As an indispensable and convenient tool in modern life, the widespread use of plastic bags also brings severe environmental challenges. According to statistics, more than 100 billion plastic bags are produced worldwide each year, most of which are discarded within a few hours, becoming the main source of environmental pollution. It takes decades or even longer for these plastic bags to decompose in the natural environment, during which time they will cause long-term damage to soil, water sources and biodiversity. In the face of this global problem, the recycling of used plastic bags is particularly important. This article will introduce in detail the material types, usage status, and recycling process of plastic bags, especially the complete processing process from shredding, crushing, granulation to final extrusion products, as well as the various products that can be made from these recycled materials, to present readers with a complete plastic bag recycling system.

Material types and usage status of plastic bags

Plastic bags have their own unique physical and chemical properties and applicable scenarios depending on their materials. Understanding these differences will help us better carry out classified recycling work. At present, the common plastic bag materials on the market mainly include the following categories:

Polyethylene (PE): This is the most common plastic bag material, which can be divided into high-density polyethylene (HDPE) and low-density polyethylene (LDPE). HDPE plastic bags have a hard texture, low transparency but good heat resistance, and are often used for heavy-duty shopping bags; while LDPE plastic bags have high transparency and softness, and are widely used in disposable shopping bags and garbage bags. PE material meets the food packaging hygiene standards due to its non-toxic, odorless, moisture-proof, anti-oxidation, acid and alkali resistance, and is an ideal choice for food contact bags.

Polypropylene (PP): It has a hard texture, high transparency, good toughness, and is easy to construct. It is often used for food packaging such as packaging, fruit and vegetable bags, and bread wraps. Because PP material has good heat resistance, it is also often used in packaging scenarios that require a certain temperature tolerance.

Polyvinyl chloride (PVC): It is the second largest plastic variety after polyethylene. It is often used to make PVC bags, composite bags, vacuum bags, and packaging decorations for covers of books, folders, tickets, etc. However, PVC material is controversial in terms of environmental protection, especially its application in food contact materials is strictly restricted.

Polystyrene (PS): commonly used to make foam plastic bags, disposable tableware, etc., but this type of plastic is brittle and has a relatively low recycling value.

Polyvinyl alcohol (PVA): a biodegradable material that can be dissolved in water, easily melted and recycled, and is commonly used in compression bags, plastic wrap, etc.

The global consumption of plastic bags is huge every year, of which supermarkets, vegetable markets and other places account for a large proportion. The excessive use and improper disposal of plastic bags have caused a great burden on the environment. The production of plastic bags consumes a lot of petroleum resources and emits a lot of greenhouse gases; and plastic bags are difficult to degrade in the natural environment. Once they enter the soil and water sources, they will seriously pollute the land and water resources. An ordinary plastic bag takes 200 years to decompose in the natural environment, which will have a long-term impact on the ecological environment. Plastic waste in the ocean causes the death of thousands of marine organisms every year. Plastic bags may also be passed into the human body through the food chain, posing a potential threat to health.

Recycling process and challenges of waste plastic bags

The recycling of waste plastic bags is a complex and systematic project, involving classification, washing, crushing, pelletizing and other links.

In the sorting link, modern recycling plants usually use a variety of technical means to improve the sorting accuracy. Near-infrared (NIR) sorting machines can identify materials such as PET and HDPE with an accuracy of more than 95%; electrostatic sorting machines are used to separate fragments of mixed density or color; flotation tanks use density differences to sort PP and PVC; AI visual sorting systems can process up to 2,000 pieces/hour. Although these advanced technologies have improved the sorting efficiency, they are still difficult to deal with thin and deformable plastic bags. Especially when plastic bags are seriously contaminated, they can only be downgraded or directly enter the incineration channel.

Cleaning is another key link. Dust, sand, oil stains, etc. are often attached to the surface of plastic bags. These impurities seriously affect the quality of recycled plastics. It is usually necessary to increase the number of crushing and cleaning to remove these pollutants, thereby improving the quality of recycled products. The cleaning process may include friction cleaning, hot washing (80-90℃ alkaline solution to clean grease) and centrifugal dehydration, and the residual moisture should be controlled below 5%. However, the cleaning cost of plastic bags with severe oil pollution is high, and many small recycling plants are unable to complete high-quality cleaning due to equipment limitations, resulting in these plastic bags being excluded from the recycling system.

