Project Background

With the rapid development of the plastic recycling industry in Africa, local recycling companies face practical challenges such as complex raw material sources, high levels of contamination, and sensitivity to labor costs.

This customer wanted to build a washing and pelletizing production line that could process various plastic raw materials simultaneously, operate stably, and have controllable investment costs, in order to increase the added value of recycled plastics and expand their business scale.

After multiple rounds of technical communication and on-site condition assessment, ACERETECH customized a highly adaptable and automated plastic washing and pelletizing solution for the customer.

Raw Material Types

HDPE / PP rigid plastics

LDPE / HDPE film

PP non-woven fabric

PE / PP block materials

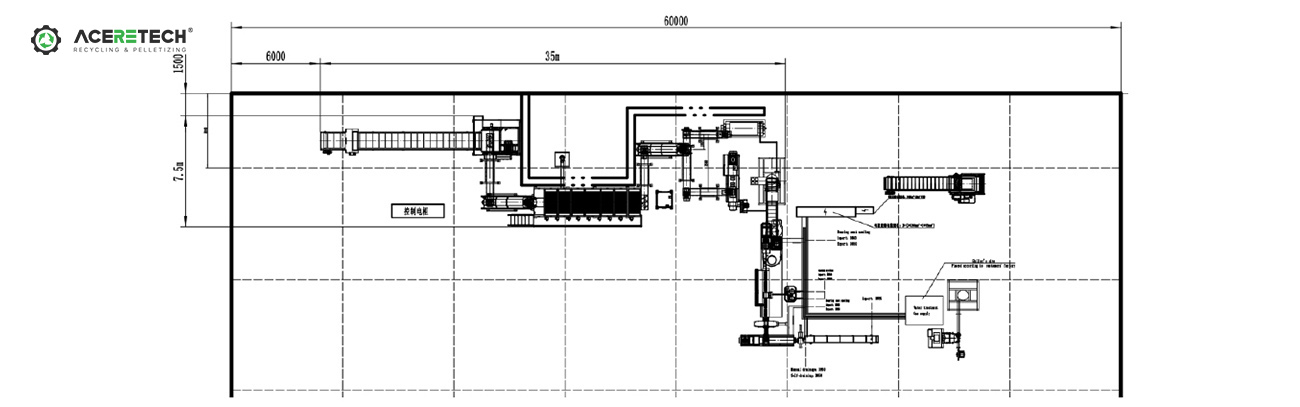

Solution Overview

This project adopts an integrated design of washing + two-stage pelletizing. Through a modular layout, it achieves co-processing of multiple raw materials, balancing capacity, stability, and energy consumption control, making it particularly suitable for the actual operating needs of recycling plants in Africa.

In the washing section, ACERETECH designed a multi-stage washing and intelligent protection structure to address the characteristics of multiple impurities and diverse forms of raw materials.

Process Flow:

