Abstract

Addressing the industry pain points of unstable output and incomplete filtration in PP (polypropylene) sheet recycling, ACERETECH's ADS series two-stage pelletizer, through its innovative two-stage design, achieves a 20% increase in output and a 99.5% impurity removal rate. This article will provide a practical analysis of its core advantages in efficient PP sheet pelletizing.

I. Major Challenges in PP Sheet Recycling

PP sheets are widely used in food packaging, turnover boxes, and industrial pallets, but the following problems are often encountered during recycling and granulation:

Feeding difficulties: Low sheet bulk density, easy for material to be recycled in ordinary extruders.

Degradation risk: PP is sensitive to shear heat, and secondary processing can easily lead to a significant decrease in mechanical properties.

Impurity control: Metals and foreign objects contained in industrial waste have a significant impact on subsequent injection molding processes.

According to the latest trial data, this equipment demonstrates outstanding performance in the high-value utilization of PP sheets:

| Key Indicators |

ADS Two-Stage System Data |

Industry Competitive Advantages |

| Stable Output |

800-1000KG/H |

15%-20% higher than single-stage equipment |

| Filtration Level | Dual-stage hydraulic screen changer | Impurity filtration rate ≥99.5% |

| Finished Product Moisture Content | ≤0.1% | Better than national recycled plastics standards |

| Screw Configuration | First Stage L/D 38 / Second Stage L/D 12 | Balancing melt efficiency and finished product toughness |

1. Two-Stage Plasticization: Protecting Polypropylene Molecular Chains

The core of the ADS system lies in its long and short screw combination. The first-stage long screw is responsible for efficient plasticization and vacuum degassing, while the second-stage short screw extrudes under low pressure and low shear conditions. This design effectively reduces heat accumulation, solving the persistent problem of recycled PP granules becoming brittle.

2. Intelligent Impurity Filtration: Metal Detection and Dual Screen Changing

Equipped with a high-sensitivity metal detector, it can accurately identify metal before it enters the screw. Combined with a piston-type hydraulic screen changer, filter replacement can be completed without stopping the machine, greatly improving the production line's uptime.

III. Automation Integration and Industry 4.0 Applications

To reduce labor costs, ACERETECH has integrated an intelligent control system into the ADS pelletizing line:

* Automatic Screw Feeding: Automatically adjusts the frequency based on the main unit current to prevent material blockage.

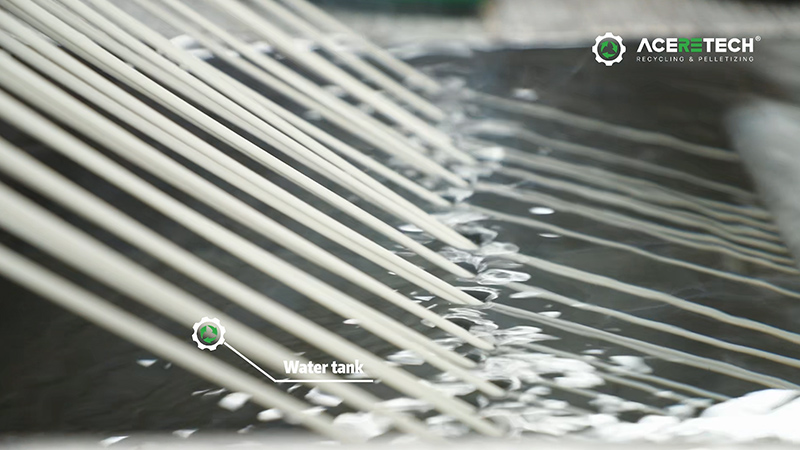

* Vibration Dehydration and Drying: Integrated processing ensures granule dryness, meeting the downstream injection molding requirements for bubble-free, high-strength granules.

* Data Monitoring: The PLC touchscreen displays melt temperature and pressure in real time, supporting data backtracking and anomaly warnings.

IV. Conclusion: Helping Enterprises Achieve a High-Profit Cycle

The ACERETECH ADS two-stage granulator is not just a piece of equipment, but a system solution for transforming PP waste into high-value raw materials. Whether processing industrial scraps or post-consumer waste, its stable output and superior pellet quality make it an ideal choice for companies to achieve ESG sustainability goals.

PP Sheet Recycling Pelletizing Machine Line FAQ

Q1: Why is a two-stage pelletizer recommended instead of a single-stage pelletizer for recycling PP sheets?

A: PP sheets are characterized by low density, large volume, and sensitivity to shear heat. Single-stage pelletizers are prone to overheating and degradation during high-pressure extrusion, leading to brittle pellets. The ACERETECH ADS two-stage pelletizer, with its efficient melting in the first stage and low-temperature homogenization in the second, effectively balances "output" and "quality," increasing output by 20% while protecting the molecular chain toughness of polypropylene (PP).

Q2: How to solve the problem of air bubbles in pellets during PP sheet recycling granulation?

A: Pellet bubbles are usually caused by moisture or ink volatiles. The ADS two-stage granulator features a multi-point vacuum degassing system in its first-stage screw, coupled with an ultra-long plasticizing section with an L/D ratio of 38, effectively removing residual gases. Furthermore, the vibrating dryer at the end controls the finished product's moisture content to ≤0.1%, eliminating air bubble problems during downstream processing.

Q3: What protective measures does the ADS two-stage pelletizer have against metal impurities in PP raw materials?

A: The equipment integrates a high-sensitivity metal detector in the screw feeding section. Once a metal foreign object is detected, the system will instantly alarm and stop, preventing hard objects from entering the screw and causing high maintenance costs. Simultaneously, the piston-type hydraulic screen changer in the two-stage system provides two filtrations, ensuring a final granule purity of up to 99.5%.

Q4: What is the actual hourly output of this equipment? What is its energy consumption?

A: According to measured data, when processing PP sheets, the ADS system can achieve a stable output of 800-1000 kg/hour. Thanks to the intelligent PLC control system's precise adjustment of the host frequency, this equipment's energy consumption ratio (kWh/ton) is reduced by approximately 10%-15% compared to traditional models, making it an ideal choice for achieving green factories and low-carbon production.

Q5: Can recycled PP granules be directly used in injection molding or fiber drawing processes?

A: Yes. PP granules processed by the ACERETECH ADS system, due to their low ash content, uniform plasticization, and extremely low moisture content, fully meet the performance requirements of appliance casing injection molding, automotive parts manufacturing, and high-strength plastic woven bag fiber drawing, greatly enhancing the market premium of recycled materials.