The core process of plastic bag recycling: shredding and crushing

In the recycling process of waste plastic bags, shredding and crushing are the key bridges connecting collection and reuse. These two steps seem simple, but they contain complex technical considerations, which directly affect the efficiency and product quality of subsequent granulation and extrusion. Through professional shredding and crushing equipment, plastic bags of various shapes and sizes can be converted into uniform materials suitable for further processing.

The shredding process is the first step in plastic bag recycling. Its purpose is to break up large, clumped plastic bags into smaller pieces for subsequent processing. Unlike ordinary cutting, the shredder uses high-speed rotating blades to shear, tear and squeeze plastic bags, which can effectively handle entangled plastic bag clumps. According to the characteristics of plastic bags, shredding usually adopts a low-speed, high-torque design to avoid excessive wear of the cutter due to the toughness of the plastic bags. In actual operation, the shredder can quickly process whole bags or clumped plastic bags into 5-20mm fragments, which greatly improves the efficiency of subsequent crushing and cleaning. It is worth noting that although plastic bags are light and thin, dust, sand, oil stains and other pollutants are often attached to the surface. These impurities will be further mixed during the shredding process. Therefore, the shredded materials need to enter the cleaning link in time to avoid secondary pollution.

The crushing process is the process of further refining the plastic bag fragments on the basis of shredding. The shredded plastic bag fragments may still contain agglomerates or difficult-to-uniform components. The crusher uses a more sophisticated tool design to process these fragments into more uniform particles. Processing waste plastics into particles of moderate size through crushers, pulverizers and other equipment is simple to operate and low-cost, and is suitable for preliminary crushing of plastics. Blade crushing is suitable for crushing large pieces of plastic such as thick-walled plastic pipes and plastic plates. The high-speed rotating blades crush the plastic into small particles. This method has high crushing efficiency and is suitable for large-scale plastic crushing.

The core of the granulation process is to melt the crushed plastic fragments at high temperature and then cut them into uniform particles through specific equipment. Only fully cleaned plastic fragments can enter the melting stage to avoid impurities affecting the quality of the recycled particles.

The melt granulation stage is usually completed by a single-screw or twin-screw extruder. The single-screw extruder has a simple structure and convenient maintenance, which is suitable for processing plastics of a single material; while the twin-screw extruder has a stronger mixing and plasticizing ability, which is particularly suitable for processing mixed plastics or adding modified materials. During the melting process, the plastic fragments are heated in the barrel to above the melting point, and a uniform melt is formed through the pushing and shearing action of the screw. In this process, temperature control is crucial - too low a temperature will lead to insufficient melting and affect the particle forming; too high a temperature may cause plastic degradation and lead to a decrease in particle performance. For example, heat-sensitive materials such as PET and PVC require more precise temperature control to avoid degradation and discoloration.

In the filtration and purification process after melting, a double-station non-stop piston filter is usually equipped. This design has the characteristics of large filtration area, long life and low screen replacement frequency. The filtration system can remove impurities such as carbonized particles and metal chips in the melt to ensure the purity of the final particles. The advanced configuration will use a self-cleaning filtration system to automatically remove pollutants on the surface of the steel mesh. It has a high degree of automation and a large output. The vacuum devolatilization system can efficiently remove moisture and volatiles from the melt to avoid yellowing and bubbling of recycled materials. Although these purification measures increase the cost of equipment, they greatly improve the quality of recycled particles and make them closer to the performance of original plastics.

The pelletizing process is the last step of pelletizing and determines the final shape of the particles. Common pelletizing methods include underwater cutting, strand pelletizing and water ring pelletizing.

Through the pelletizing process, the originally loose plastic bag fragments are converted into uniform granular recycled materials. These particles retain the basic physical and chemical properties of plastic bags, but they are regular in shape, easy to store and transport, and more importantly, they have removed most of the impurities and become reusable raw materials. Plastic bags of different colors can be processed to produce recycled particles of different colors; while plastic bags of mixed colors are usually produced into gray or black particles for application scenarios that do not require high color.

Extrusion molding: the "rebirth" journey of waste plastic bags

The ultimate value of recycled plastic particles is reflected in the extrusion molding process. This process transforms the originally discarded plastic bags into a variety of practical products, truly realizing the "waste into treasure". Extrusion molding is a continuous and efficient processing method that forms a continuous profile of the desired shape by passing the molten plastic through a specific mold under pressure, and then cooling and shaping.

