In today's era of increasing attention to environmental protection and resource recycling, waste cloth recycling shredders have opened up an efficient and environmentally friendly channel for the treatment and reuse of waste cloth.

Main material classification of waste cloth

The main material classification of waste cloth is varied, and the common ones are cotton, chemical fiber and blended. Cotton waste cloth is soft and skin-friendly, with good moisture absorption, and is commonly found in the scraps of clothing, sheets and other products; chemical fiber waste cloth has the characteristics of high strength, wear resistance, and not easy to deform, and mostly comes from various synthetic fiber products; blended waste cloth is a mixture of cotton, chemical fiber and other materials, and has the characteristics of different materials. These waste cloths of different materials and forms, such as scraps, ready-made clothes, rolls, etc., have different thicknesses and hardness, which brings certain challenges to recycling and processing.

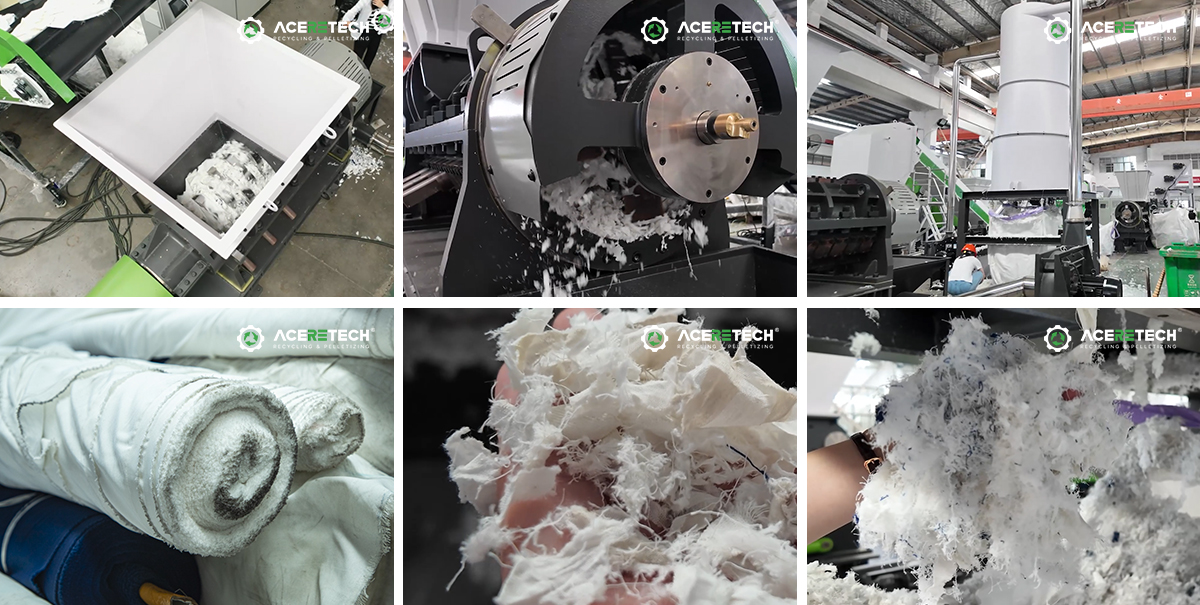

The DTS waste cloth shredder produced by ACERETECH has undergone rigorous factory testing before delivery to ensure its stable and reliable performance. The equipment is equipped with a belt conveyor, a DTS shredder and a pneumatic silo, forming a complete waste cloth processing system.

Processing capacity requirements

In terms of processing capacity, the DTS waste cloth shredder performs well. It can efficiently shred waste cloth of different materials and forms, whether it is soft cotton cloth, tough chemical fiber cloth, or blended cloth, it can easily handle it. For waste cloth with large differences in thickness and hardness, it can also be handled with ease. In terms of capacity matching, users can choose the appropriate power (usually 15-200kW) and throughput (hundreds of kilograms to several tons per hour) according to the amount of waste cloth generated, avoid overload or idling, and ensure efficient operation of the equipment.

Equipment performance requirements

Tool strength: The DTS waste cloth shredder uses tools made of high-alloy steel or wear-resistant materials (such as D2, SKD11), which can handle waste cloth mixed with metal impurities (such as zippers, buttons), ensuring that the equipment can still operate stably under complex working conditions.

Adjustable particle size: By adjusting the knife gap or screen, the discharge size (usually 20-100mm) can be controlled to meet the needs of subsequent recycling (such as recycled fiber, filler) or incineration. This flexibility enables the equipment to adapt to the diverse needs of different customers.

Low energy consumption design: The equipment optimizes the transmission system and adopts energy-saving technologies such as variable frequency motors to reduce energy consumption, reduce long-term operating costs, and save expenses for enterprises.

Shredder shaft: The DTS shredder shaft is forged from alloy structural steel and precision-machined by CNC to meet high-precision manufacturing requirements. The shaft and the cutter disc are connected by national standard splines, with high torque performance, making it easy to control in high-speed cutting.

Discharge port: The adjustable screen mechanism can flexibly control the discharge particle size to meet customer needs. The scraper is forged and precision-machined from hot-working die steel, which effectively resists wear on the steel surface and reduces material loss during continuous friction with the material.

Safety and reliability

Protective measures: The equipment complies with mechanical safety standards (such as CE, OSHA), and is equipped with emergency brakes, overload protection and anti-rebound devices to provide all-round safety protection for operators.

Anti-entanglement design: According to the characteristics of the fiber, the equipment is designed with an anti-entanglement rotor or automatic cleaning mechanism to effectively reduce the number of shutdowns for maintenance and improve work efficiency.

Stability: The heavy-duty frame and shock-absorbing design ensure low vibration and low noise (<85dB) when the equipment is running at high speed, creating good conditions for the working environment.

Customer evaluation: Real feedback witnesses excellent quality

In actual applications, the DTS waste cloth shredder produced by ACERETECH has been highly praised by customers. Many customers said that the effect of the equipment in actual applications is obvious. For example, some customers mentioned that the shredder can quickly tear waste cloth, clothing, etc. into small pieces or fibers, reducing the volume of textile waste and facilitating subsequent storage and transportation. The shredded cloth fragments or fiber bundles can be used as the main raw material for recycled fibers, which are widely used in textile, clothing and other industries. At the same time, they can also be used as raw materials for papermaking, insulation materials and other industries, broadening the recycling channels of resources.

In terms of stability, customers reported that the shredder showed good stability and continuity during operation, and was able to work stably for a long time, reducing downtime. Low noise is also a point praised by customers. The shredder with low speed and high torque design produces low noise during operation and has less impact on the working environment. In addition, low energy consumption is also a major advantage. Compared with other types of crushing equipment, the shredder has low energy consumption, which helps to reduce the company's operating costs. Users can also adjust the shredder's output size according to actual needs to adapt to different subsequent processing processes.

Of course, customers also raised some precautions, such as blade wear. Since the cloth may contain impurities or parts with higher hardness, the blade may wear after long-term use. Therefore, users need to check the wear of the blade regularly and replace the severely worn blade in time. But overall, customers are very satisfied with the ACERETECH DTS waste cloth shredder and believe that it is an ideal choice in the field of waste cloth recycling and processing.