Multi-Layer Pipes Will Be The Application Area of Recycled Materials

.jpg)

Plastic pipes are widely used in water supply and drainage engineering, electric power and communication engineering, gas transmission engineering, agricultural irrigation engineering, industrial production and other fields in cities and buildings. In recent years, with the increase in infrastructure demand brought about by the advancement of my country's urbanization process and the expansion of the application field of plastic pipes, the output of plastic pipes in the country has achieved rapid growth.

From 2011 to 2018, the output of plastic pipes in my country increased from 10 million tons to 15.67 million tons, with an average annual growth rate of 6.63%. Public information shows that the overall production capacity of domestic plastic pipes has exceeded 30 million tons. There are more than 3,000 large-scale production enterprises in the industry, of which there are only less than 30 enterprises with an annual production capacity of more than 300,000 tons. And the production capacity of large enterprises accounts for a relatively small proportion.

At present, the market share of plastic pipes in various types of pipes in the country exceeds 50%. Among them, the output of PVC pipes is the leading product, accounting for about half of the total output of plastic pipes; the output of PE pipes and PP pipes is relatively small, the output of PE accounts for about 30% of the total output of plastic pipes, and the output of PP pipes accounts for about 10% of the total output of plastic pipes.

Rigid polyvinyl chloride (PVC-U) water supply and drainage pipes are the best-developed plastic pipes in my country. The product uses PVC resin as the main raw material, and adds necessary additives (including heat stabilizers, processing aids, lubricants, etc.) to process and form the pipeline system. The connection method mainly adopts two methods: special glue bonding and rubber ring flaring socket.

.jpg)

PE water supply and gas pipelines gradually emerged in the late 1980s with the development of special materials for high-density polyethylene (HDPE) pressure pipelines. By adding comonomers such as butene and hexene in the polymerization, the long-term compression resistance of polyethylene materials is improved. The connection methods of PE pipes are mainly hot-melt socket, hot-melt butt and electrofusion connection..jpg)

PP-R pipeline is the random copolymerization PP-R obtained by adding ethylene monomer with a content of not more than 2% and propylene to random copolymerization of PP raw materials during the preparation process. The low temperature brittleness of ordinary PP is improved, and the long-term hydrostatic strength and high temperature resistance strength of the product are improved at the same time. The connection of PP-R pipes mainly adopts the way of hot-melt socket connection..jpg)

Aluminum-plastic composite pipe is a composite pipe of metal and plastic. The inside and outside are plastic layers, the middle is aluminum layer, and the middle of plastic and aluminum layers is bonded with a layer of hot melt adhesive. The connection of aluminum-plastic pipes is generally made of copper parts..jpg)

Double-wall corrugated pipes and winding pipes are also relatively well-developed plastic pipe varieties in my country. They belong to structural wall pipes, and the difference from ordinary solid wall pipes lies in the existence of inner and outer wall structures. Mainly used for buried drainage or communication pipes, the diameter can be more than 3m.

The inner wall is a smooth structure in order to meet the needs of conveying fluid, and the outer wall is made into a corrugated or hollow structure in order to meet the needs of buried resistance to external pressure. Structural wall pipes can save raw materials while meeting the requirements of use. Compared with the same solid wall pipes, structural wall pipes can save 30%-50% of raw materials. The raw material can be PVC or HDPE. The connection mainly includes rubber ring sealing connection, heat shrinkable tape welding, etc.

.jpg)

In addition to the above-mentioned plastic pipes, some other plastic pipes include sheath pipes for power transmission and chlorinated polyvinyl chloride (PVC-C) for chemical use, acrylonitrile-butadiene-styrene copolymer (ABS). ) pipes, PE pipes and HDPE silicon core pipes for optical fiber and communication jackets, polyphthalamide pipes for the automotive, mechanical and pneumatic industries and cross-linked polyethylene (PE-X) pipes for floor heating , polybutene (PB) pipes and heat-resistant PERT pipes, etc.

The European Plastics Pipe Manufacturers Association (TEPPFA) has pledged to use 250,000 tons of recycled material per year by 2020. Sponsor programs in Europe may mandate the use of recycled materials to replace more virgin feedstocks in the near future.

At present, some pipeline recycled materials are used in non-pipeline and some non-pressure pipelines, and the use of recycled materials is still not allowed in all pressure pipeline systems. Multilayer piping systems will be one possible application area for recycled material. Co-extruded multi-layer pipes that partially use recycled materials have similar durability to conventional pipes.

In the process of upgrading new products of plastic pipes, the appearance of modified materials and new materials will be faster. Gradually shift from single material processing to modified composite materials to improve certain characteristics or comprehensive performance of pipelines. At the same time, advanced engineering installation technologies such as trenchless technology, underwater laying technology, sand-free laying technology, and large-diameter pipeline connection technology will be widely used.

.jpg)

.jpg)

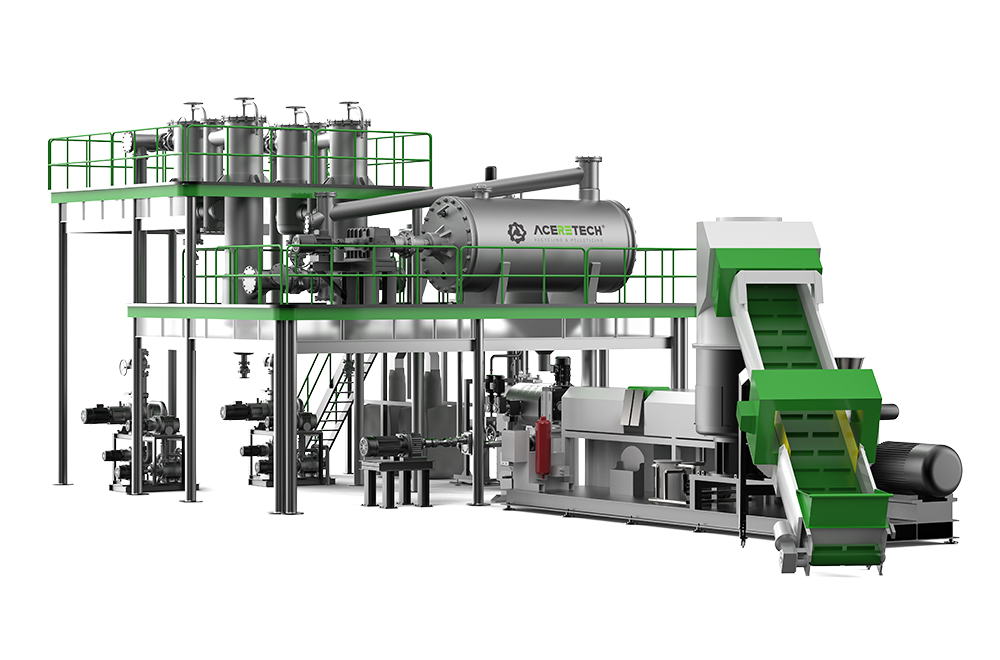

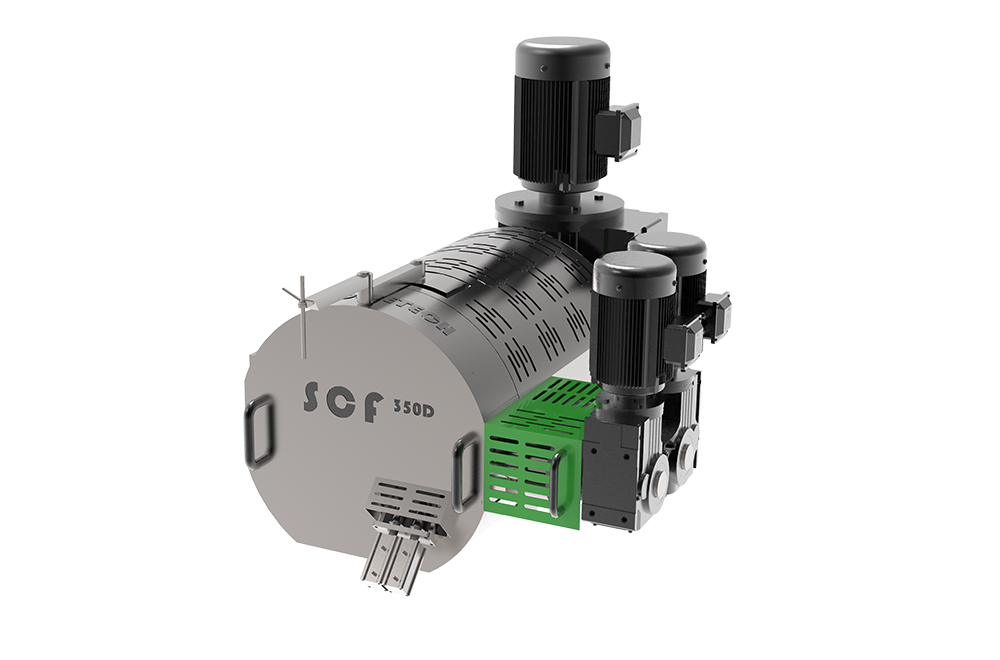

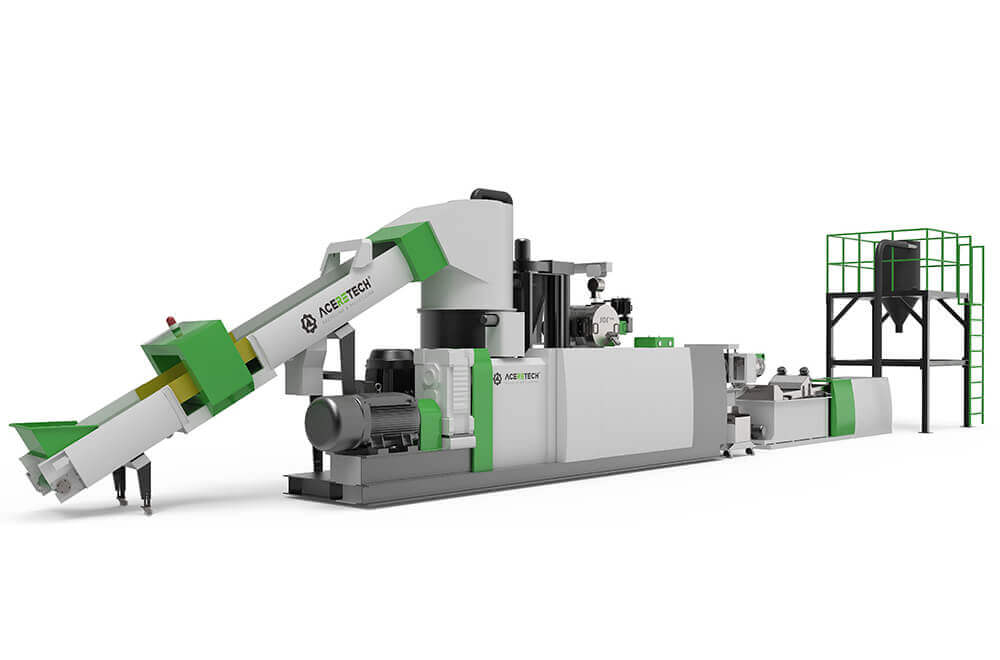

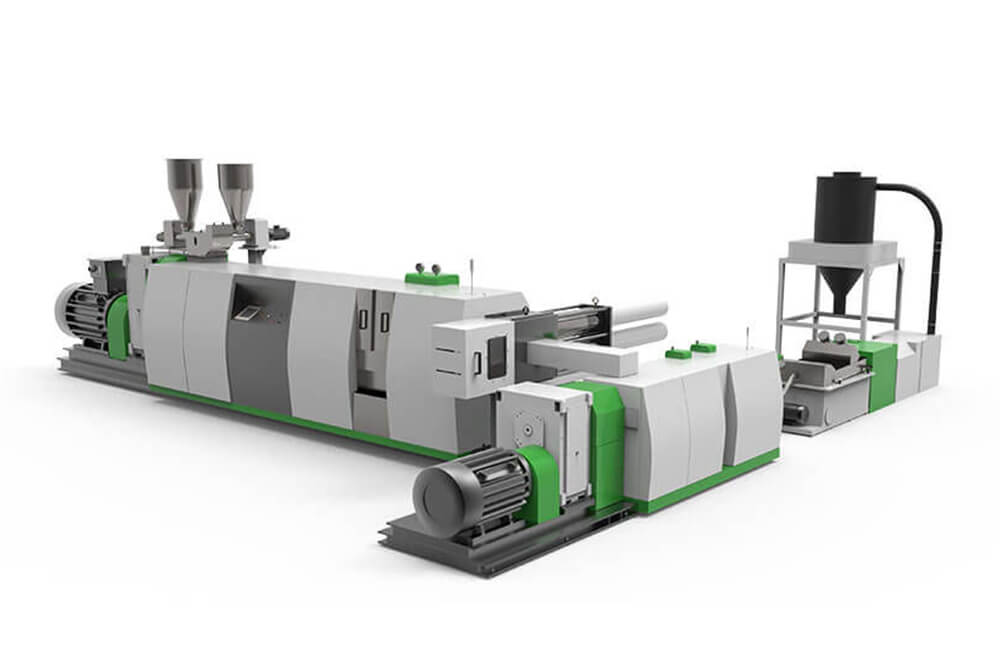

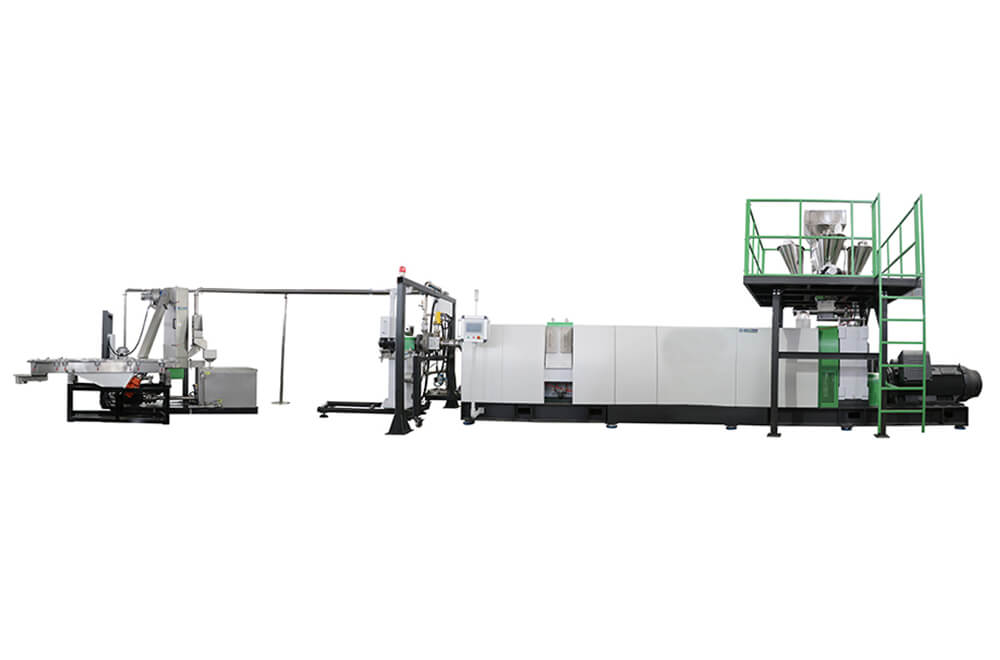

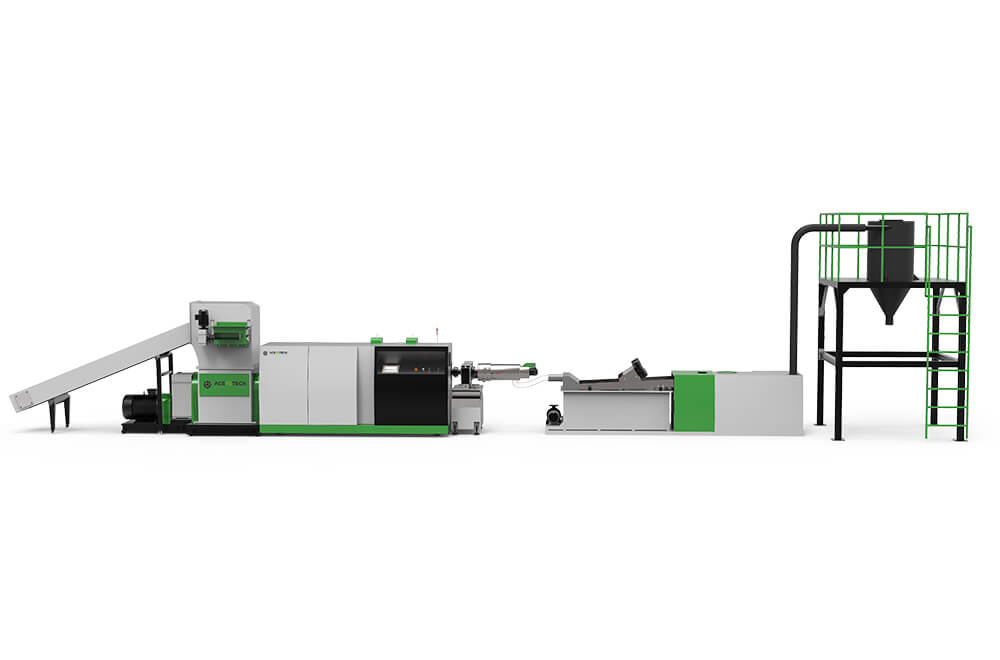

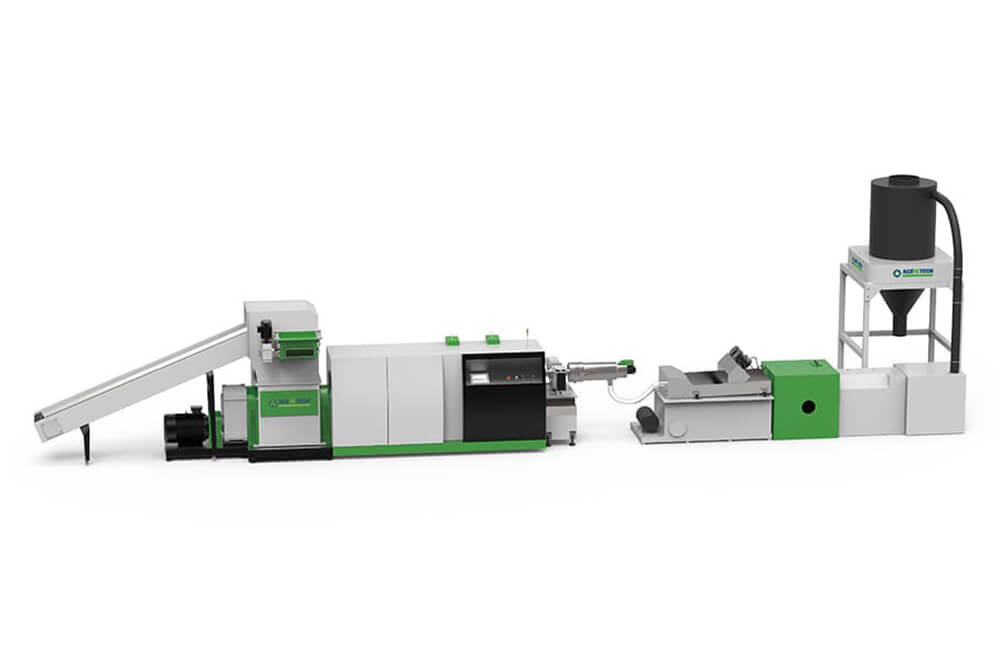

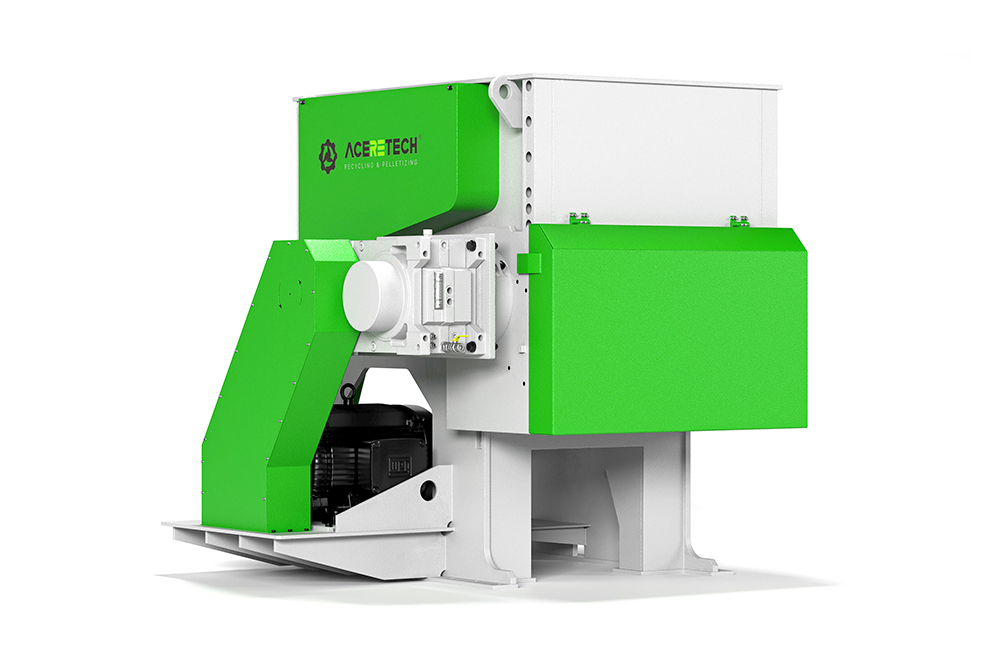

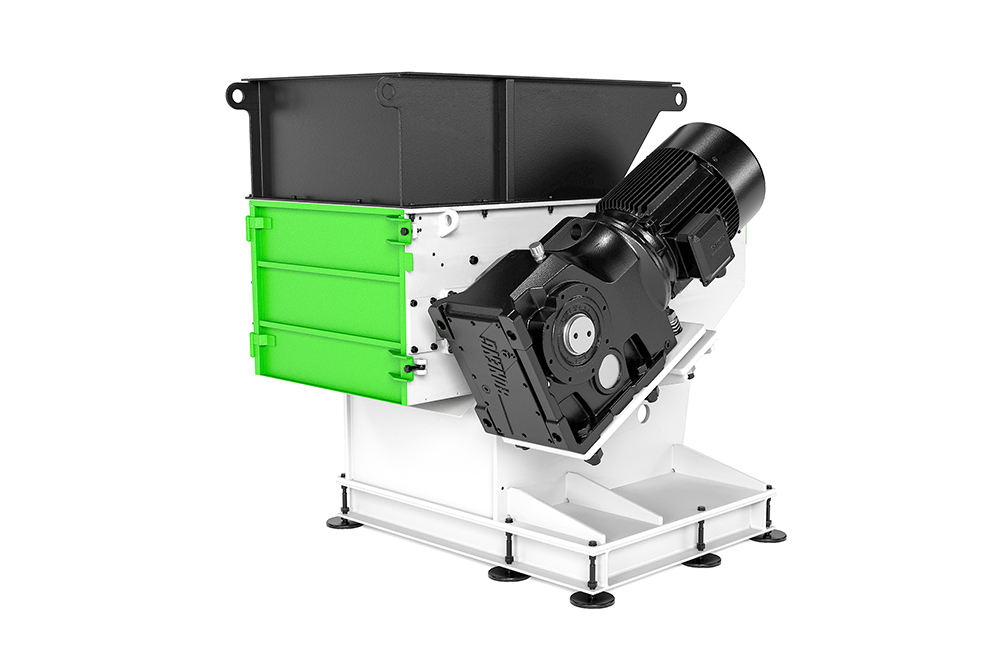

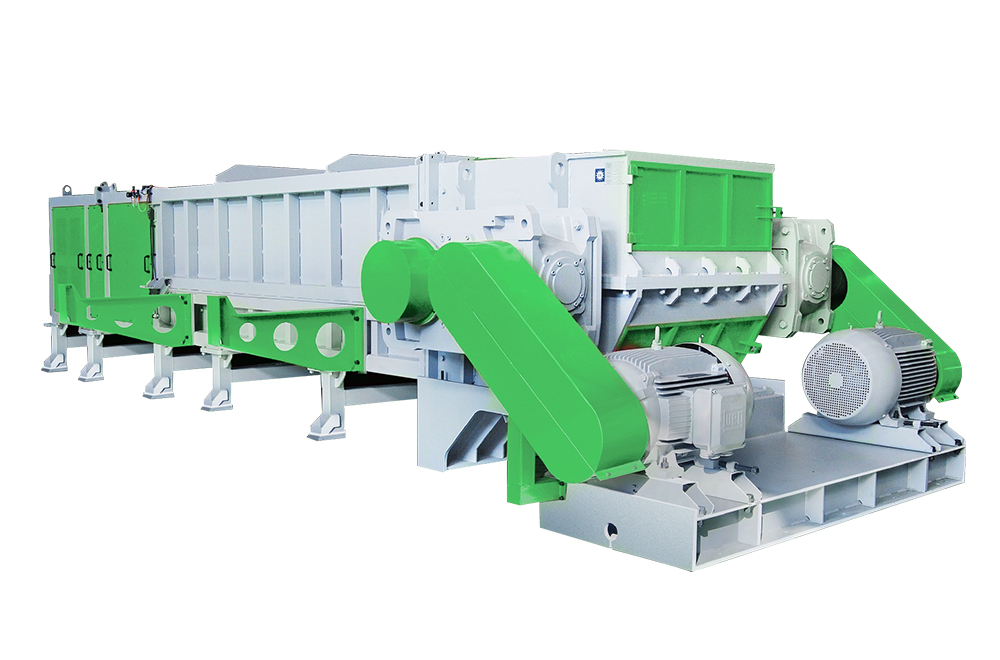

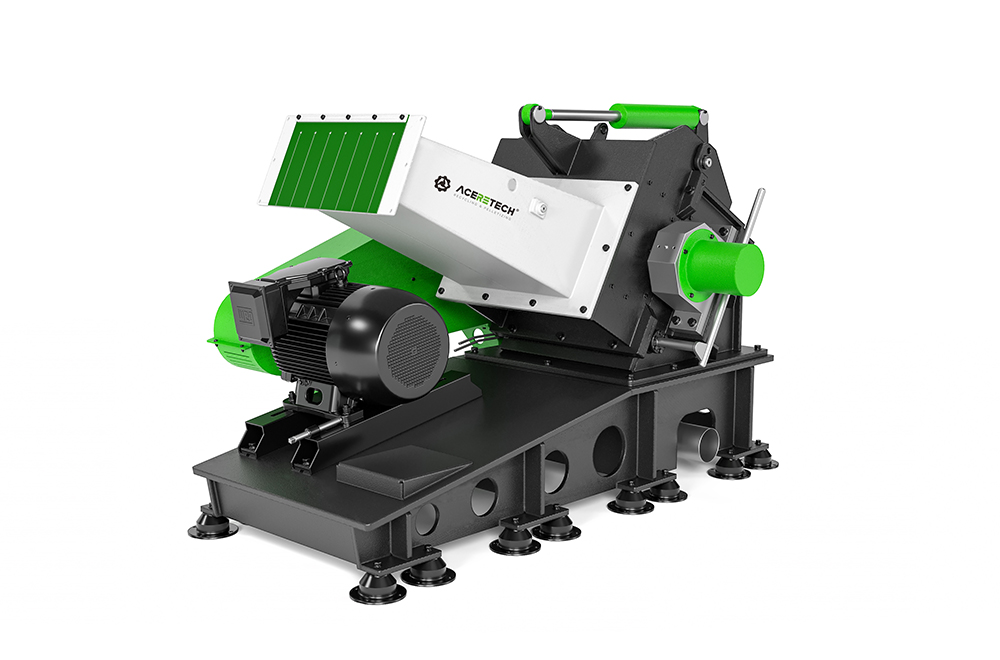

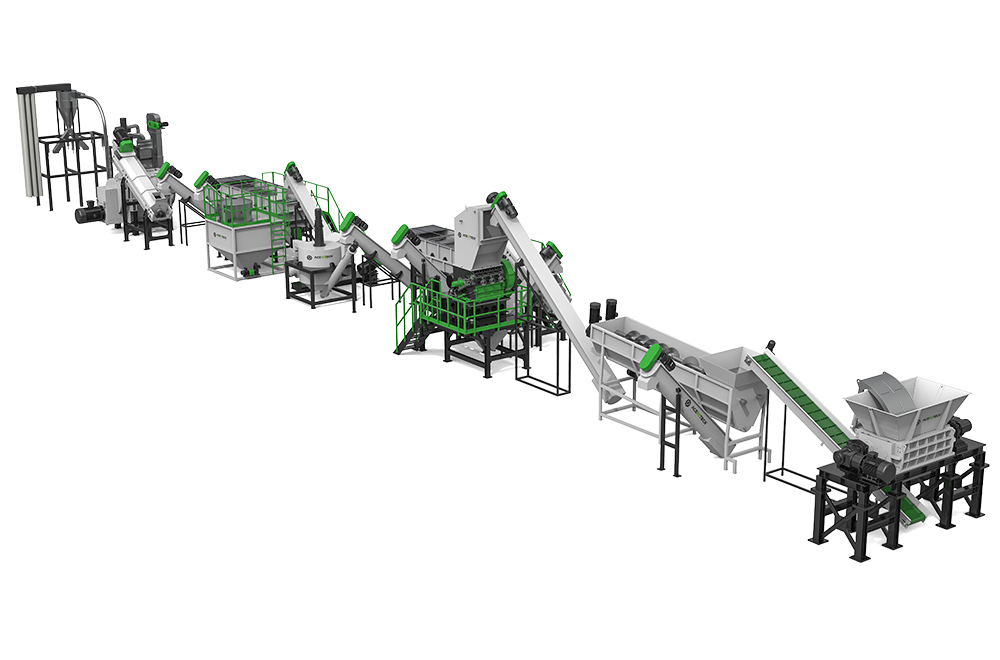

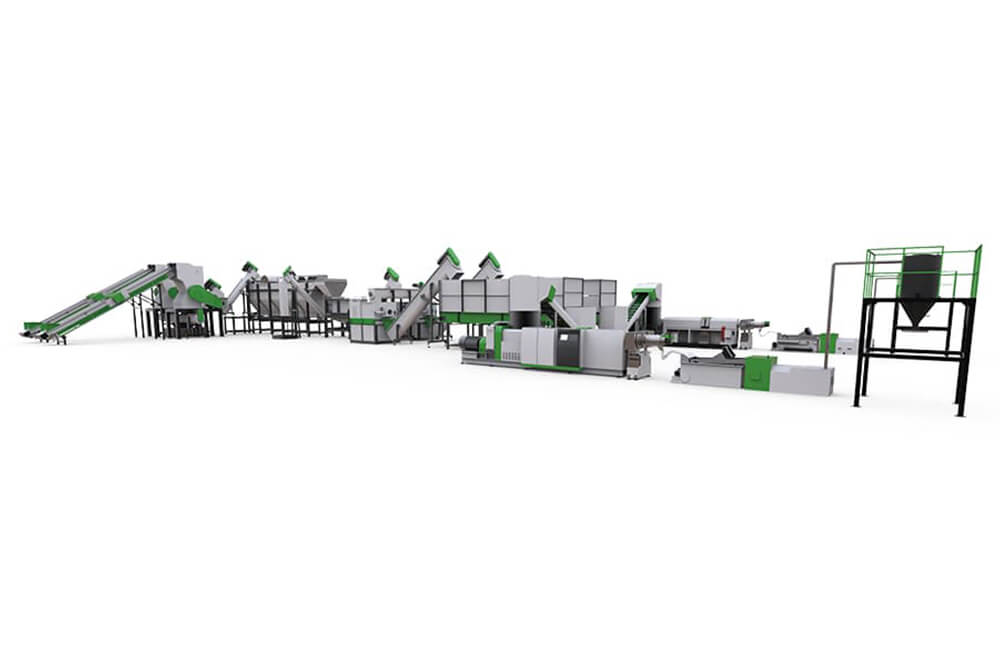

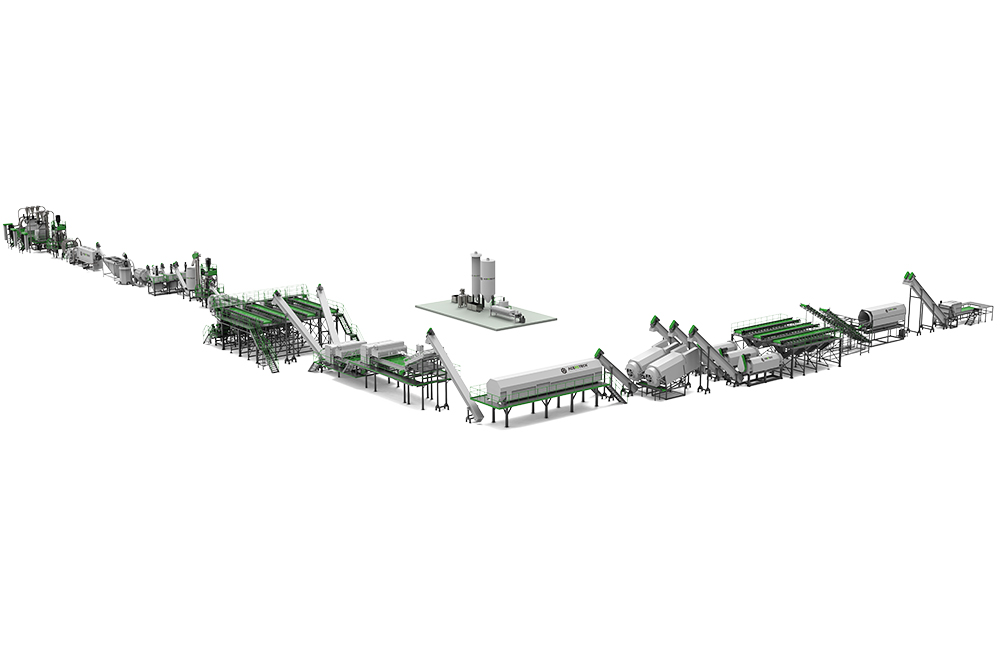

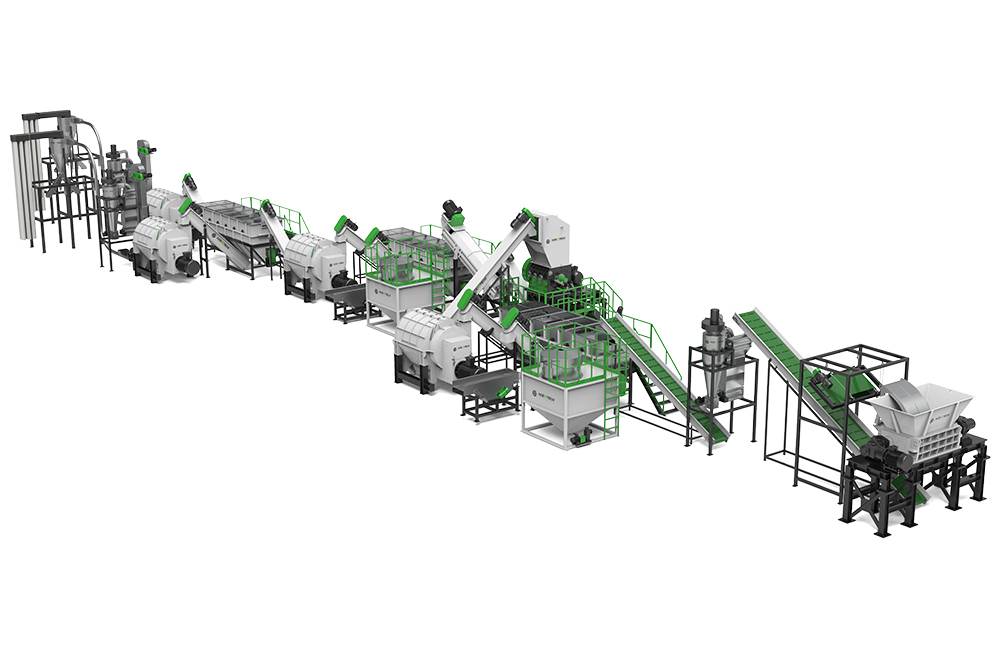

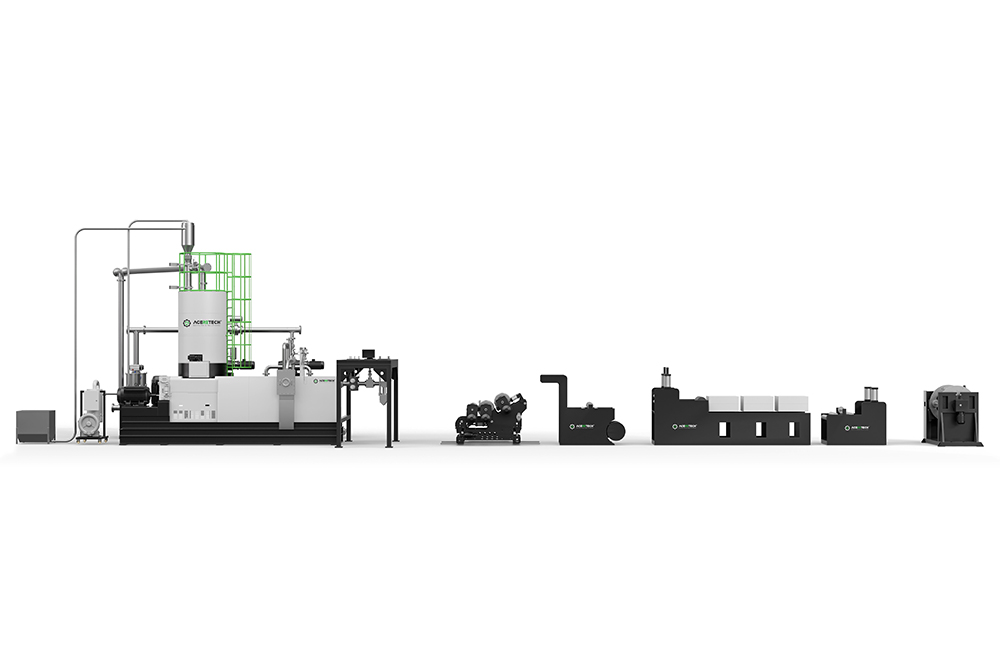

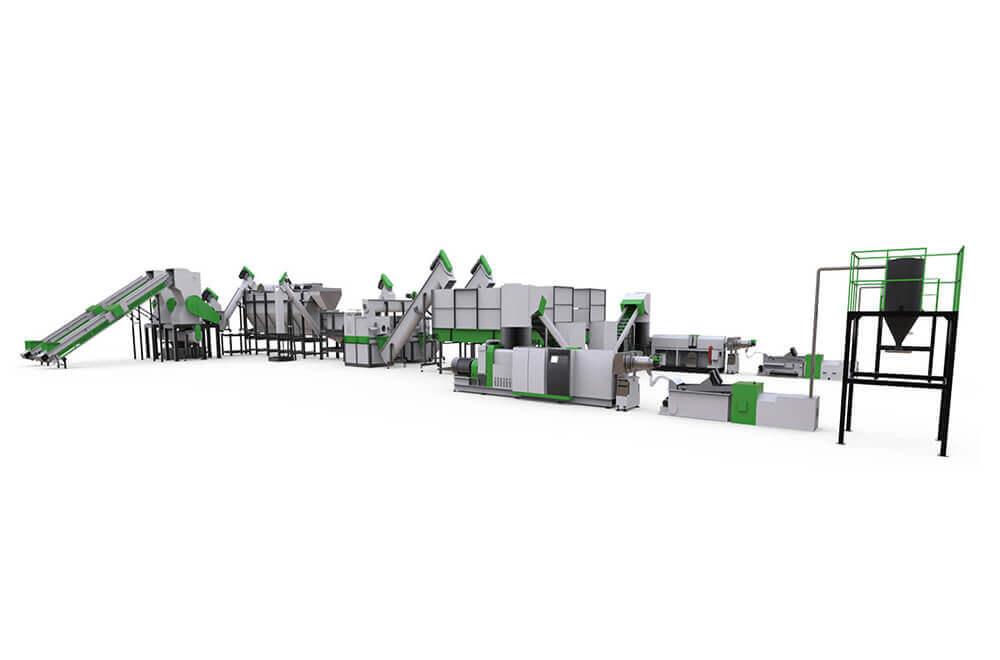

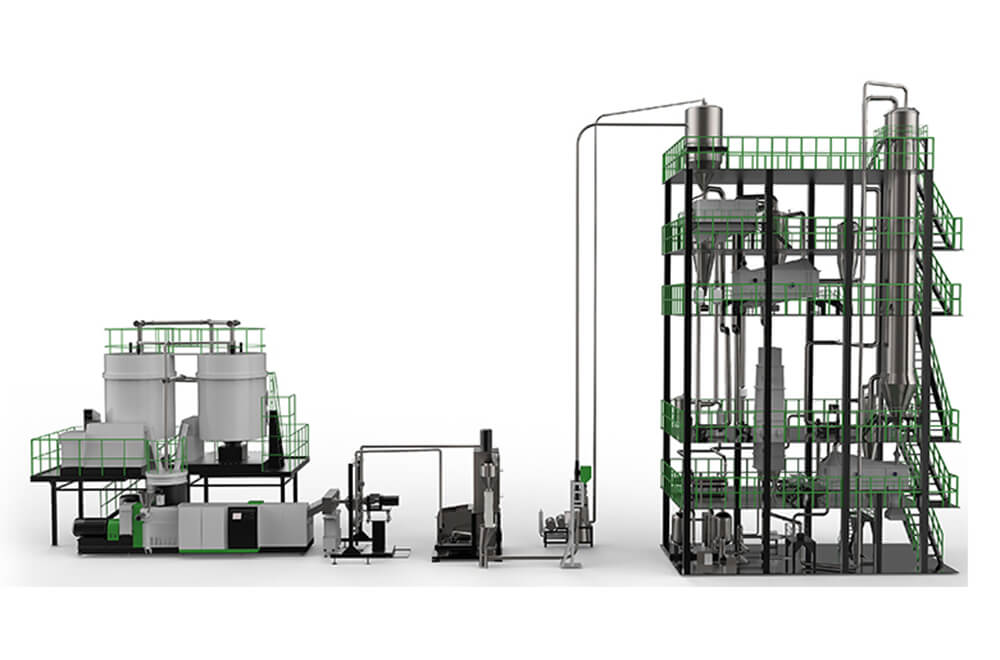

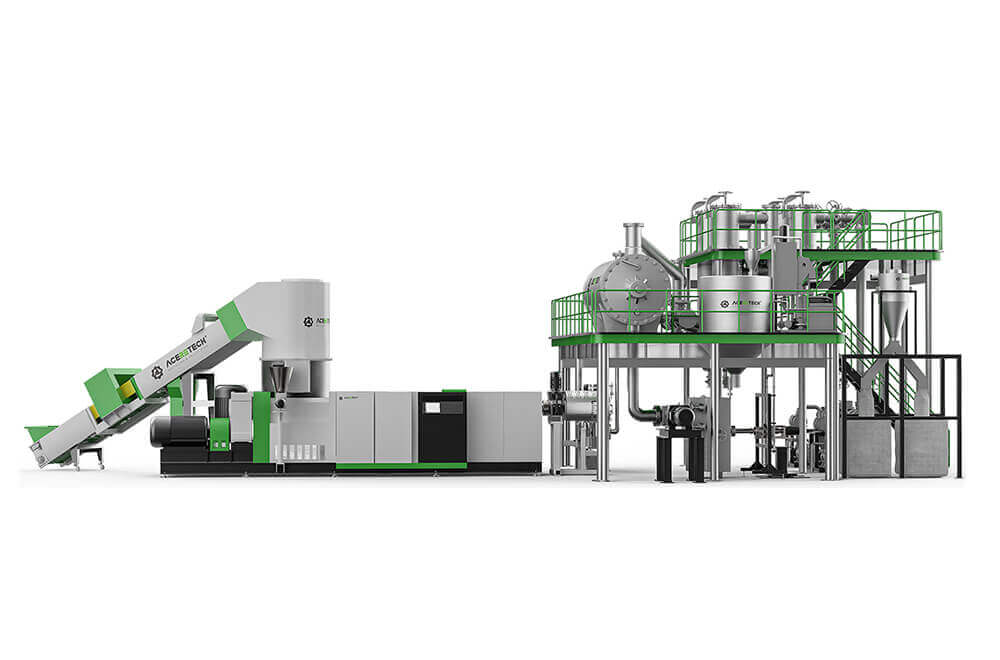

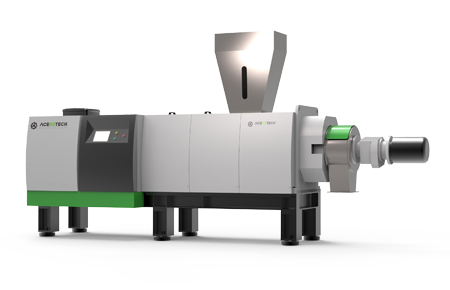

JIANGSU ACERETECH Machinery Co., Ltd. is a professional manufacturer of plastic recycling equipment. For the waste plastic pipes generated in the production process of plastic pipes, ACERETECH has developed and produced a shredder for large-diameter pipe recycling and a crusher for small-diameter pipe recycling, including the later recycling pelletizing equipment. ACERETECH will provide you customized shredding, crushing, and pelletizing solutions.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact Us

Contact Us