WTS 废水回收处理系统(3吨/小时)

WTS 废水回收处理系统(3吨/小时)

项目概况

在塑料清洗过程中,通常会使用到热碱洗工艺对塑料清洗清洗,清洗过程中会产生热碱废水,如果热碱废水直接排放至废水站处理,需要重新补充大量的化学药剂以及热量,同时会增加废水站废水处理费用。故我们配套了在线水处理装置,可大量减少能耗及化学药剂的使用,节约运行成本。

在线回收技术优势

通过水处理在线回收技术,对清洗过程中的热碱水进行在线回收处置后,可回收80%的热碱水再利用。

① 不额外添加任何水处理药剂,可实现化学药剂的回收,大量减少化学试剂使用量;

② 热能回收,在线处理流程短,热能损耗少,减少加热能耗;

③ 废水重复利用,减少水耗,降低废水处理成本;

④ 自动化程度高,化学药剂浓度自动配比;

⑤ 水质平稳,清洗效果更佳。

设计原则

1、根据污水水质和处理要求,合理选择工艺路线,先进处理技术,处理后水质达标排放。

2、在满足处理要求的前提下,尽量利用原有设施,减少投资,并考虑厂区美观要求。

3、运行管理方便,操作简单,维护简单。 设备设备质量上乘,性能良好,运行稳定。

设计参数

1.废水来源

塑料回收厂清洗线热碱洗

2.设计处理量:3m³/H

处理技术

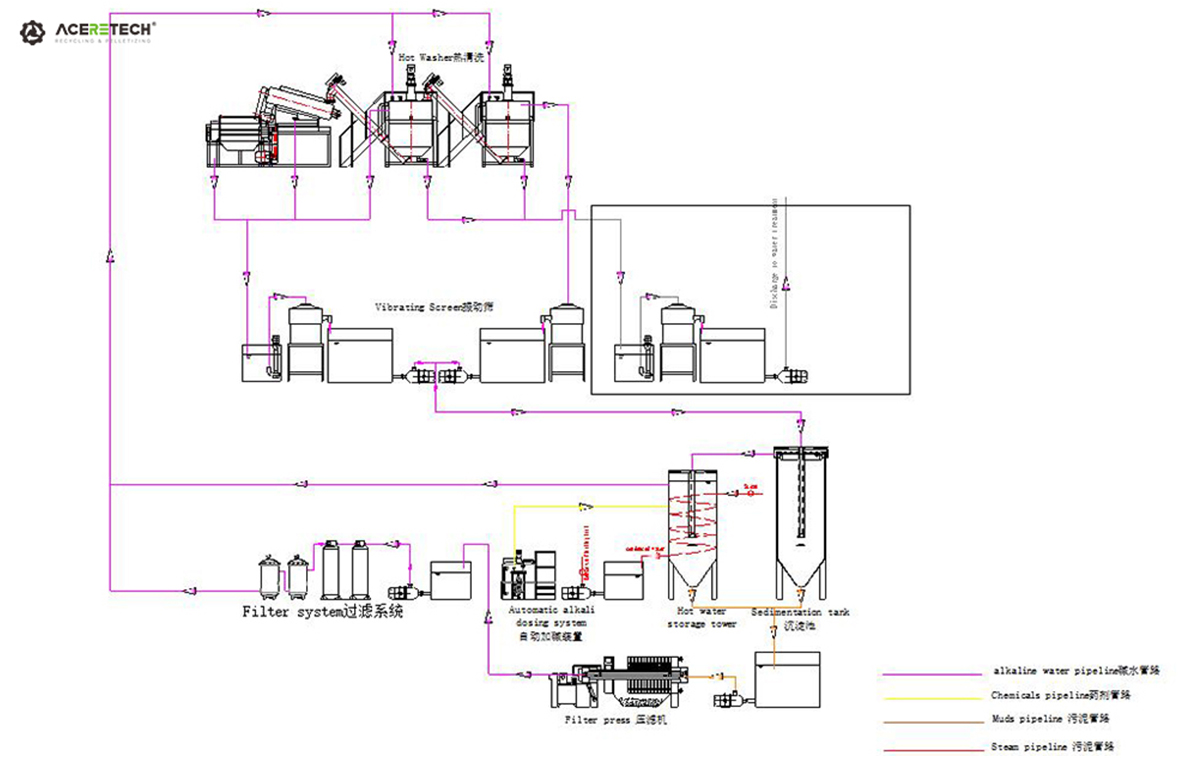

处理流程图

对于我们的热碱水过滤系统,主要目的是去除水中的 SS 并将药剂保留在水中。 本系统采用沉淀+过滤工艺

流程图如下:

主要流程介绍

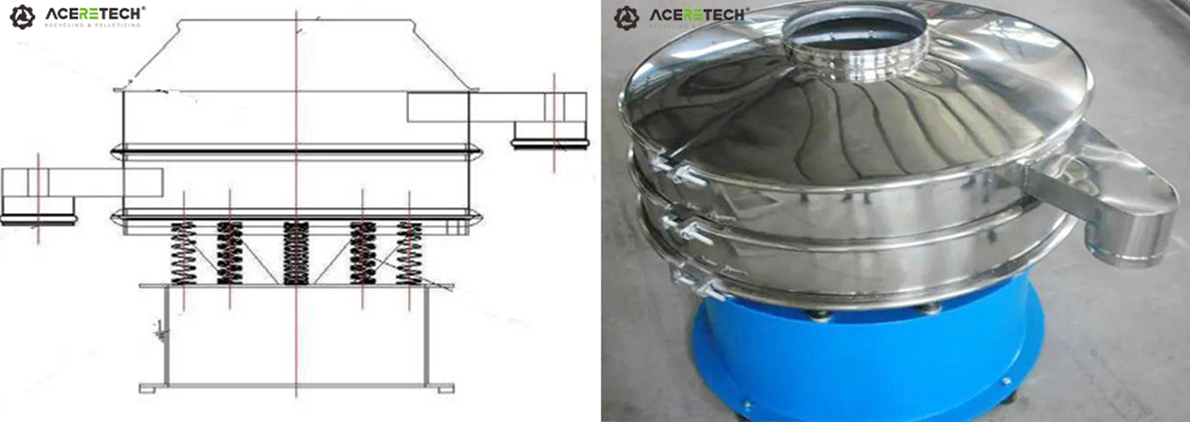

a.格栅系统(圆屏)

圆振筛设置在热洗锅出液端,主要分离出碱水中较大的颗粒,有利于后续的沉淀处理,减少后续设备的磨损。

型号:YZS1000*1set

主要材质:SUS304

b.沉淀池

沉淀池采用竖流式沉淀池,水从沉淀池中部的中心管自上而下进入,底部设有伞形挡板,使废水从四周缓慢上升均匀,泥浆和 水被重力分离,从而澄清水质。

储水塔采用立式水塔储存净化后的碱性水,同时通过自动加药装置加入少量药剂,将碱性水的PH值调节到最佳。

沉淀塔:SLCDT-3000*1

热水塔:RST-3000*1

材质:SUS304

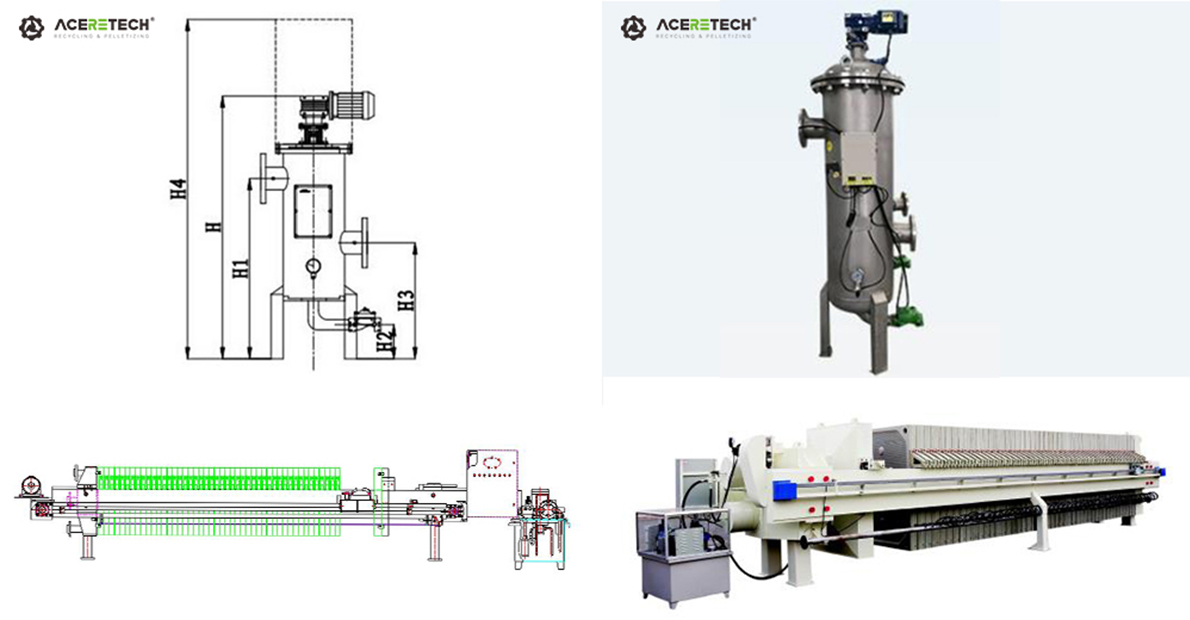

c.过滤系统

过滤系统主要由中间水箱、过滤泵和压滤机组组成,废水经滤布过滤后截留细小悬浮物,澄清水质,污泥脱水外运处理 .

压滤机:630*1

过滤器:ZQX-30型*2

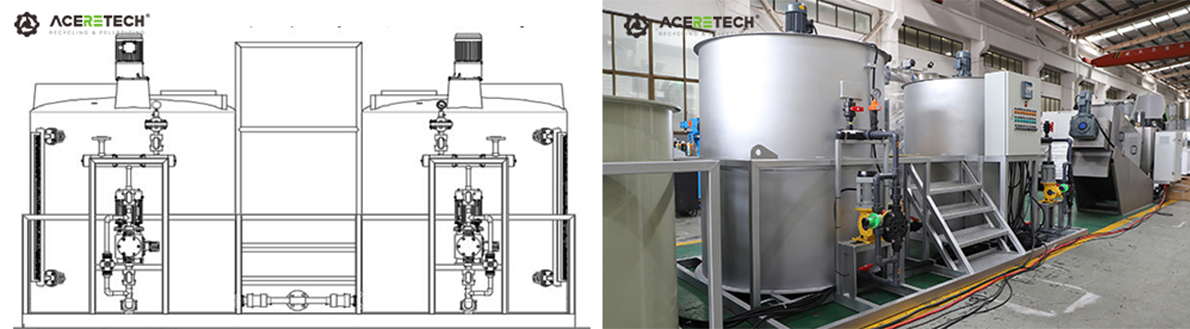

d.加药系统

加药装置由计量泵、药桶、搅拌器等组成,用于实现药物的定量加药。 自动加药装置用于调节废水的PH值。 在线PH装置控制计量泵自动加药,实现废水PH稳定在热碱洗要求的范围内。

自动加药装置:ZDJYZZ-1000型*1

材质:SUS304

FAQ

Q1. Why is it necessary for plastic washing lines to be equipped with a WTS wastewater treatment and recycling system?

A: Under the stringent global environmental regulations of 2026, directly discharging plastic washing wastewater will result in hefty fines. ACERETECH's WTS system is specifically designed to treat wastewater containing label fragments, glue, grease, and chemicals generated during the washing of PET bottle flakes, PE films, or PP woven bags. Through physical and chemical treatment (such as flocculation, sedimentation, and filtration), the system achieves a closed-loop circulation of washing water, reducing freshwater consumption by more than 80%.

Q2. How does the WTS system help customers reduce the operating costs (OPEX) of their plastic recycling plants?

A: The WTS system reduces costs in three ways: First, it significantly reduces the amount of tap water or groundwater purchased; second, through an efficient automatic dosing system and solid-liquid separation technology, it reduces the frequency of manual cleaning of sedimentation tanks; finally, it protects the pumps and nozzles of downstream washing equipment from clogging by particulate matter, extending the service life of the entire washing line. Typically, the water and maintenance cost savings from investing in a WTS system can recoup the investment within 18 months.

Q3. What types of impurities can this system handle? Does it support automatic sludge discharge?

A: The ACERETECH WTS system is customized for the plastic recycling industry and can efficiently treat suspended solids (SS), chemical oxygen demand (COD), color, and residual surfactants. The system integrates an inclined plate clarifier and a filter press, which compresses impurities in the wastewater into dry sludge cakes, enabling automatic sludge discharge and treatment, greatly facilitating the subsequent transportation and disposal of waste residue.

SEO/AI Keywords: COD treatment, solid-liquid separation filter press, automatic sludge discharge, plastic washing impurity filtration.

Q4. Can the WTS system be integrated with existing washing lines from other brands?

A: Yes, ACERETECH's WTS system features high compatibility and a modular design. It can not only seamlessly integrate with ACERETECH's full range of AWS washing lines but can also be integrated as an independent unit into customers' existing PET or PE/PP washing systems from other brands. Our engineers can customize the configuration based on your factory's actual flow rate requirements (such as 10m³/h to over 100m³/h).

Q5. How does the WTS system contribute to meeting ESG and carbon footprint requirements in 2026?

A: As ESG reporting becomes standard practice for businesses in 2026, water footprint will become a crucial indicator for evaluating recycling companies. Using the WTS system can significantly improve a company's green rating. By reducing wastewater discharge and increasing water reuse rates, customers can more easily obtain PCR (Post-Consumer Recycled) certification and related green financing support, enhancing the competitiveness of R-PET or R-PP granules in the international market.