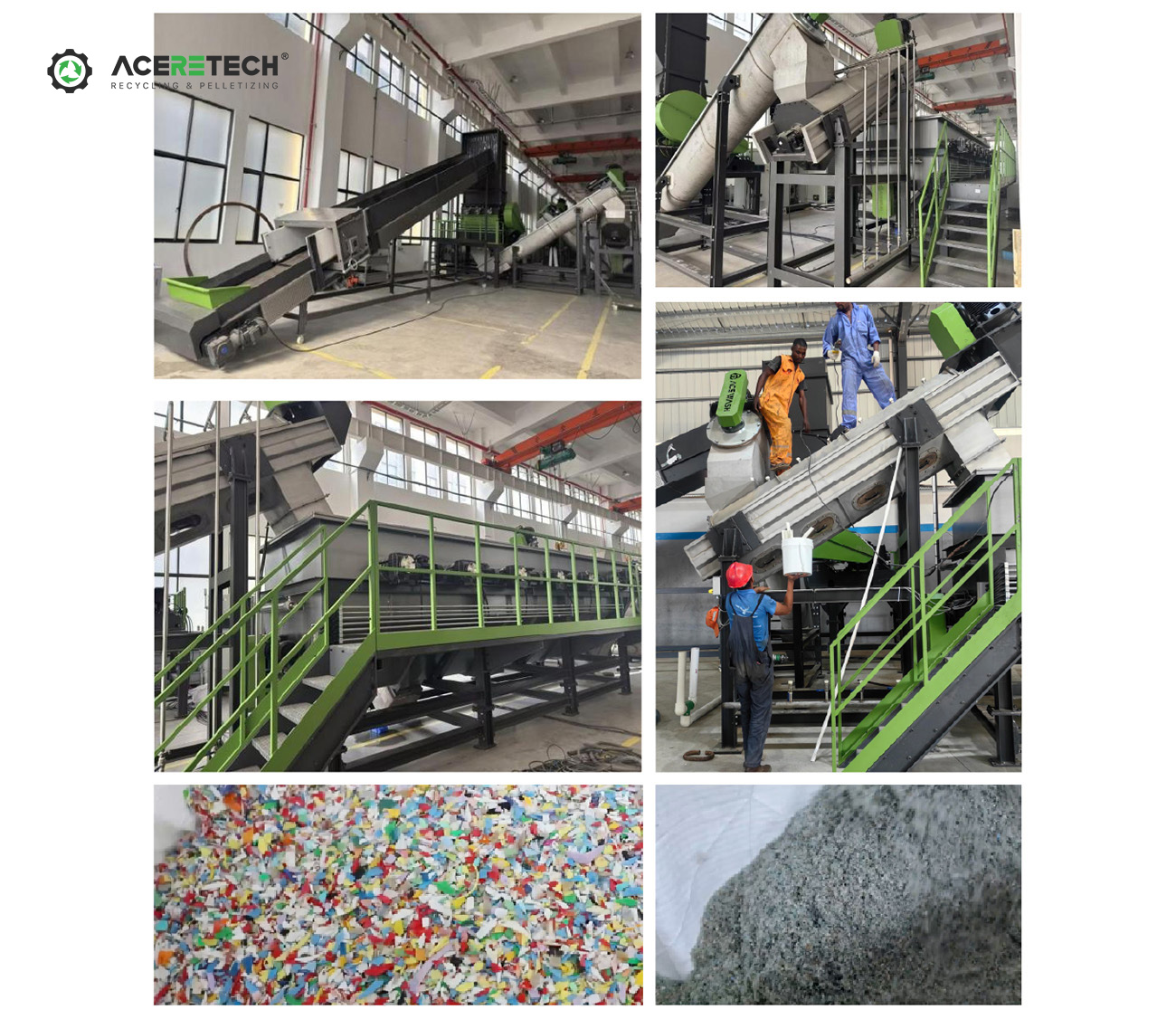

1. Conveying and Crushing

Materials enter the crusher through the conveying system.

A brand-name metal detector is installed at the front of the crusher to effectively prevent metal from entering and protect the core components of the equipment.

2. Primary Friction Washing

The crushed plastic enters a high-speed friction washing machine.

Efficiently removes oil stains, sand, label residue, and other contaminants.

3. Sink-Float Separation System

Density separation of plastics and heavy impurities is achieved through a water tank.

Improves the purity of the washed material.

4. Secondary Friction Washing

Further enhances the cleaning effect.

Provides stable and clean raw materials for subsequent pelletizing.

5. Drying System Dual-Channel Design:

Rigid plastics → High-efficiency dewatering machine

Soft film / non-woven fabric → Film extrusion dewatering machine

The entire washing system achieves continuous and automated operation, significantly reducing manual labor.

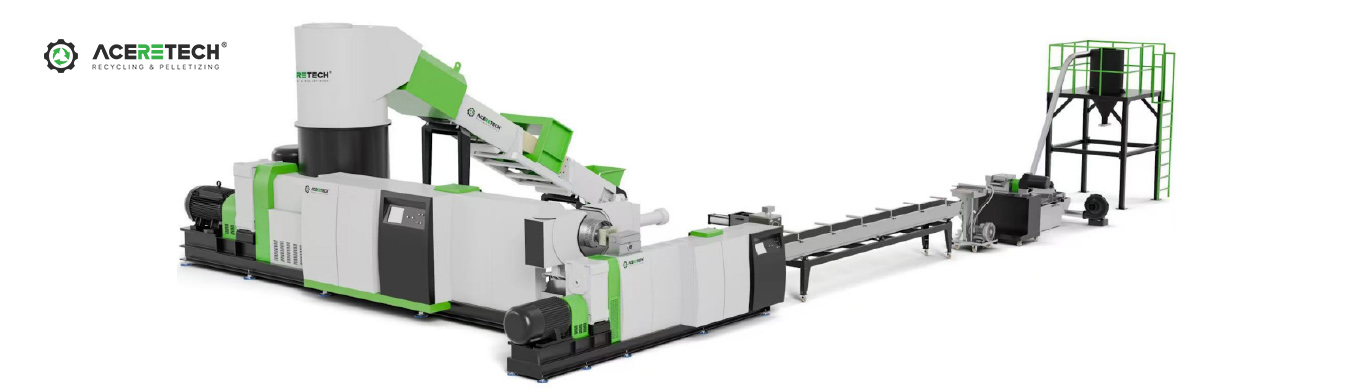

The washed plastic enters the two-stage extrusion pelletizing system, ensuring stable quality and low impurity content of the recycled pellets.

System Features:

Dual extruder structure for stable plasticization and deep degassing

Second stage provides further pressure equalization and filtration, improving pellet consistency

Advantages of the Integrated Compaction Design:

A single granulator can process both soft and hard materials

Eliminates the need for two separate granulation systems

Effectively reduces energy consumption, equipment investment, and maintenance costs

Project Results and Customer Benefits:

✔ One production line adapts to various raw materials, increasing factory operational flexibility

✔ High degree of automation and stable operation reduce reliance on manual labor

✔ Energy consumption and equipment investment are effectively controlled

✔ High cleanliness of recycled granules meets downstream application requirements

✔ Provides room for future upgrades and expansion for the customer

Customer Feedback:

“ACERETECH's solution successfully helped us solve the challenge of recycling mixed raw materials.

One production line can handle hard plastics, films, and non-woven fabrics, reducing equipment investment and operating costs.

After the project was put into operation, both production efficiency and recycled pellet quality met expectations, and we are already planning the next phase of capacity expansion.”