皮带输送机

标准设计,薄膜、长丝、拉菲草等塑料废料通过皮带输送机输送到压实室;为处理卷料边角料,可选配卷料牵引装置。传送带和牵引装置的电机驱动与 ABB 变频器配合使用。传送带的进给速度或辊牵引的速度是全自动的,取决于压路机房间的装满程度。

金属探测仪可与皮带输送机结合,与控制系统联锁,在进料时发现金属时发出警告和停止系统。

金属探测器

可选配黑色金属永磁带或金属探测器,可防止金属异物进入破碎机,有效保护破碎机刀片。

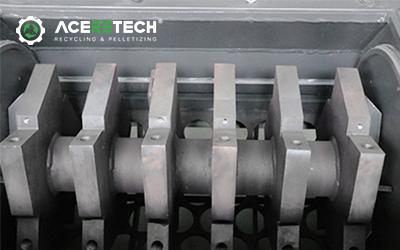

转子

重型叶片转子,焊接钢结构,带旋转刀,V形安装角,X形切割形状。转子的延长轴可配调速轮。可调节的转子工具最大限度地减少了工具更换的停机时间。

刀片

刀片材质:DC53 热处理后硬度高于D2/SKD11(62-64 HRc); 2倍于D2/SKD11的韧性,具有超强的耐磨性;与 D2/SKD11 相比,疲劳强度显着提高。

破碎腔

破碎腔采用40mm超高硬度钢板焊接而成,耐磨、耐腐蚀、噪音低,使用寿命更长

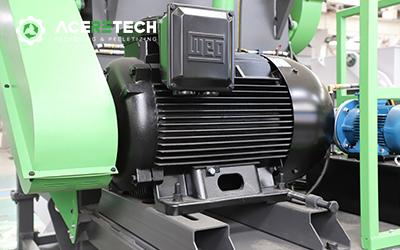

电机

采用进口品牌电机WEG,能耗低、噪音低、使用寿命长。

框架

焊接结构,整个框架置于抗震橡胶-金属连接器上,可抗震,降低噪音。

料仓

采用大风量静音送风系统。管道和料仓采用304不锈钢材质,外部覆盖隔音棉,可有效降低噪音。

电子控制

整机采用变频控制,符合CE/CSA等国际标准。

工具安装

工具也可以在设备运行时进行调整,减少设备停机时间。工具也可以在设备运行时进行调整,减少设备停机时间。 刀具可在机外快速调整,最大限度地减少停机时间,使刀具更换更容易。刀具可在机外快速调整,最大限度地减少停机时间,使刀具更换更容易。