Against the backdrop of the accelerating global energy transition towards clean and low-carbon sources, lithium-ion batteries, as core energy storage units, are widely used in new energy vehicles, energy storage power stations, consumer electronics, and other fields.

With the rapid increase in the number of lithium-ion batteries in use, the recycling and disposal of waste lithium-ion batteries has become an unavoidable and important issue in the new energy industry chain.

In the lithium-ion battery recycling process, the lithium-ion battery separator, as a key non-metallic component, requires efficient crushing and recycling treatment, which directly impacts recycling safety, resource utilization rate, and overall economic benefits.

This article will systematically analyze the necessity of lithium-ion battery separator recycling and focus on introducing the Aceretech GE series lithium-ion battery separator crusher, explaining its core advantages and application value in the field of separator recycling.

I. What is a Lithium-ion Battery Separator? Why Must It Be Recycled?

Lithium-ion battery separators are usually made of polyethylene (PE) or polypropylene (PP). They are microporous polymer films located between the positive and negative electrodes. Their main functions include:

Preventing direct contact between the positive and negative electrodes to avoid short circuits

Allowing lithium ions to pass freely

Improving battery safety and cycle life

Although the separator accounts for a small proportion in a single battery cell, its total amount is enormous in large-scale retired lithium-ion batteries, and its recycling value and environmental impact cannot be ignored.

II. Analysis of the Necessity of Lithium-ion Battery Separator Recycling

1. Environmental Protection and Safety: Unavoidable Risk Control

Preventing potential pollution spread

Waste lithium-ion batteries contain residual electrolyte and heavy metals, which, if not properly handled, may cause long-term pollution to soil and water sources. If the separator is mixed with other components, it will increase the difficulty of dismantling and subsequent sorting.

Reducing plastic pollution

The separator is essentially a high-performance plastic film that is difficult to degrade naturally. Through professional recycling and crushing treatment, the environmental pressure caused by landfill and incineration can be effectively reduced.

2. Resource Recycling and Enhanced Economic Value

Achieving PE/PP plastic resource regeneration

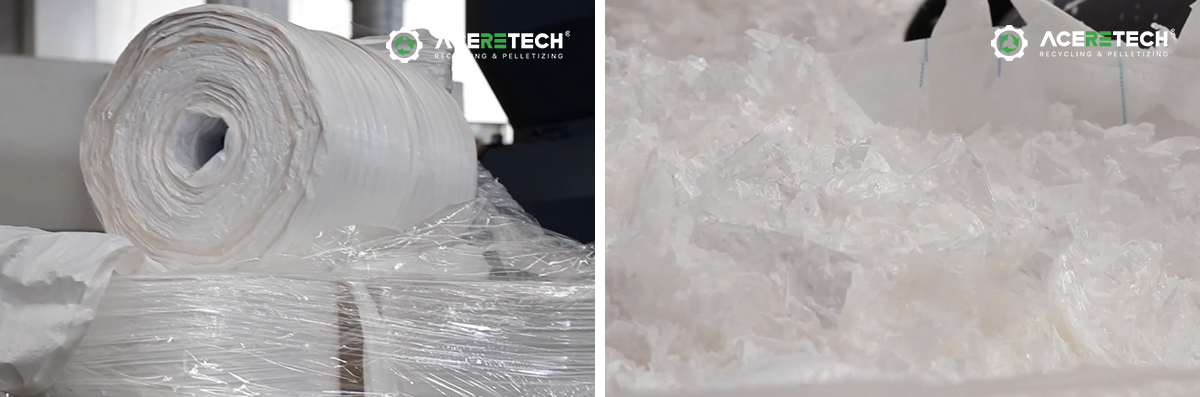

After crushing, cleaning, and granulation, the separator can be made into recycled plastic granules for the production of plastic products such as pallets, pipes, and building templates.

Improving overall profitability of lithium-ion battery recycling

In the "disassembly-crushing-separation-purification" process, efficiently separating non-metallic materials such as separator membranes in advance helps to improve the purity and efficiency of lithium, cobalt, and nickel recovery.

