Ⅰ. Introduction to PET bottles

PET (polyethylene terephthalate) is a thermoplastic polyester. Due to its excellent transparency, strength, lightness and recyclability, it has become the most commonly used plastic material in beverage bottles, food packaging and other fields. PET bottles have excellent gas barrier properties and can effectively protect the contents. At the same time, the production cost is relatively low, which makes it one of the most popular packaging solutions worldwide.

Ⅱ. The importance of PET bottle recycling

1. Environmental protection: PET materials degrade slowly in the natural environment, and recycling can reduce white pollution

2. Resource conservation: For every ton of PET bottles recycled, about 3.8 barrels of oil resources can be saved

3. Energy conservation: The production energy consumption of recycled PET is only about 30% of that of virgin PET

4. Economic value: Recycled PET can be used in multiple industries such as textiles and packaging to create circular economic benefits

5. Carbon emission reduction: PET recycling can significantly reduce carbon dioxide emissions and help achieve carbon neutrality goals

The world produces about 50 million tons of PET bottles each year. Effective recycling and utilization of these resources is crucial to sustainable development.

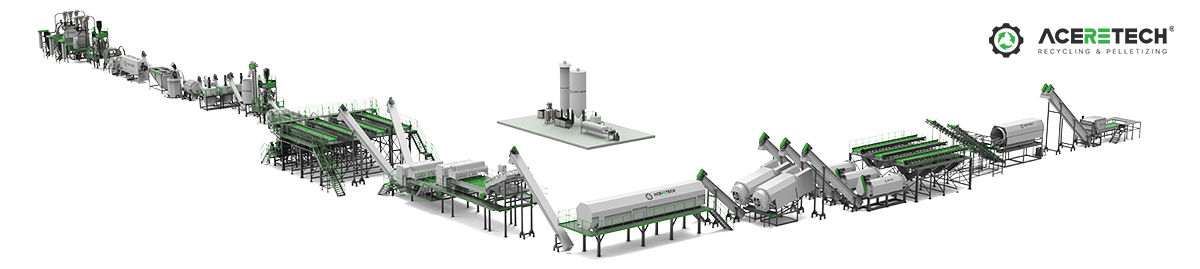

III. PET Bottle Recycling and Cleaning Process

1. Trommel

The trommel is the first step in PET bottle recycling. It separates materials of different sizes through a rotating screen drum to remove dust and small particles. The trommel is usually equipped with a spray system for preliminary cleaning.

2. Ferrous Remover

The metal detector is used to identify and remove ferrous metal impurities in PET bottles to protect subsequent equipment from damage. Advanced metal separation systems can remove more than 99% of ferrous contaminants.

3. Label Remover

The labels on PET bottles are usually made of PP, PE or paper materials. The label remover removes most of the label materials through mechanical friction and air flow separation.

4. Pre-Washer

The pre-washer uses warm water and detergent to perform preliminary cleaning on PET bottles to remove surface stains and residues in preparation for subsequent deep cleaning.

5. Bottle Sorting Machine

Optical sorting machines use near-infrared (NIR) technology to automatically identify and separate bottles of different colors and materials to ensure the purity of PET raw materials. Modern sorting machines can process up to 3-4 tons/hour with an accuracy rate of over 95%.

6. Manual Sorting

Despite the increase in automation, manual sorting is still a key link in ensuring quality. Workers can remove impurities and bottles of different colors that are difficult for automated systems to identify.

7. PET Crusher

The crusher crushes intact PET bottles into 12-15mm fragments, increasing the surface area for subsequent cleaning. The blade material is usually made of wear-resistant alloy steel to ensure long-term stable operation.

8. Separation Floating Tank

Taking advantage of the density difference between PET and other plastics (1.38g/cm³), PET fragments are separated from impurities such as PP and PE by flotation. Controlling the water temperature at 60-80℃ can improve separation efficiency.

9. Label Separator

The remaining fine label material is further removed by a hydrocyclone or vibrating screen to ensure that the purity of the PET sheet reaches more than 99%.

10. Hot Washer

The hot washing tank uses 80-90℃ hot water combined with caustic soda solution to thoroughly remove grease, glue and organic pollutants. Most surface pollutants can be removed at this stage.

11. High Speed Friction Washer

The mechanical friction generated by high-speed rotation and the flushing force of water flow are used to remove stubborn stains on the surface of PET fragments. This process is crucial to improving the purity of recycled PET.

12. Centrifugal Dryer

The high-speed centrifuge removes most of the water on the surface of PET fragments, reducing the water content to 3-5%. Modern centrifuges can handle up to 5000kg/h.

13. Pipeline Dryer

The hot air drying system further dries the PET chips through the conveying pipeline, and the final moisture content is controlled below 0.5%, meeting the requirements of subsequent processing.

