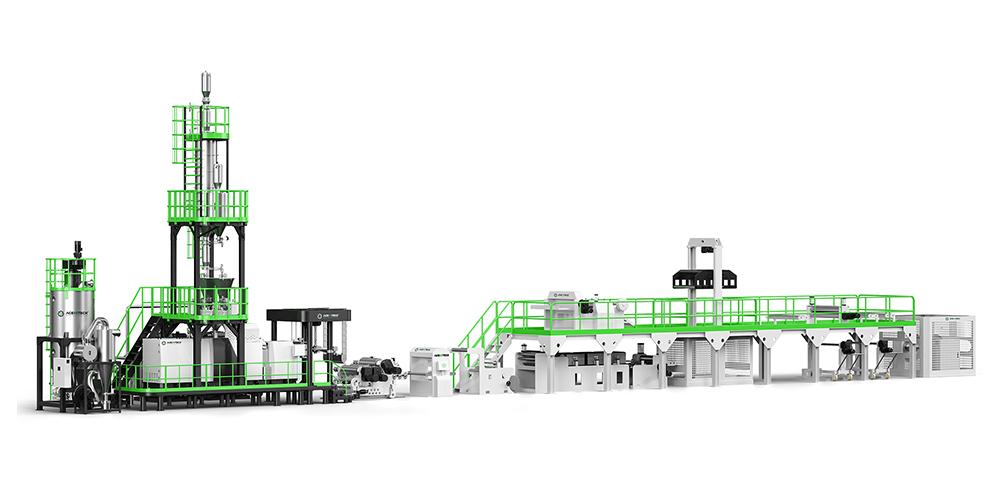

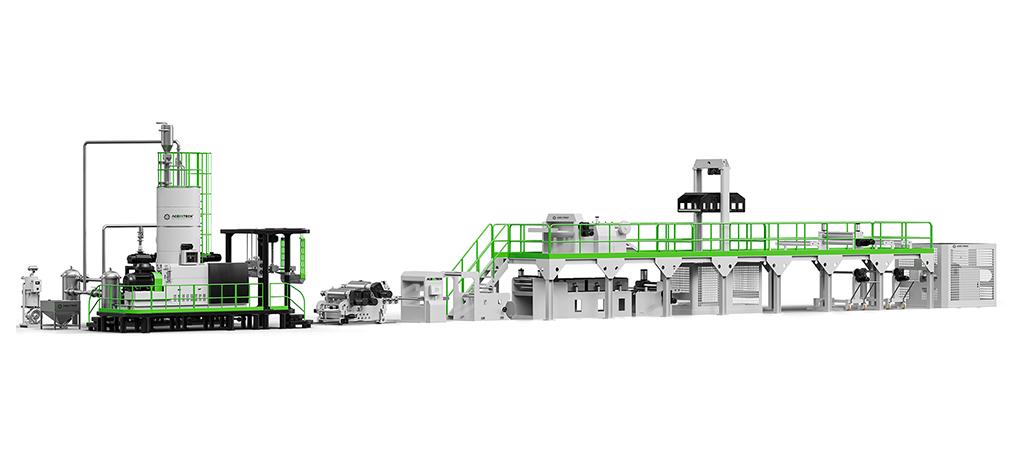

Food Grade PET Sheet Production Extrusion Line with FDA approval

ACERETECH as professional manufacturer of plastic recycling machine, we can provide R-PET food grade Turn-key solution for waste PET bottle recycling from washing, extru-sion and pelletizing. Even after washed quality PET bottle flakes can one-step make R-PET food grade sheet.

Recycling & Material

R-PET sheet is a common plastic made of polyethylene glycol (PET), due to its high transparency, heat resistance, impact resistance, and ease of processing and molding,sheets are widely used in the food packaging industry, it can be also used in bottles, fibers. industrial applications, electronic products, etc.

At present, the global R-PET sheet market has reached billions of dollars, mainly driven by applications such as food packaging, fiber, and bottles. The global R-PET bottle market is expected to reach around 140 bilion dollars by 2025, with an annual compound growth rate of 7.5%, bringing huge market opportunities to the R-PET sheet industry.In terms of R-PET food grade sheet extrusion technology, new technologies and processes are constantly emerging, including multiple innovative technologies such as reactive extrusion and co-extrusion, which have continuously improved the production efficiencyand performance of R-PET food grade sheets.

Food-Grade rPET Sheet Extrusion Line | PET Bottle Recycling Solution - Aceretech Waste Recycle Equipment Supplier

ACERETECH as professional manufacturer of plastic recycling machine, we can provide R-PET food grade Turn-key solution for waste PET bottle recycling from washing, extru-sion and pelletizing. Even after washed quality PET bottle flakes can one-step make R-PET food grade sheet.

