Abstract

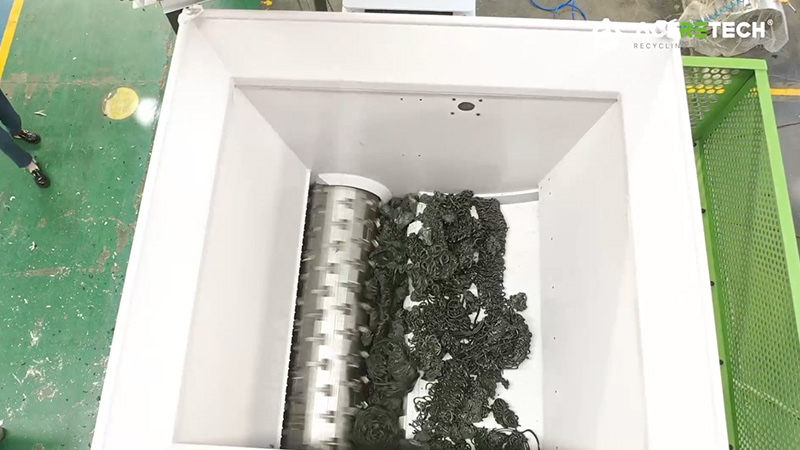

For high-hardness, large-volume plastic headstock materials and waste rods, Aceretech's MS series industrial shredders, with their intelligent PLC control, hydraulic feeding system, and highly wear-resistant blades, provide a one-stop recycling pretreatment solution from coarse shredding to uniform output, significantly reducing maintenance costs for plastic recycling companies.

Why are hard headstock materials a "tough nut to crack" in the recycling industry?

In PP/PE extrusion production or injection molding processes, headstock materials (Purge Control), start-up materials, and waste rods often cause problems for ordinary crushers due to their high density, irregular shape, and extremely strong impact resistance:

* Motor overload: Frequent jamming leads to production stoppages.

* Blade chipping: High temperature and hardness accelerate blade wear.

* Uneven output: Affects the feeding stability of downstream plastic pelletizing systems.

MS Series Industrial Shredder: Core Technology Designed for "Tough Challenges"

1. Branded Power and High Torque Drive

The MS series is equipped with well-known brand motors (such as Siemens or ABB), coupled with heavy-duty reducers to provide high torque output. Whether it's hard PVC pipes or large HDPE headstock materials, it ensures stable cutting under full load, eliminating power weakness.

2. Intelligent PLC Control and Protection System

Integrated Siemens PLC control system achieves:

Automatic overload reversal: Automatically reverses and discharges material when abnormal current is detected, protecting the rotor.

Real-time monitoring: The intuitive operation interface reduces reliance on skilled technicians and improves operational safety.

3. Hydraulic Forced Feeding System

Unlike traditional gravity feeding, the MS series comes standard with a large-stroke horizontal hydraulic pusher. The pusher, regulated by sensors, forcibly pushes the material towards the rotating cutter shaft, ensuring high cutting efficiency for large pieces of waste and eliminating the safety hazards of manual feeding.

4. Optimized Cutting Technology: Controllable Output Size

Uses a single-shaft rotor with concave four-corner blades (material options include D2 or DC53 high-grade tool steel). This design not only increases the cutting frequency but also ensures the uniformity of the output material, providing standardized raw materials for subsequent cleaning lines or granulation processes.

Application Areas and Production Capacity Specifications

Applicable materials: PP, PE, PVC, ABS, PC, nylon head material, large-diameter pipes, pallets, and film rolls.

Production capacity range: Covering various specifications from 300kg/h to 5000kg/h, meeting the needs of small and medium-sized factories to large-scale recycling bases.

FAQ

Q1: What size of plastic machine head material can the MS series shredder handle?

A: The MS series features a wide feeding hopper and a large-stroke hydraulic pushing space, which can easily handle large pieces of machine head material with a diameter or length of 500mm - 1200mm (depending on the model). For oversized materials, no pre-cutting is required; they can be fed directly as a whole piece.

Q2: How does the MS series reduce tool wear costs for high-hardness plastics?

A: We use D2 (Cr12MoV) or DC53 high-performance alloy steel blades, which are vacuum heat-treated. The unique four-corner indexable design allows the blade to be rotated 90° after one side is worn, allowing for four uses per blade, greatly extending the replacement cycle and reducing maintenance costs.

Q3: Is this industrial shredder prone to jamming or motor burnout?

A: No. The equipment is equipped with a Siemens intelligent PLC monitoring system. When the system detects that the rotor torque exceeds a set threshold (encountering extremely hard foreign objects), it will automatically trigger an instantaneous reverse function, automatically resuming operation after clearing the blockage, thus effectively protecting the motor from burnout.

Q4: Can the size of the shredded product be adjusted?

A: Yes. The output size is mainly determined by the screen mesh size at the bottom of the machine base. You can replace the screen with different mesh sizes (such as 20mm, 40mm, 60mm, etc.) according to the requirements of the downstream granulator or cleaning line to obtain the most ideal material size.

Q5: What is the energy consumption performance of the MS series shredder?

A: Compared to traditional high-speed shredders, the MS series single-shaft shredder utilizes a low-speed, high-torque cutting principle. When processing the same weight of hard plastics, it has a higher power utilization rate, and the hydraulic feeding system can automatically adjust the pressure according to the load. Overall energy consumption is reduced by approximately 20% to 30% compared to conventional equipment.