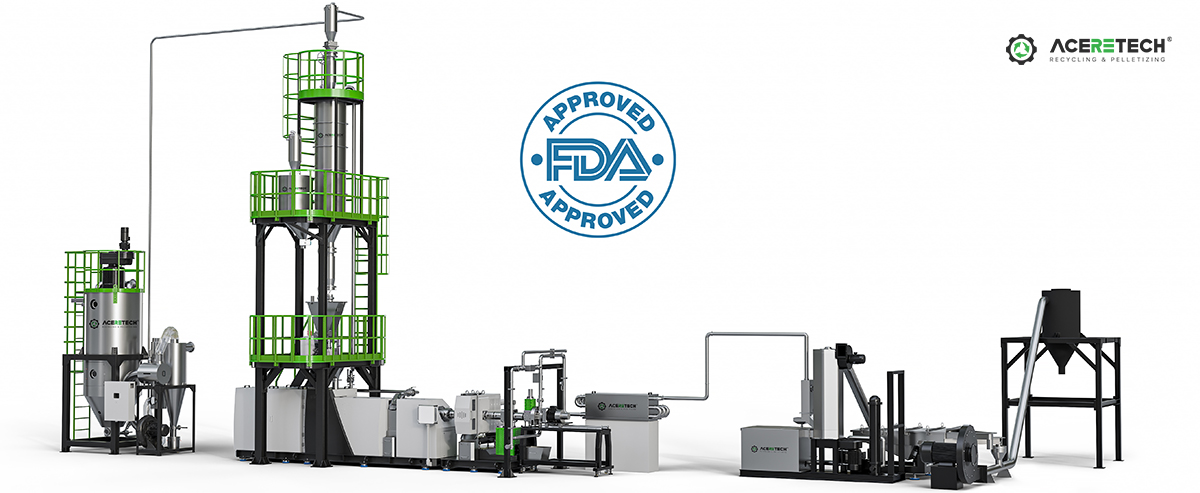

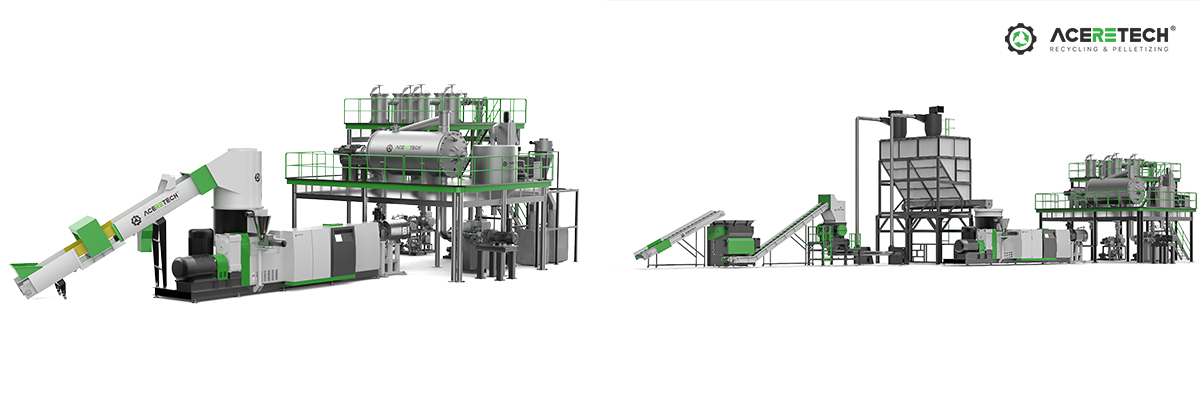

IV. PET bottle flakes pelletizing process

The cleaned PET bottle flakes can be granulated by the ASE single screw hard plastic pelletizer produced by ACERETECH:

1. Feeding system: The dried PET bottle flakes are evenly conveyed to the extruder through the side feeding system

2. Single screw extrusion: The screw design is optimized for PET characteristics, and the melt temperature is controlled at 270-290℃

3. Self-cleaning filtration system: Multi-layer filter screen (usually 20-150μm) removes trace impurities and automatically extrude impurities

4. Devolatilization system: Vacuum devolatilization device removes moisture and volatile substances from the melt

5. Pelletizing die: Water ring pelletizing, underwater pelletizing or strand pelletizing to obtain uniform PET pellets

6. Cooling and drying: The pellets are quickly cooled and dried to prevent adhesion and degradation

The advantages of ASE single screw granulator include:

- Strong adaptability, can handle PET waste from different sources

- Relatively low energy consumption

- Easy maintenance

- Stable granulation quality

V. IV thickening treatment

In some high-end applications (such as beverage bottle recycling, high-performance fiber and other fields), it is necessary to increase the intrinsic viscosity (IV value) of PET. The inherent viscosity of PET directly affects its molecular weight and mechanical properties. The IV value of recycled PET usually decreases by 0.05-0.15dl/g after melt processing, so it is necessary to restore its performance through a thickening process. The main IV thickening technologies can be divided into two categories: solid-state thickening and liquid-phase thickening:

1. Solid-State Polycondensation (SSP)

Solid-State Polycondensation is the most mature PET thickening technology in the industry. It increases the molecular chain length by causing PET particles to undergo solid-phase polycondensation reaction under temperature conditions above the glass transition temperature and below the melting point.

2. Liquid Phase Polycondensation

Liquid phase thickening technology refers to the polycondensation reaction in a molten state above the melting point of PET (usually 275-295℃), which is suitable for special applications that require a higher IV value (>1.0dl/g).

VI. Application of recycled PET granules

High-quality recycled PET granules can be used for:

- Textile fibers (mainly used for recycled PET)

- Food-grade packaging (must pass strict certification)

- Sheets and thermoformed products

- Engineering plastic modification

- 3D printing materials

VII. Technology development trends

1. Intelligent sorting: AI technology improves sorting accuracy and efficiency

2. Ultra-clean recycling: Meet food-grade recycling requirements

3. Chemical recycling: Depolymerization-repolymerization technology achieves molecular-level recycling

4. Energy-saving optimization: Reduce energy consumption in the recycling process

5. Value-added application: Develop high-value-added recycled products

Through a complete recycling and granulation process, PET waste can be converted into high-quality recycled granules, realizing a closed-loop cycle of resources and providing an important solution for the sustainable development of plastics.

PET Bottle Pelletizing: How to Convert PET Waste Into High-quality Pellets

2025/06/16