Introduction

In the field of plastic recycling, the recycling and pelletizing of PET flakes is a relatively mature process. However, when other polymers such as PE (polyethylene) are mixed in, traditional processes often face significant challenges. The low melting point of PE and its incompatibility with PET easily lead to material clumping and uneven plasticization during the melting process, severely affecting production efficiency and the quality of recycled pellets. So, how can we achieve stable and efficient recycling of PET flakes containing approximately 10% PE impurities? This article will use Aceretech's ACS-H series plastic recycling machine as an example to reveal a mature solution, delving into the core advantages of the crystallization stirring system, single-screw extrusion, and strand pelletizing technology in the processing of mixed materials.

I. Challenge Analysis: Material Characteristics and Recycling Difficulties of PET Flakes Containing PE

To solve the problem, we must first understand its root cause. The main difficulties in recycling PET flakes containing 10% PE are:

Large difference in melting points: The melting point of PET is approximately 250°C, while the melting point of PE is only 120-135°C. During traditional heating processes, the PE will melt prematurely and surround the incompletely softened PET flakes, forming sticky clumps that hinder heat transfer.

Incompatibility: PET and PE are two thermodynamically incompatible polymers. If the mixing is uneven, it will lead to quality problems such as delamination and decreased mechanical properties in the recycled pellets.

Poor processing stability: Material clumping can lead to uneven feeding of the extruder, large pressure fluctuations, unstable motor load, and even equipment shutdown.

Therefore, a plastic pelletizing machine capable of effectively processing this mixed material must possess unique pretreatment and mixing and plasticizing capabilities.

Addressing the above challenges, Aceretech's ACS-H production line builds an efficient and stable PET flake recycling and pelletizing system through the following four key technological aspects.

1. Efficient Pre-treatment: Belt Conveying and Crystallization Mixing System

Belt feeding system: Ensures continuous and stable material conveying, laying the foundation for subsequent processes. The heart of the entire solution lies in the crystallization mixing system.

This system doesn't simply heat the material; instead, in a sealed, agitated container, through friction and external heating, it brings the PET flakes to a temperature close to crystallization (approximately 150-180°C) before entering the extruder. This process has two core functions:

Preventing PE clumping: At this temperature, although the PE has softened, continuous stirring evenly disperses it, preventing it from clumping together in large areas.

Improving plasticization efficiency: PET flakes that have undergone pre-crystallization and pre-heating have a more stable internal structure and can melt faster and more evenly after entering the extruder, significantly reducing the energy consumption and load of the extruder.

2. Power Core: High-Quality Single-Screw Extruder

The pre-treated material enters the single-screw extruder. The single screw used in the ACS-H series is specially designed, with a screw configuration optimized for processing mixed materials, providing strong shearing force and conveying capacity, ensuring further uniform mixing of PE and PET in the molten state.

The key lies in the power source: the entire machine is equipped with motors and gearboxes from leading international brands such as Siemens. This not only ensures long-term, high-load stable operation of the equipment, but also means excellent energy efficiency and reliability, making it the "heart" of the efficient operation of the entire production line.

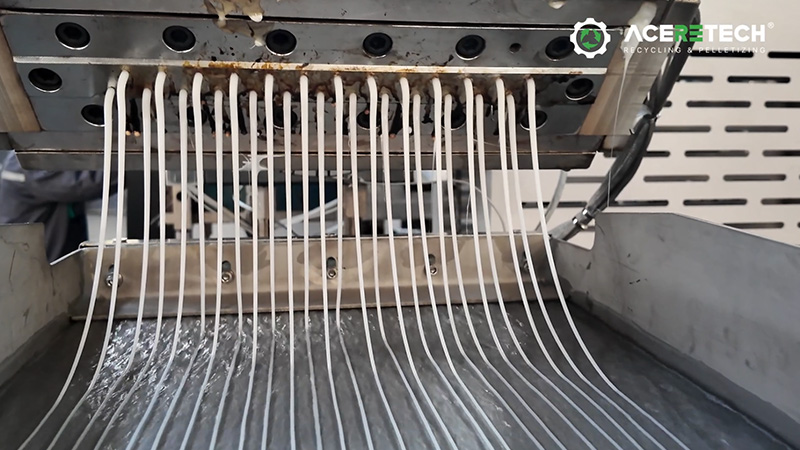

3. Precise Molding: Stable Strand Pelletizing Method

When the molten, uniformly mixed plastic melt is extruded from the die head, we use the classic strand pelletizing method. The advantages of this method are:

Controllable process: Operators can visually observe the color, bubbles, and plasticization of the strands, and adjust process parameters in a timely manner.

High pellet quality: The strands are pelletized after sufficient cooling. The finished pellets are regular in shape, uniform in size, free from agglomeration, and have a very low moisture content, allowing for direct use without complex drying treatment.

Wide Applicability: For materials like PET, which have high requirements for moisture content and appearance, strand pelletizing is the ideal choice to ensure final product quality.

III. Conclusion: Choosing a Professional Plastic Recycling Machine for Maximum Value

Processing PET flakes containing PE is no longer a technical challenge. The key lies in choosing a plastic recycling machine that provides a systematic solution based on the material characteristics.

Aceretech's ACS-H production line, through its ingenious pre-treatment with a crystallization and mixing system, a powerful single-screw extruder driven by a branded motor, and a stable strand pelletizing process, perfectly overcomes the recycling barriers of mixed materials. It not only solves the problems of clumping and instability during production but also produces high-quality recycled pellets, truly enabling customers to achieve value enhancement by "turning waste into treasure."

Click the link below to view the factory acceptance test video. If you are facing similar challenges in recycling mixed materials and need to invest in a technologically mature and well-configured plastic granulating machine, contact us to customize a complete recycling solution for you.