Abstract: In the field of plastic recycling, processing machine head materials presents a significant challenge due to their high hardness, large size, and irregular shape. This article will delve into why the two-step process of "LS single-shaft shredder + GE single-shaft crusher" is a more efficient, economical, and safer solution for processing machine head materials compared to traditional single crushing methods. We will use Aceretech's practical case to reveal how this golden rule brings significant benefits to recycling companies.

I. Plastic Lumps Recycling: A Challenge That Cannot Be Ignored

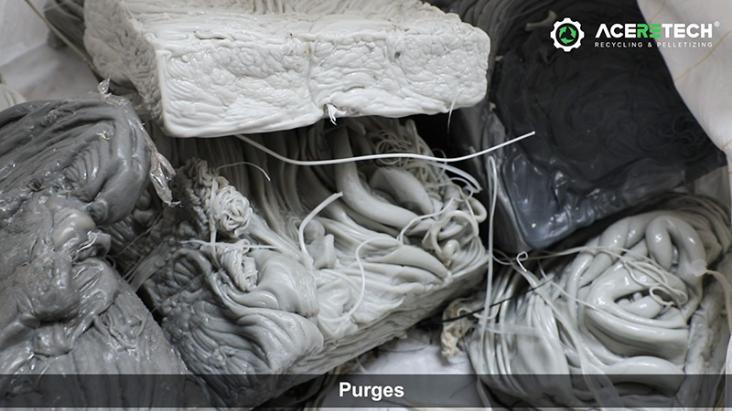

Plastic lumps, as the initial and final waste generated during injection molding or extrusion production, are common raw materials in plastic recycling. However, their characteristics also make them a challenge in the recycling process:

High Hardness and Large Volume: Plastic lumps are usually dense solid blocks, large in volume and high in hardness. Directly feeding them into a crusher will cause a huge impact on the equipment.

Irregular Shape: The materials are of varying shapes, making stable feeding difficult. They are prone to jamming in the crushing chamber, leading to equipment downtime and even damage to the blades.

High processing risk: Traditional crushers consume a lot of energy, generate significant noise, and experience severe blade wear when processing such materials, posing extremely high safety risks.

Faced with these challenges, simple and crude crushing is outdated. A scientific and efficient pretreatment process is crucial to ensuring the success of recycling projects.

II. "Tear Before Crushing": The Core Advantage of the Two-Step Method

For the characteristics of the plastic lumps, leading companies in the industry generally adopt a two-step process of "tear first, then crush." This is not simply a matter of adding equipment, but a well-thought-out system engineering approach centered on "cost reduction and efficiency improvement." We use Aceretech's LS series single-shaft shredder and GE series single-shaft crusher as examples. Taking the combination as an example, let's analyze its necessity.

The LS single-shaft shredder plays a pioneering role in the process, its core task being the preliminary processing of large, hard plastic lumps.

Core Functions: Pre-crushing and Volume Reduction

Low Speed, High Torque: The LS series shredder adopts a low-speed, high-torque design, which can "steadily, accurately, and forcefully" grasp large plastic lumps, breaking them down into smaller, more manageable fragments (typically 50-150mm) through shearing and tearing forces. This "slow but powerful" working method effectively avoids equipment damage caused by high-speed impacts.

Reducing Subsequent Load: After being processed by the LS shredder, the volume and hardness of the material are significantly reduced. This creates extremely favorable conditions for subsequent fine crushing, fundamentally solving the problems of feeding difficulties and high impact.

After the material exits the LS shredder, it enters the “home field” of the GE single-shaft crusher. In the video, the GE500-500 model (rotor diameter 500mm, width 500mm), customized according to customer needs, perfectly illustrates the value of fine crushing.

Core Functions: Homogenization and Granulation

High-Efficiency Fine Crushing: The GE series crushers are specifically designed to process pre-crushed plastic fragments into uniform, small-sized particles. Its high-speed rotating rotor, combined with fixed blades, can efficiently further crush the shredded material into ideal sizes (e.g., 10-20mm), meeting the requirements for subsequent granulation or direct utilization.

Optimized Performance and Lifespan: Since the material entering the GE crusher has already undergone pre-treatment, the equipment no longer needs to withstand huge impact loads. This directly brings three major benefits:

Significantly Reduced Energy Consumption: The crusher operates under optimal conditions, with stable current and lower energy consumption per unit output.

Extended blade life: Direct collisions with large, hard objects are avoided, significantly reducing blade wear and decreasing replacement frequency and maintenance costs.

Improved operational stability: Smooth feeding ensures continuous production and effectively prevents unexpected downtime due to material jams.

III. Differentiated Value: Why is Aceretech's "LS+GE" Combination the Superior Solution?

While the market is flooded with shredder and crusher brands, Aceretech's "LS+GE" combination solution stands out due to its profound customer insights and sophisticated design philosophy.

From "Confrontation" to "Collaboration": We don't view the recycling process as a "confrontation" between equipment and materials, but rather as a collaborative process between the equipment. The LS shredder tackles the challenging material, while the GE crusher minimizes particle size.

Customization Capabilities, Tailored to Real Needs: Aceretech offers highly customized rotor diameter and width configurations based on the customer's specific material characteristics, output requirements, and final particle size. This "customization" ensures precise investment and a high return on investment.

Focus on Total Life Cycle Cost (TCO): Our solutions not only focus on equipment purchase costs but also on the customer's long-term operating costs. Through the "shredding before crushing" process, customers reduce energy consumption, tool maintenance, manual intervention, and equipment depreciation. Long-term expenditures in areas such as [specific areas] will be effectively controlled. While the initial investment may be slightly higher than a single large crusher, the resulting stability and low TCO will create a more sustainable competitive advantage for the company.

Conclusion: Invest in the process, not just the equipment.

When processing headstock materials, choosing the right process path is far more important than choosing a single, "powerful" piece of equipment. Aceretech's two-step approach of "LS single-shaft shredder + GE single-shaft crusher" is precisely such a proven, scientifically efficient recycling process.

It is not merely a combination of two pieces of equipment, but a wise decision to invest in production efficiency, operational safety, and long-term profitability. For any company seeking to establish a core advantage in the plastics recycling sector, understanding and adopting this "golden rule" will be a crucial step towards success.

Click the link below to view the video of the plastic lumps shredding and crushing operation: