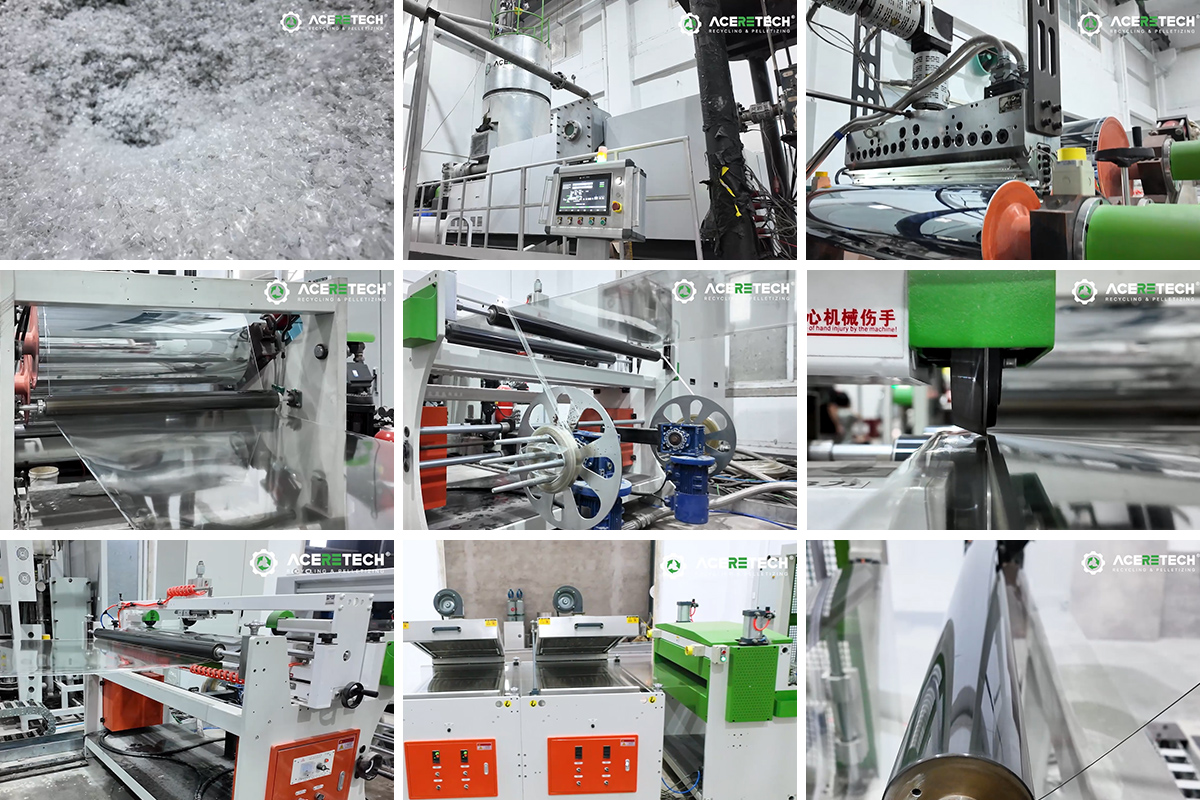

Milestone Achieved: Aceretech’s rPET Food-Grade Sheet Line Successfully Commissioned for South American Customer

We’re proud to share that Aceretech has successfully launched a turnkey rPET food-grade sheet extrusion line for a customer in South America. The line is now running stably, producing crystal-clear, FDA-compliant sheets from 100% recycled PET flakes — a major step toward sustainable packaging in the region.

This project wasn’t just about installing machines. It was about integrating six core innovations and over a dozen precision-engineered components into a seamless, one-step process — from flake to food-grade sheet.

Let’s take a closer look at what made this line not just functional, but exceptional.

The Secret’s in the Pre-Treatment: Reaction Chamber & Vacuum Valve

Most lines start melting right away. Ours doesn’t.

Before the PET flakes even reach the extruder, they pass through a high-speed reaction chamber with a 5-layer cutter plate system. Friction heat rapidly heats the flakes to ~160°C, vaporizing moisture and small molecules — all under vacuum, which pulls out impurities instantly.

This pre-purification step is critical for food-grade output. And it’s paired with a specially designed vacuum-sealed valve that:

- Controls material level and residence time

- Ensures stable, continuous feeding

- Prevents air leakage — a common issue in high-vacuum systems

It’s a small component, but it makes a big difference in melt stability.

Gentle Melting, Maximum Purity: Single-Screw Extruder with Dual Degassing

The PET-optimized single-screw extruder uses a special barrel and screw design to achieve mild plasticization — minimizing degradation, especially with recycled content.

And it doesn’t stop there:

- Two vacuum degassing zones remove residual volatiles

- Powered by a liquid ring + Roots three-stage pump for deep purification

- Result: cleaner melt, higher clarity, and better thermoforming performance

Stable Flow, Zero Downtime: Backflush Screen Changer & Melt Pump

To keep the line running 24/7:

- The large-area backflush screen changer reduces screen changes by up to 70%, with a superior sealing system that eliminates polymer leakage.

- It’s paired with a ZB-B-315CC melt pump (600kg/h), ensuring constant pressure and flow — crucial for uniform thickness.

Real-Time Quality Control: Online Melt Viscosity Monitoring

One of the most advanced features? The online melt viscosity system.

- Uses torsional vibration technology (no moving parts, no wear)

- Measures viscosity in real time — independent of temperature or flow

- Helps operators adjust parameters instantly

This isn’t just monitoring — it’s intelligent process control.

Precision Sheet Formation: T-Die & 3-Roll Calender

The T-die (950mm width) features:

- Chrome-plated cavity (HV900–1000 hardness) for durability

5-zone temperature control

- Adjustable lower lip for fine-tuning thickness (0.15–1.5mm)

Then comes the servo-controlled 3-roll calender:

- Rolls can run synchronized or independently

- Hydraulic gap adjustment with dial meter

- Full-body movement (up/down, forward/backward) for easy setup

Result? Perfect cooling, maximum transparency, and excellent dimensional stability.

Smart Downstream Configuration: From Trimming to Winding

The finishing line is fully automated and built for efficiency:

- Edge Trimming Unit: Two sets of pneumatic round blades, adjustable for widths up to 830mm

- Silicone Oil Coating: Single or double-side application with infrared drying (12KW total) to prevent sticking

- Haul-Off Unit: Servo-controlled (3.5kW), with static remover for clean surface transport

- Accumulator: PLC-controlled, allows continuous operation during roll changes

- Heavy-Duty Winder: Dual-position, handles rolls up to Ø1200mm, with precise length tracking

Every component is designed to minimize downtime and maximize yield.

Technical Snapshot

| Donec nec varius | 100% recycled APET, rPET, PETG, PLA, PP, HIPS flakes |

| Output Capacity | Up to 600 kg/h |

| Sheet Thickness | 0.15 – 1.5 mm |

| Max Sheet Width | 830 mm (effective 800 mm) |

| Layer Options | 1-, 2-, or 3-layer co-extrusion capable |

| Power Supply | 380V / 3-phase / 50Hz |

| Cooling Water | 12 m³/h at 25°C |

| Compressed Air | 1 m³/h at 0.6–0.9 MPa |

Proving That Turnkey Solutions Work — Across Borders

This successful launch reflects what we stand for: reliable technology, global support, and real-world results.

Whether you’re building your first rPET line or scaling up production, Aceretech delivers end-to-end solutions that work — not just in theory, but on the factory floor.

👉 Want to see how this line could work for your operation?

Contact us today to discuss your next project — and let’s turn plastic waste into value, together.