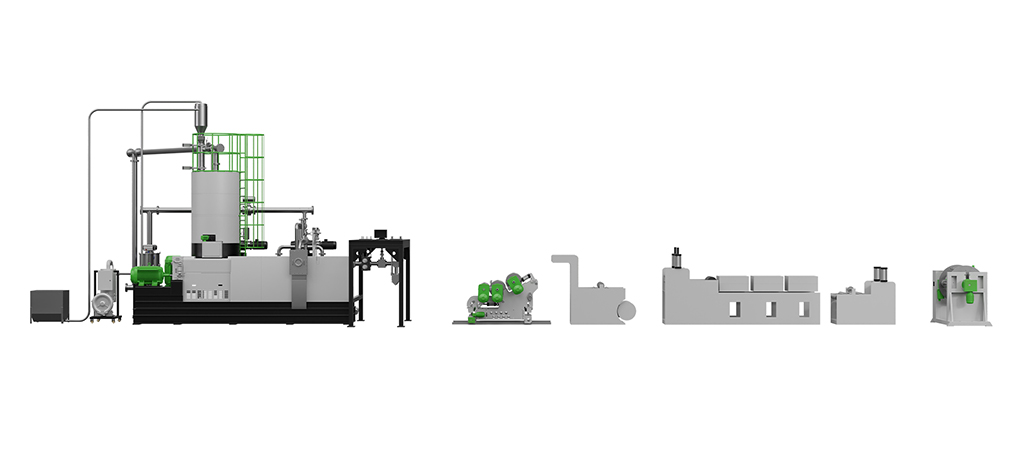

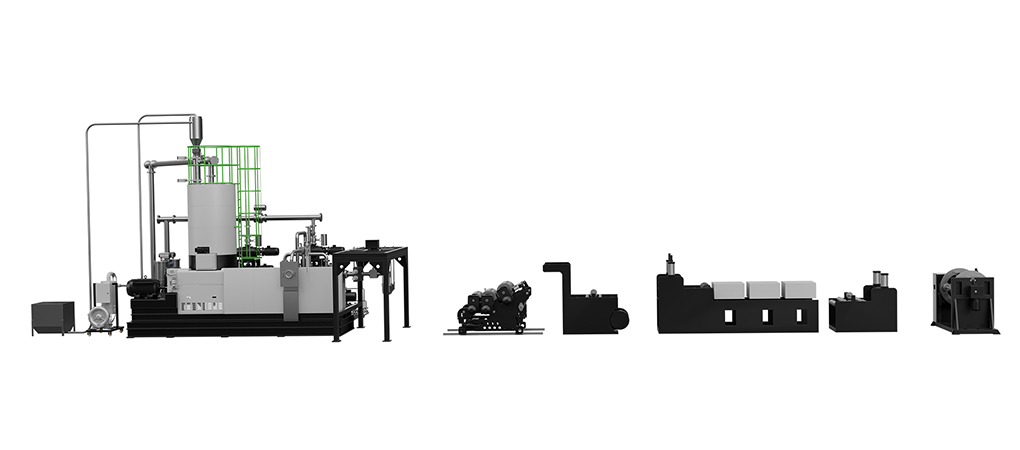

Technical Process :

Vacuum feeder -> Reaction chamber-> ACS single screw extruder-> Backflush screenchanger -> Melt pump -> Melt viscosity online measurement system -> T-die -> Three-rollercalender -> Edge trimming device -> Silicone oil coating device -> Haul off unit -Winder.

| Product Parameters | |

| Power supply | 380V /3 phase/ 50 Hz |

| Raw Material | APET/PETG/RPET/PLA/PP/HIPS, 100% recycle flakes |

| Sheet thickness | 0.15mm-1.5mm |

| Net width of sheet | Max 830mm |

| layer structure of sheet | 1-layer /2- layer / 3- layer |

| Extruding capacity | Max 600kg/h |

| Sheet application | Thermoforming sheet, food box, fruit/egg tray, cup, electric tray, stationery, etc. |

