand for sustainable materials, the rPET market has broad prospects. Investing in PET bottle recycling can not only create considerable economic returns but also enhance a company's brand image and social responsibility.

II. Core Equipment: Detailed Explanation of the Aceretech GH700/1000 Heavy-Duty Shredder

In the entire PET bottle recycling process, shredding is a crucial step. Choosing an efficient and intelligent shredder can significantly improve recycling efficiency and output quality. The Aceretech GH series heavy-duty shredder is designed to meet high-volume, high-intensity shredding demands.

Case Model: GH700/1000

The Aceretech GH series shredder features a robust, all-steel welded structure, specifically designed to handle various hard, large plastic waste materials (including PET bottles). Its modular and high-performance design ensures long-term stable operation under high-intensity working conditions.

Technical Highlights and Configuration Advantages

Intelligent Feeding System: Material Conveyor Belt + Hydraulic Pusher

Configuration Analysis:

The GH700/1000 is equipped with a material conveyor belt and an innovative hydraulic pusher system, ensuring uniform feeding and continuous supply of PET bottles through intelligent control.

Advantages:

Optimized Energy Efficiency: The intelligent feeding system avoids idling and overloading, reducing energy waste and improving overall production efficiency.

Maximized Processing Capacity: The hydraulic pusher can forcibly press larger PET bottles into the shredding chamber, greatly increasing shredding capacity.

Powerful Shredding Core: 700mm Rotor Diameter, 1000mm Rotor Width

Technical Analysis:

The GH700/1000 is equipped with a 700mm diameter rotor and a 1000mm ultra-wide rotor, capable of easily shredding whole PET bottles, even complex materials with labels and caps.

Advantages:

Uniform Shredding: The V-shaped blades and "X-shaped" shearing design of the rotor ensure uniform shredded material size, improving the efficiency of subsequent processing.

High Production Capacity: The ultra-wide rotor provides physical assurance for high production volume, ensuring stable and efficient operation of the production line.

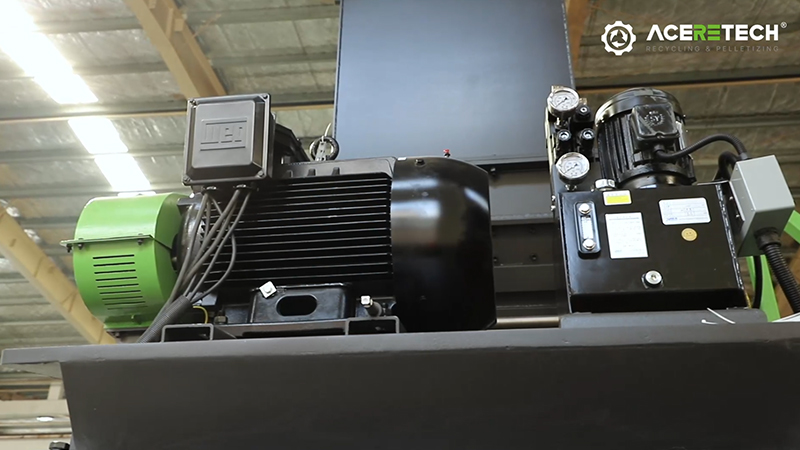

Power Guarantee: WEG and other international brand motors

Configuration Analysis:

The GH series uses high-quality motors (such as WEG motors), guaranteeing the shredder's powerful output and long-term stable operation.

Advantages:

Energy Saving and Low Noise: International brand motors provide high energy efficiency and low noise operation, reducing long-term operating costs and equipment maintenance frequency for businesses.

Intelligent Operation: Frequency Conversion Control and System Linkage

Technical Analysis:

The GH700/1000 adopts a frequency conversion control system and is equipped with intelligent linkage logic, which monitors the current load in real time and automatically adjusts the feeding speed, ensuring the equipment always operates efficiently.

Advantages:

Adaptive Adjustment: Automatically optimizes the production process, avoiding idling and overloading, and improving work efficiency.

Simplified Operation: Reduces manual intervention, lowering operating difficulty and personnel training costs.

III. Conclusion: Choosing Aceretech GH Series for Efficient and Intelligent PET Bottle Recycling

PET bottle recycling is a crucial link in promoting green development and achieving economic benefits, and choosing an efficient and intelligent shredder is key to achieving this goal. The Aceretech GH700/1000 heavy-duty plastic shredder, with its intelligent feeding system, powerful shredding core, international brand motor, and intelligent operating system, solves the three major problems of efficiency, stability, and finished product quality in the recycling process. It provides higher production capacity, more stable performance, and higher quality product output for PET bottle recycling projects, making it an ideal choice in the field of PET bottle recycling.