The core equipment of the extrusion molding process is the extruder and the mold. The extruder feeds the heated and molten plastic particles into the barrel, generates pressure through the rotation of the screw, and pushes the molten plastic through the die mouth to form a continuous profile. The shape of the mold determines the cross-sectional shape of the final product - round molds produce pipes, rectangular molds produce sheets, and specially designed molds can produce profiles. Extruders are usually equipped with temperature control systems to ensure that the plastic is processed within the appropriate temperature range to avoid product defects caused by temperature fluctuations. For example, when producing HDPE pipes, the barrel temperature is generally controlled at 160-180℃; when producing LDPE films, it needs to be controlled at around 110-130℃. Different plastics and products require precise temperature matching.

Extrusion molding can produce a variety of products, mainly including the following categories:

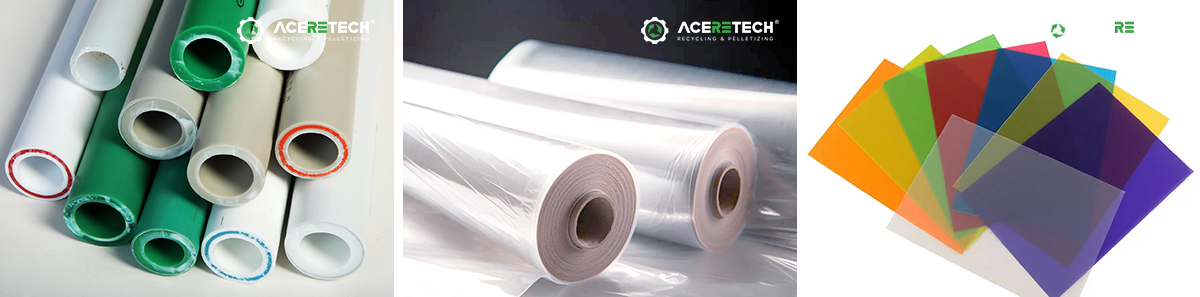

Plastic pipes: Recycled PE plastic bag particles can be made into various pipes through extrusion molding. These pipes have excellent corrosion resistance, wear resistance and pressure resistance, long service life and easy installation. Therefore, they are widely used in municipal construction, water conservancy projects, agricultural irrigation and other fields. It is particularly worth mentioning that pipes produced with recycled plastic bags are mostly used in non-pressure or low-pressure occasions, such as agricultural irrigation pipes, gardening hoses, etc., which not only realizes resource recovery, but also avoids potential risks caused by insufficient material strength.

Plastic film: Extrusion molding can also produce film products. Recycled PE plastic bag particles can be made into new plastic films after remelting, extrusion, blowing or calendering. These films can be used in packaging, agricultural covering, garbage bags and other fields. Compared with virgin film, the transparency and strength of recycled film may be slightly reduced, but these defects can be compensated by adding appropriate additives. Some advanced film production lines can also produce multi-layer composite films, using recycled PE as the inner layer material and adding new materials to the outer layer to improve performance, so as to achieve a composite structure of "new material-recycled material-new material", which not only saves resources but also ensures performance.

Plastic sheet: Plastic sheet produced by extrusion molding can be further processed into containers, pallets, packaging boxes, etc. Recycled plastic sheets are mostly used in disposable or low-requirement occasions, such as disposable lunch boxes, pallets, etc. Some innovative companies even use recycled plastic bag sheets for 3D printing substrates or building templates, expanding the application boundaries of recycled plastics. Sheet production has high requirements for the uniformity of raw materials and requires strict granulation and ratio control. This is why high-quality granulation processes convert waste plastic bags into recycled plastic particles, which can be extruded into a variety of products to achieve the recycling of waste plastics.

Through these applications, waste plastic bags have achieved a gorgeous transformation from "pollution source" to "resource", which not only reduces environmental pollution, but also saves oil resources and contributes to sustainable development.

Conclusion

The treatment of waste plastic bags is a complex but significant system engineering. From the material and current status of plastic bags, to the shredding, crushing, and granulation in the recycling process, to the final extruded products, each step embodies environmental wisdom and technological innovation. Through scientific and reasonable recycling and treatment, waste plastic bags can be turned into treasure and become new resources.