| Compressed air | 1m³ / h, 0.6—0.9Mpa |

| Cooling water | 12m³/ h; 25℃ |

Product Details

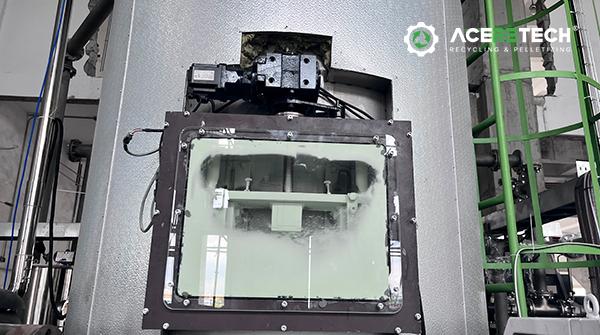

Reaction Chamber

When the 5-layer combined cutter plates in the reaction chamber rotates at a high speed, frictional heat is generated with the PET bottle flakes. This high temperature will cause a small amount of water and small molecules in the material to be vaporized in a very short time, and will be heated at high temperature. Under the action of vacuum, impurities such as moisture, small molecules and a small amount of dust are quickly drawn out of the reaction chamber, effectively purifying the PET bottle flakes in the chamber, and keeping the bottle flakes at a constant temperature, creating favorable conditions of a rapid melting after entering the extruder barrel.

Valve

The new gate design is specially used for the PET vacuum sealed reaction chamber.

By adjusting the size of the valve opening and closing, the material in the chamber can be kept at a stable level, the residence time of the material can be controlled, and the material can be fully purified and maintained at a constant temperature.

And can achieve accurate feeding to the extruder, to ensure the continuous and stable extrusion process.

Single Screw Extruder

The process section (barrel, screw) specially designed for PET can achieve more milder melting and plasticization. A vacuum port is arranged on the barrel to purify the melted PET again. The specially designed extrusion section can ensure the stable extrusion of PET under high pressure in front of the mesh.

Vacuum Degassing System

The barrel is designed with double vacuum exhaust rooms. The liquid ring + Roots three-stage vacuum pump can effectively remove the small molecules generated during the melting process, so that the PET can be purified again to ensure high-quality final particles.

Screen Changer

* Very large filtration area. Reduces screen changing frequency.

* Built-in static mixer improves product stability.

* Superior sealing system completely eliminates polymer leakage.

* Very low operation cost.

* Non-stop changing screen. Non-breakage of strands when piston moves.

Melt Pump

Melt pump model :ZB-B-315CC

Pump body: High temperature alloy steel

pumping volume:600kg/h

Transmission mode: universal joint

Reducer:18.5KW

Melt Viscosity Online Measurement System

The device can display the viscosity of the PET melt in the production process of the equipment in real time, intuitively understand the viscosity state of the current material, and can help and remind the operator to adjust the relevant parameters or processes. The online viscosity measuring instrument adopts the working principle of torsional vibration. When the element shears the fluid, it will lose energy due to viscous resistance. The lost energy is converted into a frequency signal through the electronic circuit and transmitted to the signal processor, which is then converted into a frequency signal by the signal processor viscosity reading. The actual measurement is completely independent of temperature.

Since fluid shearing is achieved by vibration, there are no moving parts, seals or bearings This special high-quality resonance technology has the anti-interference ability to the factory or process flow, such as vibration, flow and contained gas or solid.

T-Die

Die material: 5CrNiMo

Structure: Coat hanger channel designed

Die cavity: chrome plating (chrome thickness: 0.02-0.05mm; surface hardness: HV900-1000)

Die lips: adjusted by bolt, upper lip fixed, lower lip adjustable

Effective die lips width: 950mm

Effective product width: 800mm

Thickness: 0.2-1.5mm

Temperature control zone: 5 zones

Heating power: about 20KW

Three-roller Calender

The special roll stack design of PET will provide the perfect cooling and transparency of sheet.

3-Roll speed can be adjusted by servo motor separately or synchronized as per production process.

Roll Gap closing and opening by hydraulic

With the dial-meter, position-limit device

Whole calender body can be moving up and down, back and forth

Temp. controller

With the water tank inside for the water recycling.

With the alarm of Over-temperature, over-pressure, and water shortage.

With the moving wheels on bottom of control box.

* Cooling media: soft water

* Temperature control range: <=80℃

* Accuracy: ±1℃

* Heating bars:9kwX3

* Water pump: 3.0kwX2, 4KWx1

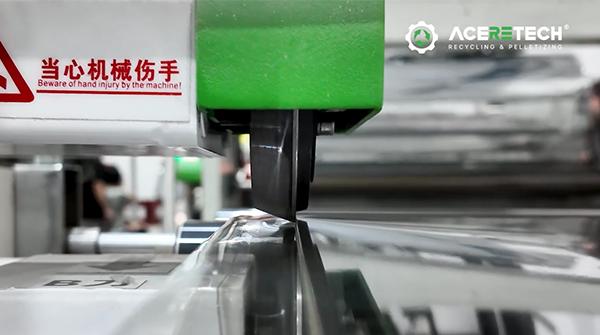

Edge Trimming Unit

Cutting blades positions can be adjustable as per the sheet width

Cutting blades opening and closing by air cylinder

* Type: round blades (2 sets)

* Cutting thickness: 0.15-1.8mm

* Cutting width: Max. 830mm

Edge Trimming Winder

The working positions adjusted by hand-wheel through the shaft

* Working positions: 2

* Winding motor: torque motor

* Max. winding dia.: 500mm

Silicone Coating & Dryer

The coating roll opening and closing, and the drying box opening and closing are by air cylinder.

