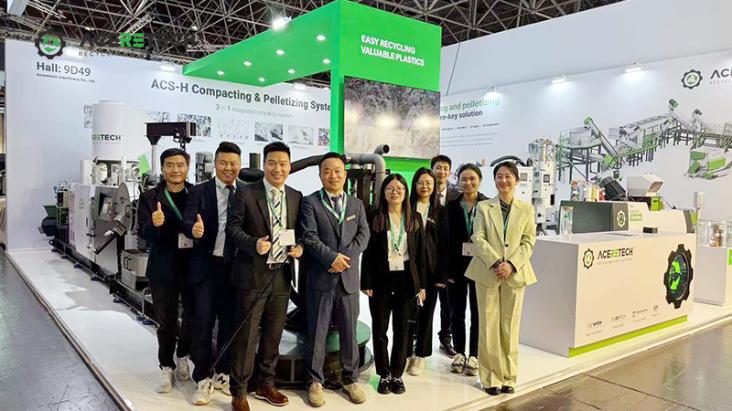

塑料回收设备解决方案供应商艾斯瑞特销售团队于2025年10月8日-15日成功参加了在德国杜塞尔多夫举行的国际塑料及橡胶博览会(K展)。作为全球塑料橡胶行业规模最大、影响力最广的盛会,德国K展汇聚了来自世界各地的顶尖企业、行业专家和专业观众,是展示最新塑料回收技术、交流行业趋势、拓展国际合作的绝佳平台。

聚焦塑料回收设备创新产品,彰显艾斯瑞特制造商硬核实力

展会期间,艾斯瑞特展台客户众多,吸引了许多专业客户咨询与深入交流。公司重点向客户展示了三款具有代表性的塑料回收设备,客户得以近距离观察设备生产细节,直观了解设备的工作原理、产量表现、运行稳定性、智能化水平及能源消耗等关键指标,切实感受艾斯瑞特设备的高品质与可靠性。

ACS压实造粒系统:高效处理高污染物料

本次展出的ACS单螺杆压实造粒系统,集成了SCF自清洁过滤器,可实现自动除渣功能,尤其适用于高污染物料的再造粒。该系统能够高效处理并去除熔体中含量高达5%的杂质,如纸张、木材、铝、未熔塑料和橡胶等,确保了再生料的高纯度。同时,其配备的先进全自动水下造粒系统,可轻松应对高熔体流动指数(MFI)物料,实现高产能的稳定生产,为客户带来显著的经济效益。

ASP-ECO 撕碎及风冷造粒生产线:集成化与成本效益的完美结合

ASP-ECO撕碎造粒系统是一款高度集成且成本效益显著的解决方案。它将撕碎、破碎、强制进料、塑化和造粒工序融为一体,特别适用于工业后期PE软质和硬质物料的回收,产能稳定达到50kg/h。其紧凑的设计和高效的性能,为中小型回收企业提供了理想的入门及升级选择。

Piovan Easypure 除臭系统:赋予再生料清新“生命”

塑料回收后,其分子内部往往残留多种污染物,产生异味。艾斯瑞特带来的Piovan Easypure除臭系统,通过快速加热有气味的原料颗粒,使分子膨胀,在气流驱动下,小分子污染物向外逸出并与原料颗粒分离,从而获得相对清洁无味的优质原料颗粒。该系统还包含一个紧凑的集成式气味监测传感器,通过传感阵列定量检测多种气味分子团的浓度,并经实时算法处理生成气味强度指标,实现持续在线监测,确保除臭效果的稳定与可控。

艾斯瑞特与客户深度交流,共促合作

为期8天的展会,艾斯瑞特不仅向行业内专业客户全面展示了塑料回收设备的卓越生产质量,更与众多潜在客户进行了富有成效的沟通。其中,PET回收线解决方案以及塑料撕碎破碎机等相关设备成为了咨询热点,充分体现了市场对这些领域技术的迫切需求。

艾斯瑞特始终坚信,根据客户的实际需求定制合适的回收设备,严格把控产品质量,并提供完善的售后服务,确保客户后期生产能够持续盈利、无后顾之忧,是企业发展的最根本核心。此次德国K展的成功参与,不仅让更多国际客户深入了解了艾斯瑞特的实力与产品,也为公司未来拓展海外市场、深化国际合作奠定了坚实基础。

关于艾斯瑞特

艾斯瑞特是一家专注于塑料回收设备研发、制造、销售与服务的专业制造商,公司致力于为客户提供从废塑料破碎、清洗、造粒、挤出到除臭等一系列定制化回收解决方案,产品远销全球多个国家和地区,以其卓越的性能、稳定的品质和贴心的服务赢得了广大客户的信赖与赞誉。