1. PET waste: a valuable resource that needs to be recycled

Polyethylene terephthalate (PET) is an important engineering plastic, widely used in beverage bottles, food packaging, fibers and other fields. However, if a large amount of PET waste is not properly handled after use, it will cause serious pollution to the environment. At the same time, PET is also a valuable resource that can be recycled. Through pelletizing processing, it can be converted into recycled PET raw materials for the production of new PET products to achieve resource recycling.

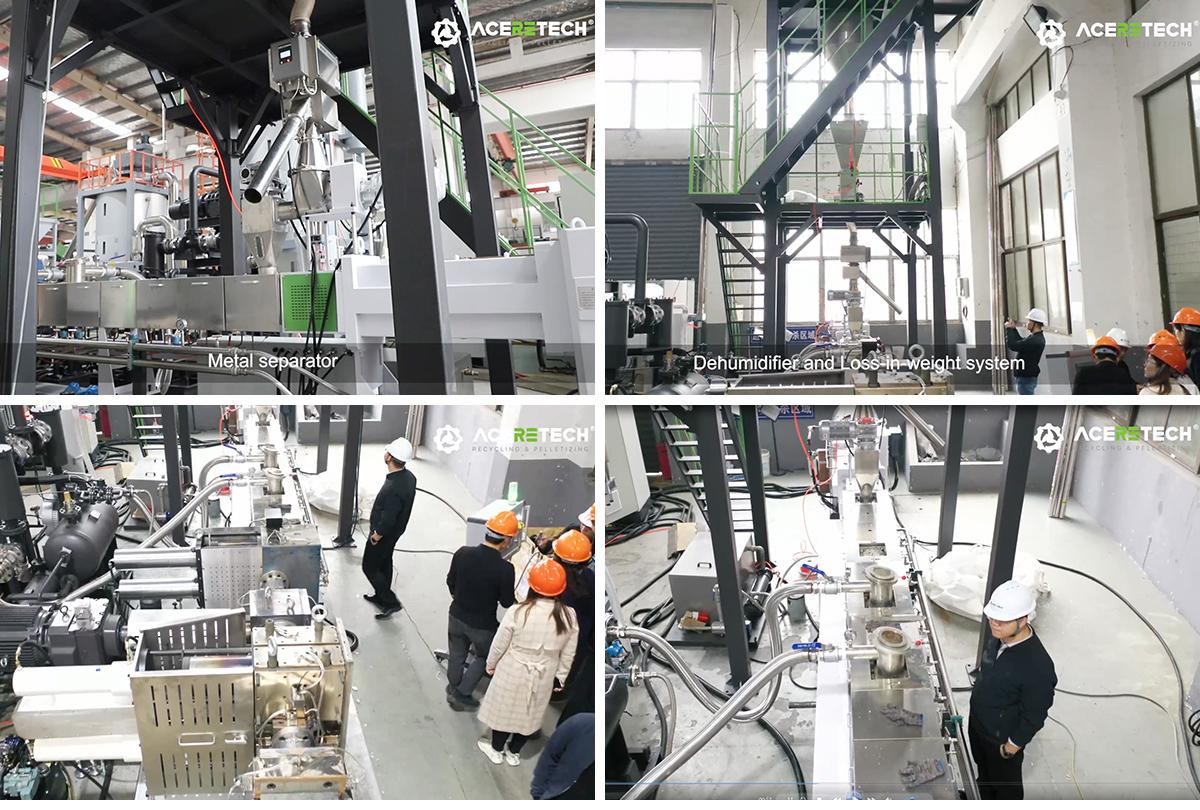

As a leading company in the field of plastic recycling and pelletizing, ACERETECH recommends the use of ATE parallel twin-screw pelletizer for recycling and pelletizing based on the characteristics of PET waste. The equipment uses advanced technology and precision components to ensure efficient recycling and high-quality regeneration of PET waste.

Main configuration and functions:

☆ Screw loader and buffer silo: realize automatic feeding and buffer storage of PET waste to ensure the continuity of the production process.

☆ Screw loader and Crystallizer: transport PET waste to the crystallizer for crystallization, improve the crystallinity of PET and improve its processing performance.

☆ Dryer: remove moisture from PET waste, prevent hydrolysis and degradation, and improve product quality.

☆ Dehumidifier and Loss-in-weight system: further remove moisture from PET waste and achieve accurate metering to ensure stable product quality.

☆ Branded gearbox: strong power, smooth operation, low noise and long service life.

☆ Parallel twin-screw extrusion, screw length-to-diameter ratio: 95/40: parallel twin-screw design, large length-to-diameter ratio, strong shear force, uniform plasticization, ensure full melting and uniform mixing of PET waste.

☆ Metal separator: effectively remove metal impurities in PET waste, protect subsequent equipment and improve product purity.

☆ Root pump unit: Provides stable vacuum, effectively removes moisture and volatiles from PET melt, and improves the purity and stability of particles.

☆ None-Stop Piston Type Filter: The filter can be replaced without stopping the machine to ensure continuous production and improve production efficiency.

☆ Lamp tube: Observe the melting and plasticization of materials, so as to adjust the process parameters in time.

☆ Intelligent control system: Realizes automatic control of equipment, improves production efficiency and stability.

☆ Back flush filter: Back flushes the filter system to extend the service life of the filter and reduce production costs.

☆ Water-cooled strand pelletizing: The water-cooled strand pelletizing method is adopted, and the particles are uniform and not easy to stick together, which improves product quality.

☆ Vibration dryer: Effectively removes moisture from the surface of particles and improves drying efficiency.

☆ Lifting dryer hopper: Convenient for conveying and storing dried particles.

☆ Weighing silo: Accurate measurement, convenient for subsequent packaging and transportation.

3. Advantages of ACERETECH ATE Parallel Twin Screw Pelletizer

☆ Efficient recycling: Optimized design for PET waste characteristics to achieve efficient recycling and high output.

☆ High-quality regeneration: Advanced crystallization, drying, filtration and degassing systems to ensure the purity and high quality of the particles.

☆ Intelligent control: Intelligent control system to achieve automated control of the production process.

☆ Stable and reliable: Using high-quality materials and precision components, the equipment operates stably and reliably with a long service life.

4. Conclusion

ACERETECH ATE parallel twin screw pelletizer provides customers with an efficient, professional and intelligent PET waste recycling pelletizing solution, helping to recycle resources and promote the sustainable development of the plastics industry.