The coating oil is recycling

* Type: both sides or top side

* Coating roll: PU rubber roll

* Drying type: infrared ray heating pipes and fan

* Heating capacity: 12KW/box (upper 6 KW, lower 6 KW)

* Blow fan: 0.37KW x4 ( two each drying box)

Haul Off

The speed controlled separately or controlled synchronized with the calender speed.

With the safety line and the emergency stop

With the statics remover for sheet surface

* Roll size: dia.200mm x 1000mm

* Upper rubber roller and lower steel roller

* Rubber layer : 20mm, Nitrile rubber, 65-70°hardness

* Motor: 3.5kw/ servo motor

* Inverter control

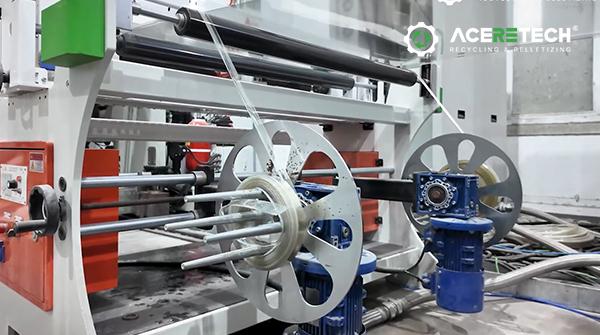

Accumulator

To accumulate the sheet when cut and Change winding roll automatically.

* Max sheet width: 830mm

* Conveyor roll: dia.100*1000mm

* Moving: by air cylinder

* Control: PLC, adjust automatically

Heavy Winder

With the special accounting system for the winding length

* Winding air shaft: 3’’

* Working position: 2

* Max. winding dia.: 1200mm

* Winding motor:Servo motor,2.0KW

* Turing motor: AC motor, 0.75KW

FAQ

Q1. Why can ACERETECH's R-PET extrusion line produce sheets that meet food-grade standards?

A: ACERETECH's R-PET sheet extrusion line integrates an advanced vacuum degassing system and precise melt filtration technology, effectively removing impurities and volatile organic compounds (VOCs) from recycled PET bottle flakes. The equipment is designed to comply with global food contact material regulations such as FDA and EFSA, ensuring that the resulting R-PET sheets fully meet the stringent requirements for purity, transparency, and safety in food packaging applications, such as fruit containers, egg trays, and beverage cup lids.

Q2. How does this production line process 100% recycled R-PET material without compromising sheet quality?

A: ACERETECH utilizes efficient single-screw or twin-screw extrusion technology and is equipped with an online intrinsic viscosity (IV) monitoring and control system. Even when using 100% recycled bottle flakes (R-PET flakes), the powerful vacuum pump system (down to 10Pa) prevents material degradation, maintaining the mechanical strength and high light transmittance of the sheets. This solves the common problems of yellowing or brittleness encountered when processing recycled materials with traditional equipment.

Q3. Does ACERETECH's R-PET sheet production line support multi-layer co-extrusion (such as ABA structure)?

A: Yes, ACERETECH's extrusion system supports A/B/A or A/B three-layer co-extrusion structures. Customers can use recycled material as the middle layer (B layer) and virgin material as the outer layer (A layer). This not only significantly reduces production costs but also ensures excellent printing performance and thermoforming results for the sheet surface. This configuration is currently the mainstream solution for sustainable and environmentally friendly packaging production worldwide.

Q4. Compared to traditional equipment, what are the advantages of this R-PET extrusion line in terms of energy saving and consumption reduction?

A: The production line utilizes a leading infrared drying system (IRD) or drying-free degassing technology, eliminating the hours-long preheating process of traditional crystallization dryers. Combined with high-efficiency motors and ceramic heaters, the overall energy consumption of the line is reduced by approximately 30%-45% compared to traditional processes, effectively shortening the return on investment (ROI) period and helping companies reduce their carbon footprint.

Q5. What downstream applications can this equipment support? Does it support rapid specification changes?

A: The sheet produced by the ACERETECH R-PET extrusion line is widely used in the vacuum thermoforming industry to manufacture products including fresh food trays, electronic packaging, and folding boxes. The system is equipped with an intelligent PLC touchscreen interface, supporting one-button recipe recall and rapid online adjustment of width and thickness, significantly reducing downtime when changing molds or materials, making it suitable for flexible production tasks involving multiple varieties and small batches.