III. Challenges and Equipment Requirements for Lithium-ion Battery Separator Membrane Crushing

Lithium-ion battery separator membranes have the following typical characteristics:

* Lightweight and thin texture

* High toughness, easily wraps around the cutter shaft

* Prone to static electricity and fluffy accumulation during the crushing process

Common problems encountered when processing separator membranes with traditional plastic crushers include:

* Severe shaft entanglement

* Screen clogging

* Uneven output particle size

* Unstable equipment operation

Therefore, a lithium-ion battery separator membrane crusher specifically designed for thin film materials has become a core piece of equipment in the recycling line.

IV. Aceretech GE Series Lithium-Ion Battery Separator Membrane Crusher Solution

Core Equipment: GE Series Economical Plastic Crusher

The Aceretech GE series is a cost-effective crushing equipment specifically designed for films, sheets, and flexible plastic waste, and performs particularly well in the field of lithium-ion battery separator membrane recycling.

1. V-shaped Rotor + X-shaped Shearing Structure for Effective Anti-Tangle Performance

Technical Features:

V-shaped mounting angle for the rotating blades

Forms an X-shaped shearing path with the stationary blades

Dual-shear high-efficiency cutting structure

Application Advantages:

Precise shearing of separator film, preventing stretching and tangling

Stable and continuous crushing process

Uniform output size, facilitating subsequent cleaning and sorting

2. Multiple Rotor Width Configurations to Suit Different Recycling Scales

Available Models:

Rotor width: 500mm – 1400mm

Common models: GE500/500, GE500/700, GE500/1000, etc.

Advantages:

Suitable for small to medium-scale pilot lines to industrial-scale recycling lines

Fully meets the material handling requirements of fluffy separator film

Flexible matching of investment cost and production capacity

3. Intelligent Variable Frequency Feeding System Ensures Continuous and Stable Operation

Belt conveyor + ABB/Schneider frequency converter

Real-time monitoring of main motor load

Automatic adjustment of feeding speed

Core Value:

Prevents instantaneous overload and material blockage

Reduces manual intervention

Enhances overall line automation and safety

4. Industrial-Grade Structural Design, Suitable for Long-Term High-Intensity Recycling Operations

40mm high-strength steel plate crushing chamber

DC53 high wear-resistant blades (62–64 HRc)

Anti-vibration and noise reduction structural design

Convenient and quick maintenance, blade and screen replacement

5. Why Choose Aceretech GE Series Lithium Battery Separator Film Shredder?

Summary of Core Advantages:

Optimized for thin film materials, solving the entanglement problem

Suitable for lithium battery separator film recycling processes

Stable operation, low maintenance costs

Improves the overall efficiency and economics of lithium battery recycling

The Aceretech GE series lithium battery separator film shredder has become an ideal choice for safe, efficient, and economical recycling in the new energy recycling industry.

FAQ

Q1. What are the typical process flows for lithium battery separator film recycling?

A: A typical lithium battery separator film recycling process includes:

Battery disassembly or crushing pretreatment, initial separation of separator film and electrodes, separator film crushing, cleaning, dewatering, drying, and regeneration granulation or classification and utilization.

Q2. Will the lithium battery separator film shredder wear out quickly? Are the maintenance costs high?

A: No. The GE series features DC53 high-wear-resistant blades (62–64 HRc) and a high-strength steel plate crushing chamber.

Compared to ordinary blades: it has a longer service life; requires less frequent blade changes; is easier to maintain; and has overall lower maintenance costs in the industry.

Q3. Can the lithium-ion battery separator film be recycled after crushing?

A: Yes.

The crushed separator film is processed through shredding, crushing, cleaning, drying, and granulation to produce recycled PE/PP plastic granules, which are used in: plastic pallets/pipes/construction formwork/industrial plastic products, achieving resource recycling.

Q4. How to choose a suitable lithium-ion battery separator film shredder manufacturer?

A: When choosing a manufacturer, it is recommended to focus on:

Whether they have experience in processing film materials;

Whether they have case studies in the lithium-ion battery recycling industry;

Whether the blade type and rotor structure are optimized for separator films;

After-sales and technical support capabilities;

Aceretech has mature equipment and engineering experience in the field of lithium-ion battery recycling and plastic regeneration.

Q5. Can the lithium-ion battery separator film shredder handle other materials?

A: Yes.

The GE series is not only suitable for lithium-ion battery separator films, but can also process: PE/PP films; plastic sheets; packaging films; small hollow plastic products; and has good versatility.